Drum type - poor balance pumping unit

A technology of drum type and pumping unit, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of waste of power resources, large shutdown loss, high difficulty of operation, etc., so as to reduce operation and mechanical load wear The effect of prolonging and prolonging the pump inspection period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

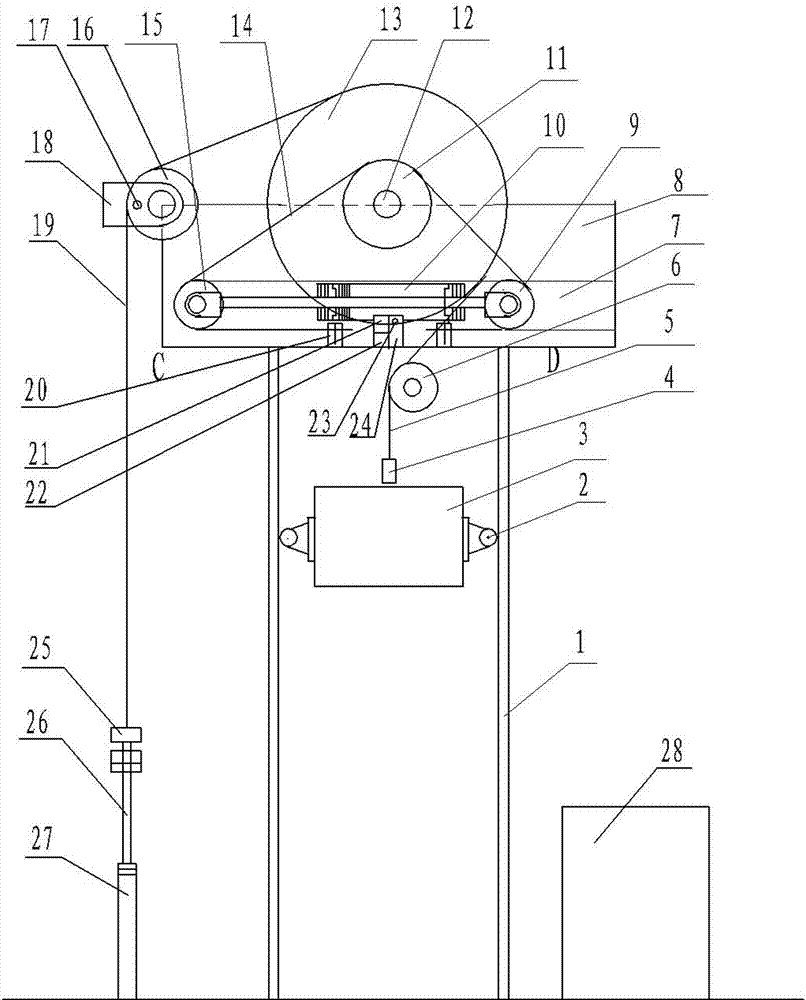

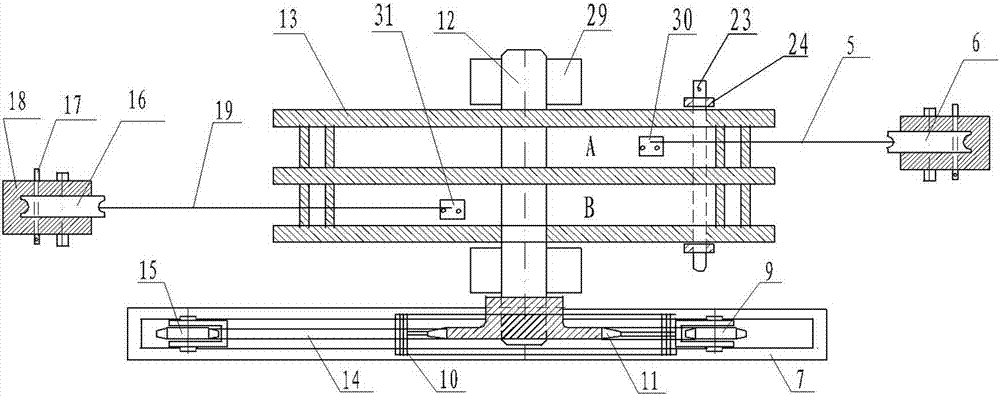

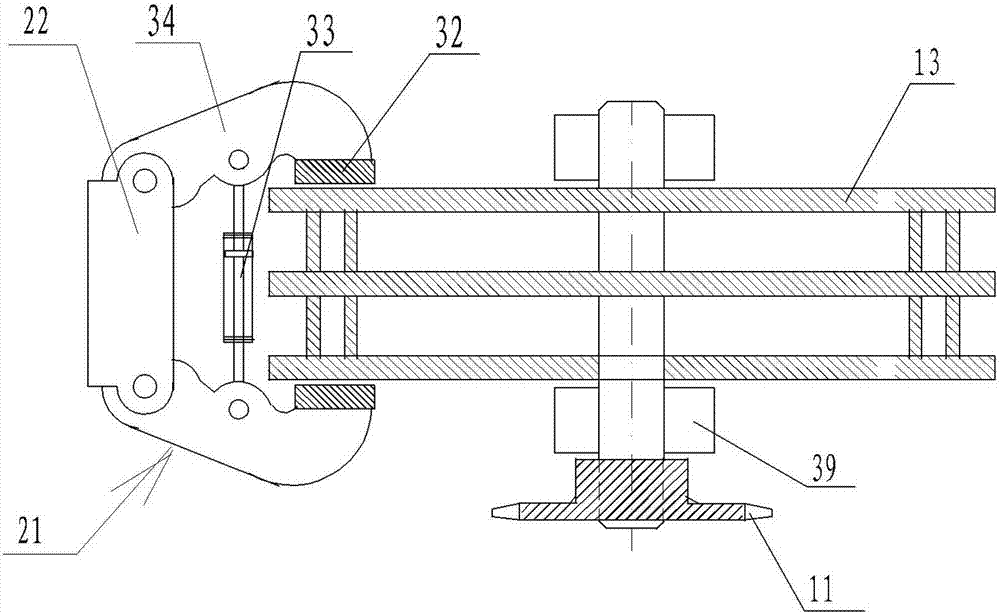

[0041] Drum type-poor balance pumping unit, including tower four-column leg slideway 1, main engine platform 8, hydraulic cylinder 10, cylinder front end movable pulley 15, oil cylinder rear end movable pulley 9, front support wheel 16, rear support wheel 6, body drum 13 , counterweight iron 3, sucker rod 26, hydraulic braking device 21, hydraulic pump station 28. The main engine platform 8 is arranged above the four-column leg slideway 1 of the tower, and the same body roller 13 and hydraulic cylinder 10 are both arranged on the main engine platform 8 . The hydraulic cylinder 10 is a through-rod two-way oil cylinder, and the front and rear ends of the piston rod passing through the oil cylinder are respectively connected to the movable pulley 15 at the front end of the cylinder and the movable pulley 9 at the rear end of the cylinder, and the movable pulley 15 at the front end of the cylinder and the movable pulley 9 at the rear end of the cylinder are slidably connected to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap