Battery disassembling machine for movement of pneumatic watch

A technology for disassembling machines and cores, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the time-consuming and labor-intensive problems of manual disassembly, and achieve the effects of saving energy, avoiding short circuits, and fast feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

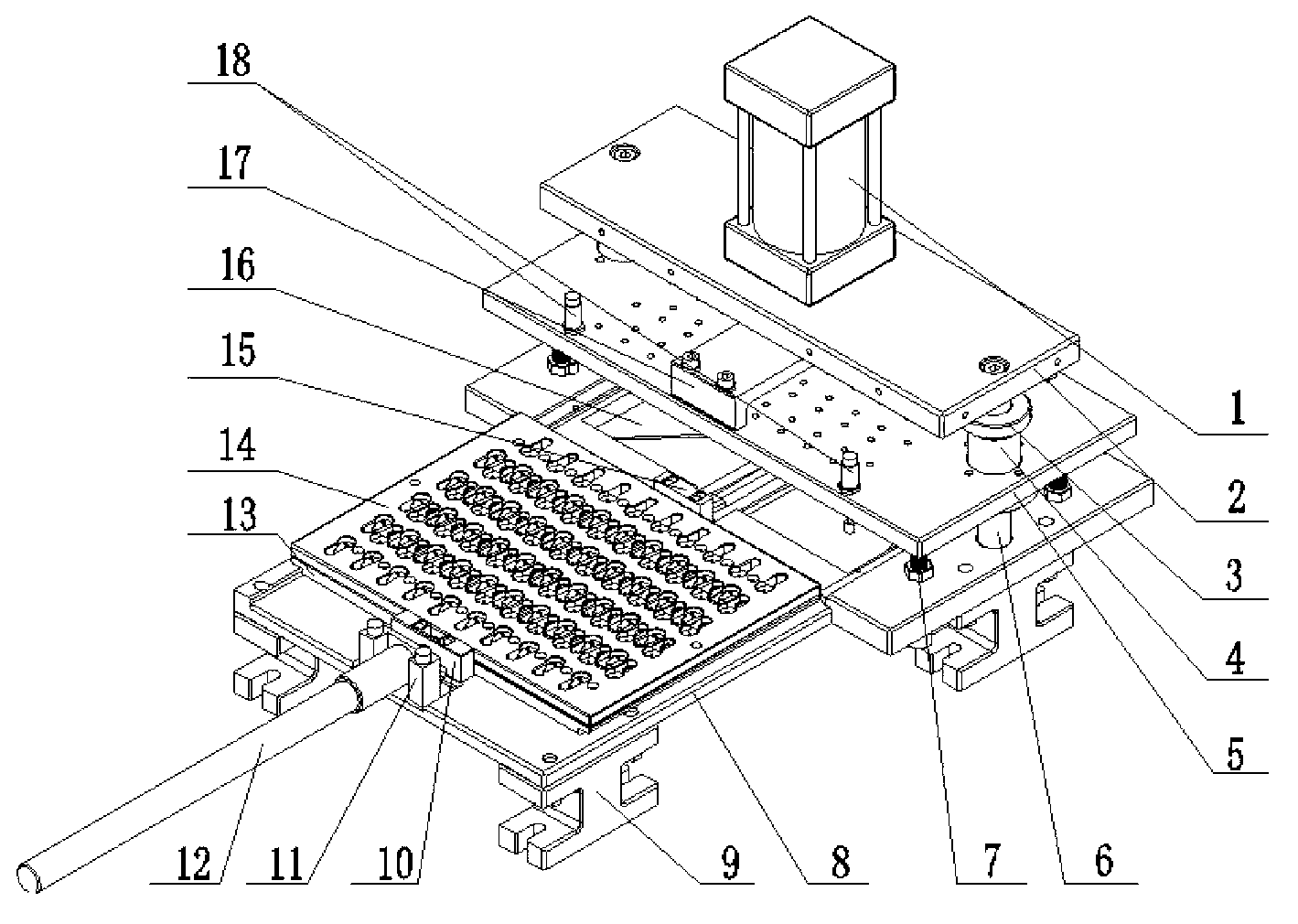

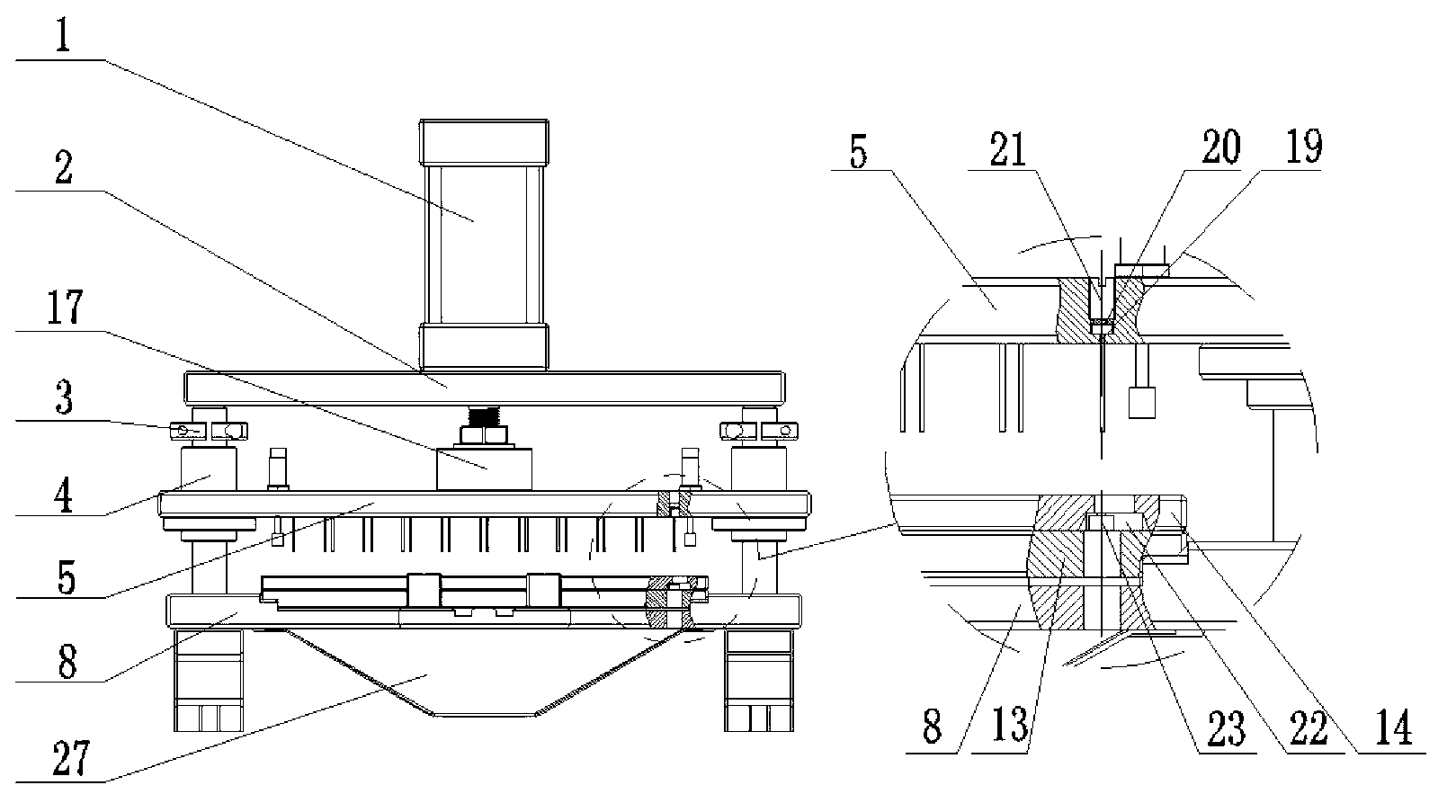

[0017] see Figure 1~5 , The embodiment of the present invention is equipped with a material jacking mechanism, a loading tray, a material feeding and discharging mechanism and a material receiving mechanism.

