Novel inflating structure for airbag inflator

A buffer air bag and inflatable structure technology, applied in mechanical equipment, container manufacturing machinery, container filling methods, etc., can solve problems such as affecting the inflation efficiency, air leakage of the air cushion film, affecting the cushioning effect of the air cushion film, etc. Buffering effect, effect of preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

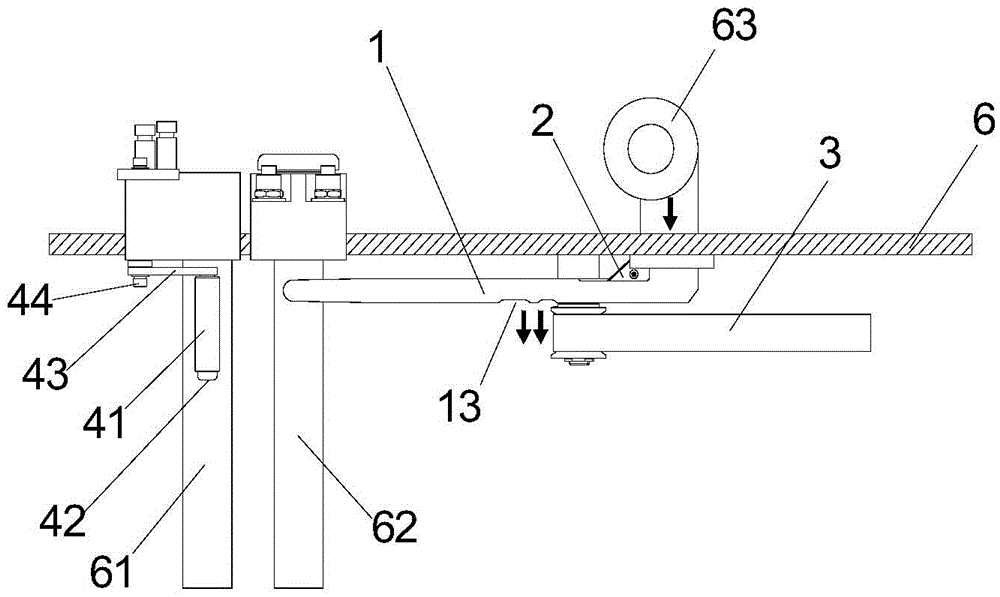

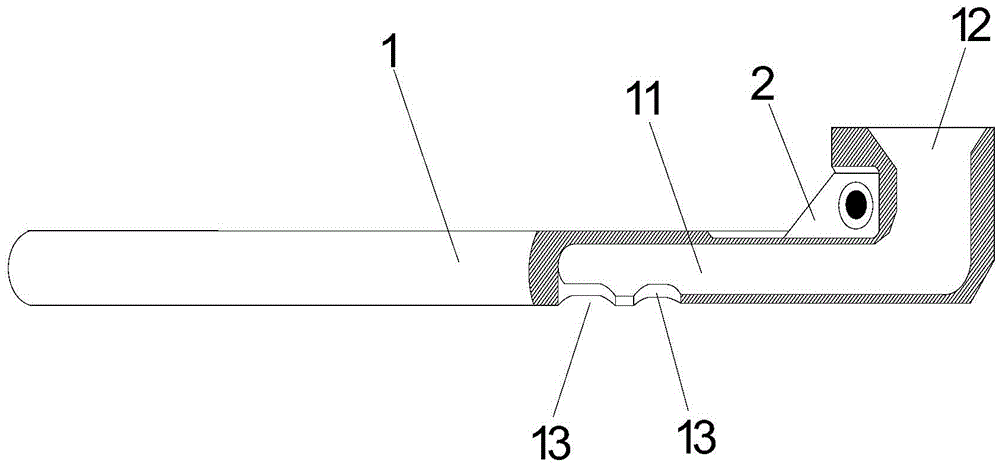

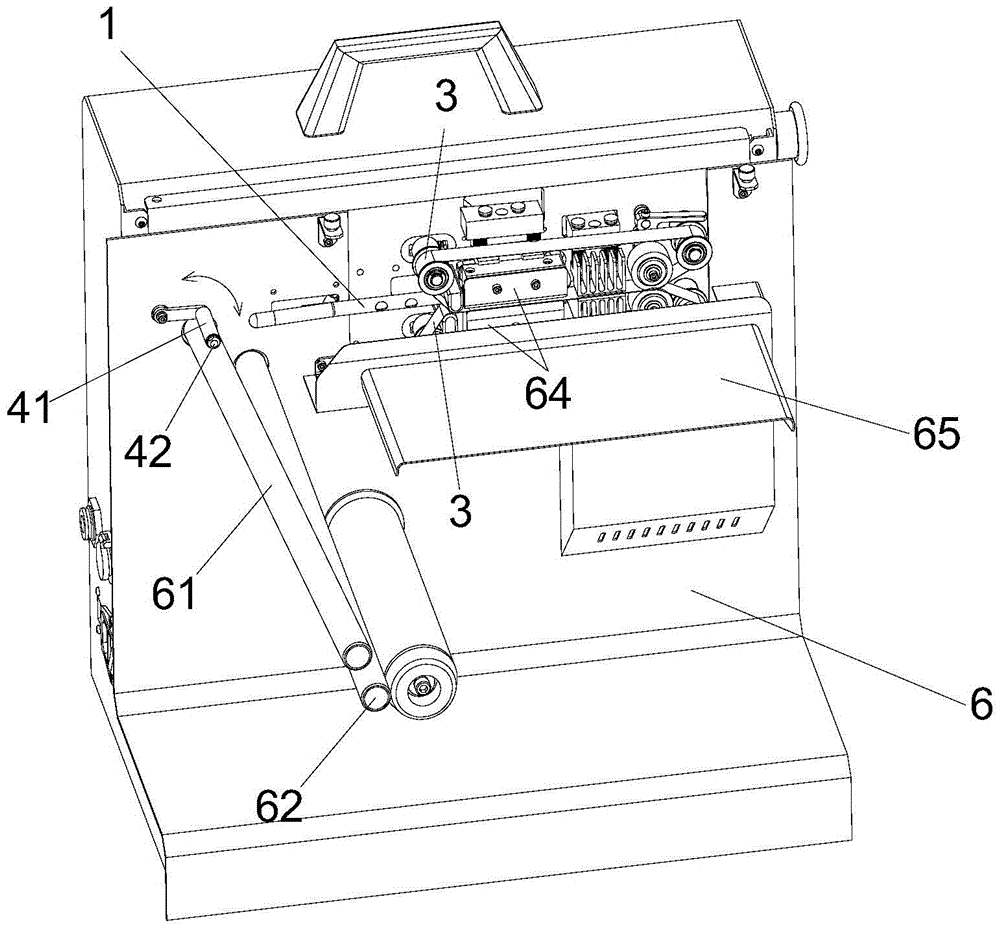

[0022] Figure 1 to Figure 5 Schematically shows the structure of a novel inflatable structure for cushioning an airbag inflator according to an embodiment of the present invention.

[0023] like Figure 1 to Figure 5 As shown, a new inflation structure for cushioning airbag inflators, including inflation guide rod 1, blade 2 and high temperature heating belt 3. In addition, a novel inflation structure for the cushion airbag inflator can also include the blockage wheel module 4 .

[0024] like figure 2 As shown, the interior of the inflatable guide rod 1 is formed with a gas channel 11, the right end of the inflatable guide rod 1 is formed with an air inlet 12 communicating with the gas channel 11, and the middle part of the inflatable guide rod 1 is formed with two gas outlets 13, and the gas outlet 13 communicates with the gas passage 11.

[0025] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com