Device for expansion corrugated pipes

A technology of bellows and expansion position, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc. It can solve the problems of bellows or bellows strings that cannot be expanded, and the gap is narrow, so as to improve the service life, use safe and reliable, strengthen performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

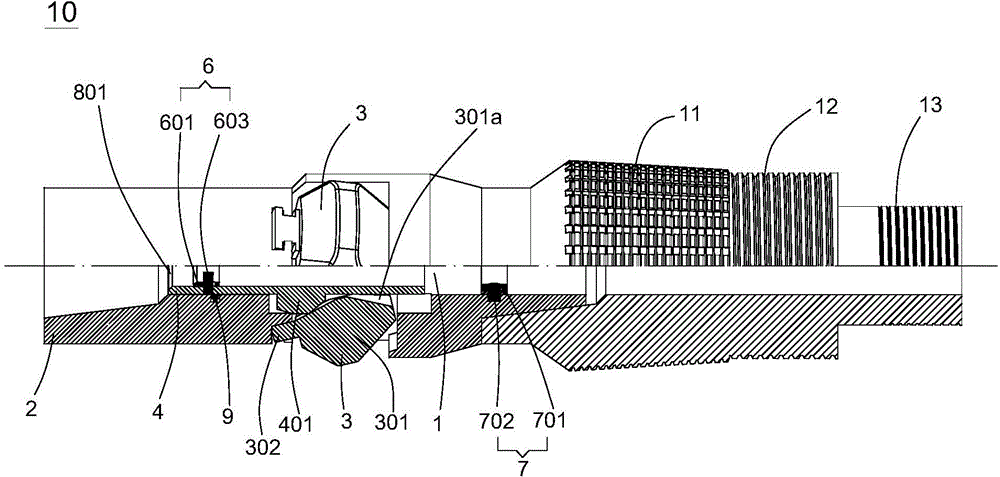

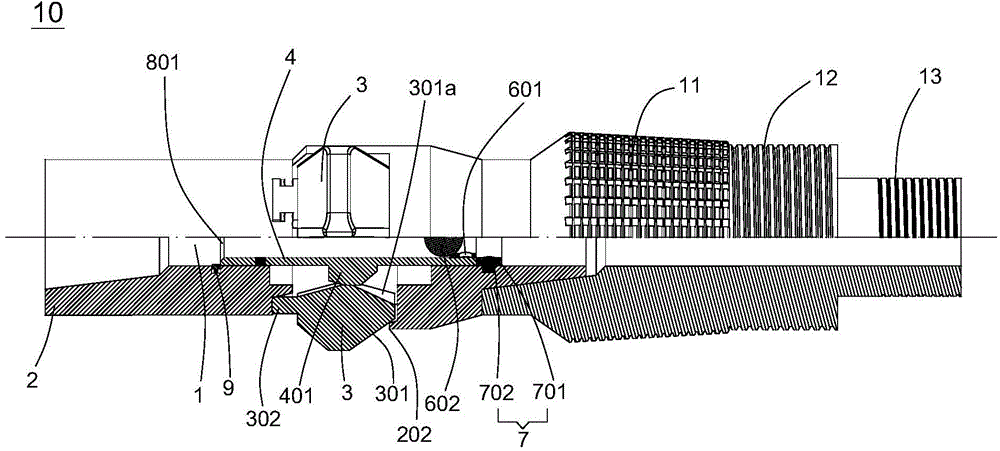

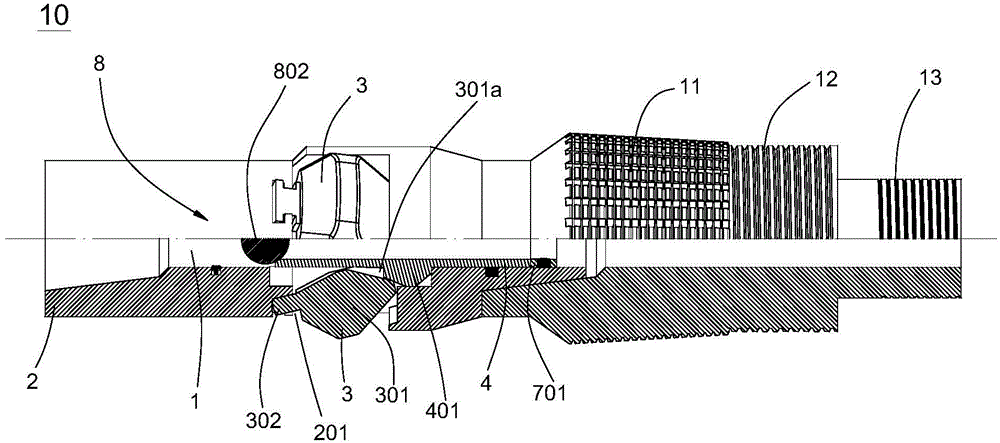

[0030] The present invention will be further described below in conjunction with accompanying drawing.

[0031] Figures 1 to 3 The device 10 for expanding bellows according to the invention is shown in three operating states. The device 10 is mainly used to complete the expansion of the bellows and the trimming of the inside of the bellows during drilling. The device 10 comprises a housing 2 having a cavity 1, Figure 4 is also shown at the same time. Housing 2 is generally tubular, and its upstream end (such as Figure 1-3 on the left side) can be used to connect the running tool, while the downstream end (such as Figure 1-3 to the right) for connecting bellows or bellows strings. The inner chamber 1 can be configured as an approximately cylindrical axial chamber.

[0032] According to the invention, the device 10 also includes a plurality of expansion cones 3 arranged in the peripheral wall of the casing 2, which Image 6 is also shown at the same time. The plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com