Rotary connector

A technology of rotary connectors and adapters, which is applied in the direction of shaft couplings, rigid shaft couplings, mechanical equipment, etc., can solve the problems of limited service life of shaft bearings, narrow shaft bearings, and influence on signal transmission, etc., to improve radial The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

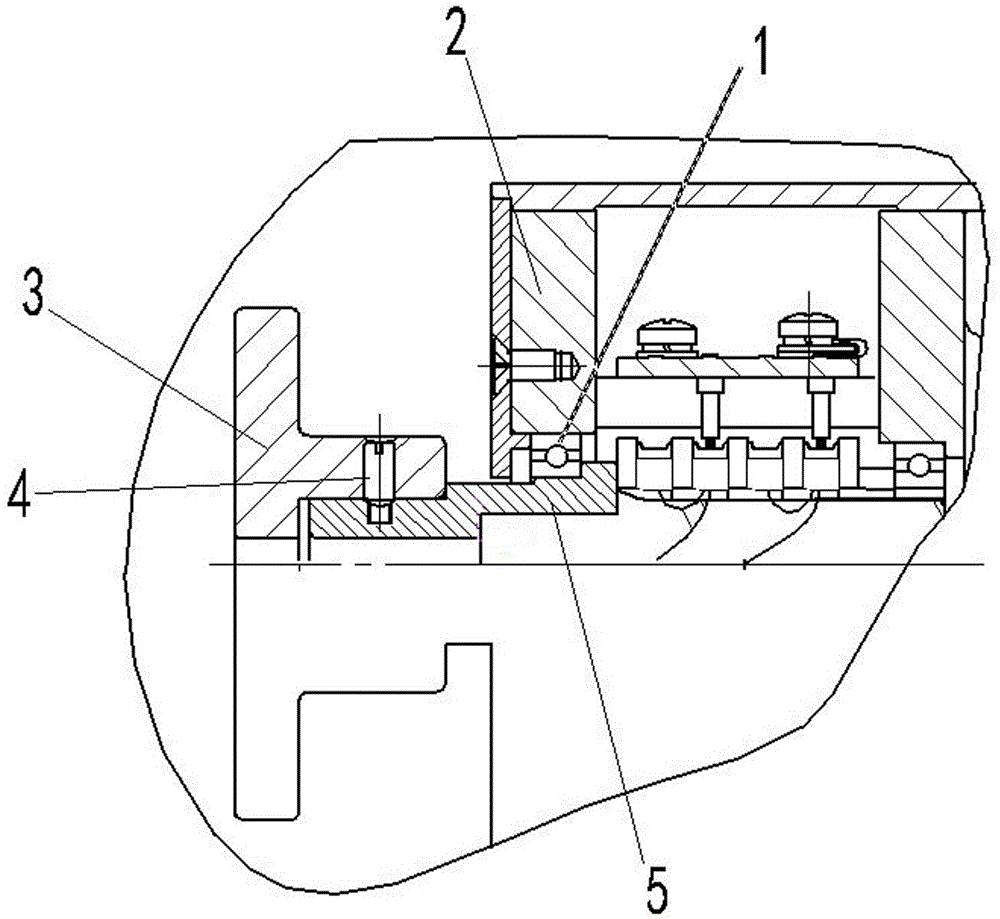

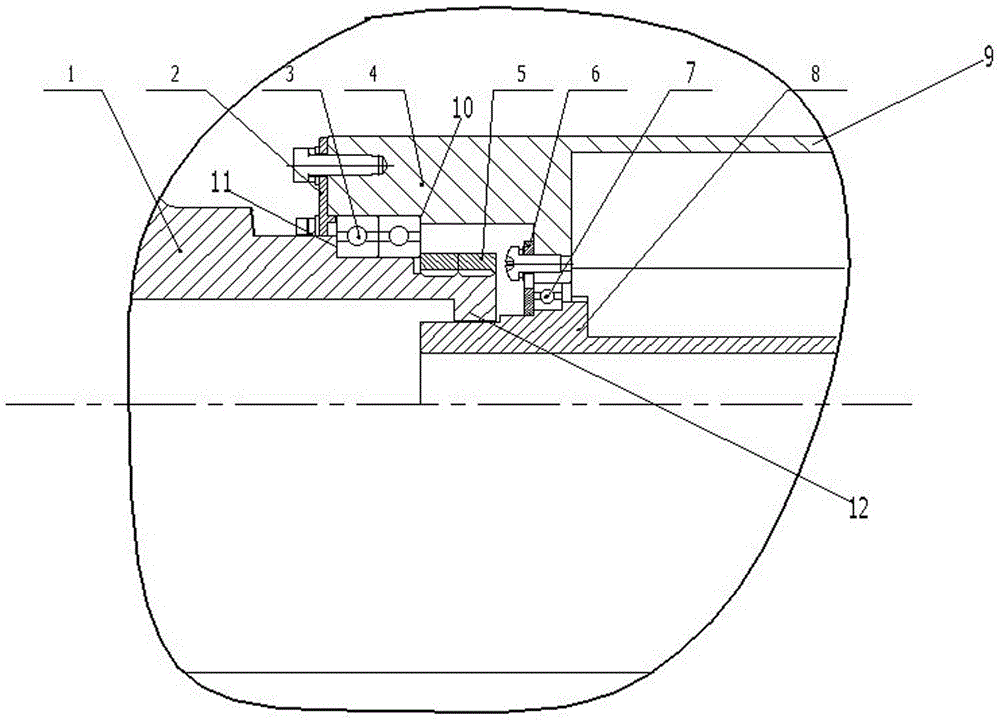

[0014] Examples of swivel connectors are figure 2 As shown: the rotary connector in this embodiment is an electric rotary connector, including a support frame 9 and an adapter 1, and the support frame 9 is equipped with a rotating shaft 8 whose rotation axis extends in the front and rear direction through the rotating shaft bearing 7, and the support frame 9 The front end has a bearing installation sleeve 4, the rear end of the adapter 1 extends between the bearing installation sleeve 4 and the rotating shaft 8, the rear end of the adapter 1 is connected to the rotating shaft 8 through a key and a keyway structure 12, and the adapter 1 in the radial direction 1 is not in contact with the rotating shaft 8. The adapter 1 is rotatably assembled on the support frame through the adapter bearing 3. In this embodiment, the adapter bearing 3 is a double bearing structure located between the bearing mounting sleeve 4 and the rear end of the adapter. The inner wall of the bearing inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com