Filling device used for constant-temperature and constant-pressure continuous chemical charging of micro combined solid pushing engine

A constant temperature and constant pressure filling device technology, which is applied in the direction of rocket engine devices, jet propulsion devices, machines/engines, etc., can solve the problems of high risk, difficulty in controlling the amount of charge, and time-consuming rework, etc., and achieve low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

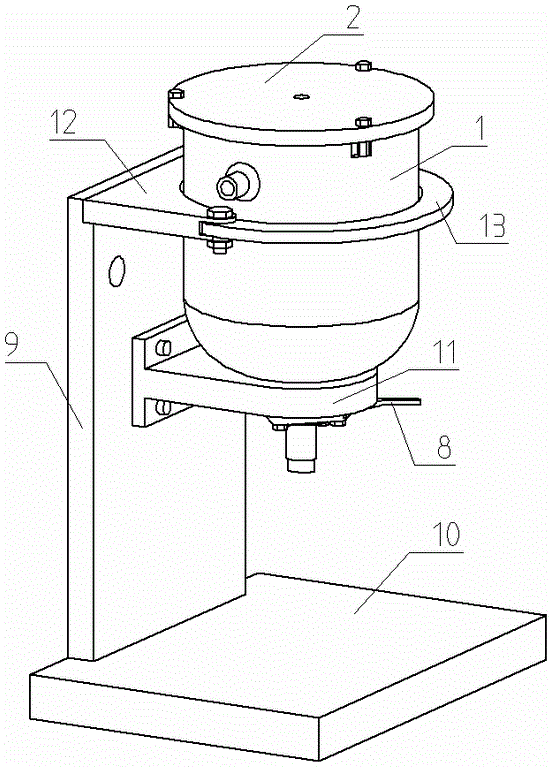

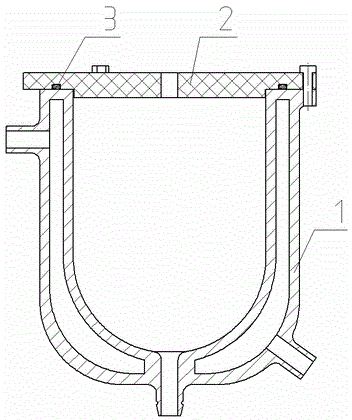

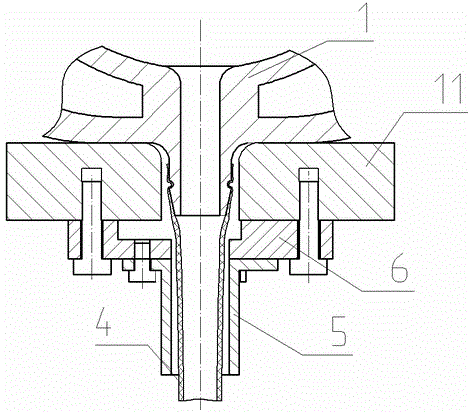

[0026] figure 1 , 2 Among them, the present invention includes a hopper mechanism that can realize sealing and constant temperature and pressure, a rubber hose valve mechanism for safe diversion and throttling, and an E-shaped support frame mechanism for connecting and fixing the hopper mechanism and the rubber hose valve mechanism. The hopper 1 of the hopper mechanism is a welded cavity wall structure (jacket structure). The upper end of the cavity wall hopper 1 is equipped with a transparent plexiglass cover plate 2, and the center of the cover plate 2 has a threaded hole communicating with the inner cavity of the hopper. , The port of the hopper 1 is connected with the cover plate 2 by bolts, and the sealing ring 3 is embedded in the annular groove of the cover plate 2 to realize sealing. The quick-plug connector connected to the threaded hole of the cover plate 2 is connected to the inlet pipe leading to nitrogen, so that the high-viscosity slurry in the hopper 1 can be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com