[0018] The ejecting mechanism is provided with a pressing cylinder 1, a thimble plate 5, a thimble 19, a buffer 18, a guide shaft 6 and a bearing 4; The cylinder connector 17 is connected with the thimble plate 5; the fixed ring 3 is installed on the guide shaft 6, the bearing 4 and the guide shaft 6 are arranged on both sides of the thimble plate 5, and the four limit bolts 7 are installed on the left and right sides of the chute of the bottom plate 8 through nuts On both sides; the bottom plate 8 is fixed on the base 9 to form the workbench of the whole device; the buffer 18 and the thimble 19 are arranged on the thimble plate 5 .

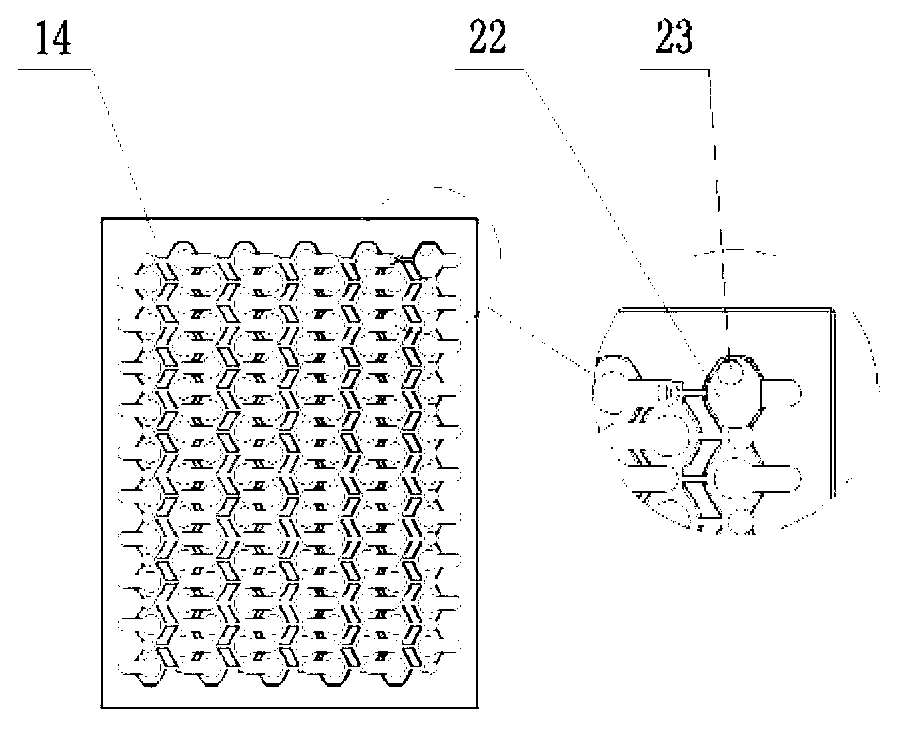

[0019] The loading tray is provided with a loading tray upper plate 14 and a loading tray lower plate 13, and the loading tray lower pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com