Cutting part of an internal spray roadheader

A technology of roadheader and cutting part, which is applied in the field of cutting part of internal spray roadheader, which can solve problems such as poor effect, ineffective treatment of respirable dust, and damage to the health of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

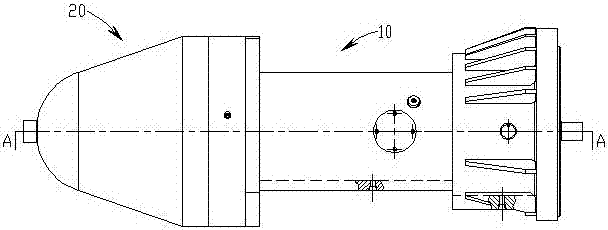

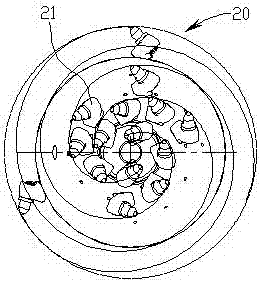

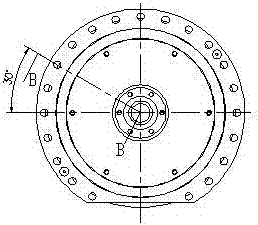

[0015] see figure 1 - Image 6 , a cutting section of an internal spray type roadheader of the present invention, comprising a cantilever section 10 and a cutting head 20, the outer circumference of the cutting head 20 is provided with a pick 21 in a spiral manner, the cantilever section 10 is equipped with a main shaft 1, and the main shaft One end of 1 is connected with deceleration mechanism 2, and the circumference of one end of said cutting head 20 is connected with ring gear 23 by bolt 22, and the other end of said main shaft 1 cooperates with ring gear 23 through planetary gear 3, and planetary gear 3. A planetary wheel shaft 31 is fixed inside; the cantilever section 10 includes an arm cylinder section 11 positioned outside the cutting head 20 and a cantilever shaft section 12 placed inside the cutting head 20. The cantilever shaft section 12 is equipped with a cantilever bearing 13, The cantilever bearing 13 is equipped with a bearing cup cover 15 and a bearing cup 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com