Airbag for knee protection

A knee and airbag technology, applied in the field of knee protection airbags, can solve the problems of increased manufacturing hours and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

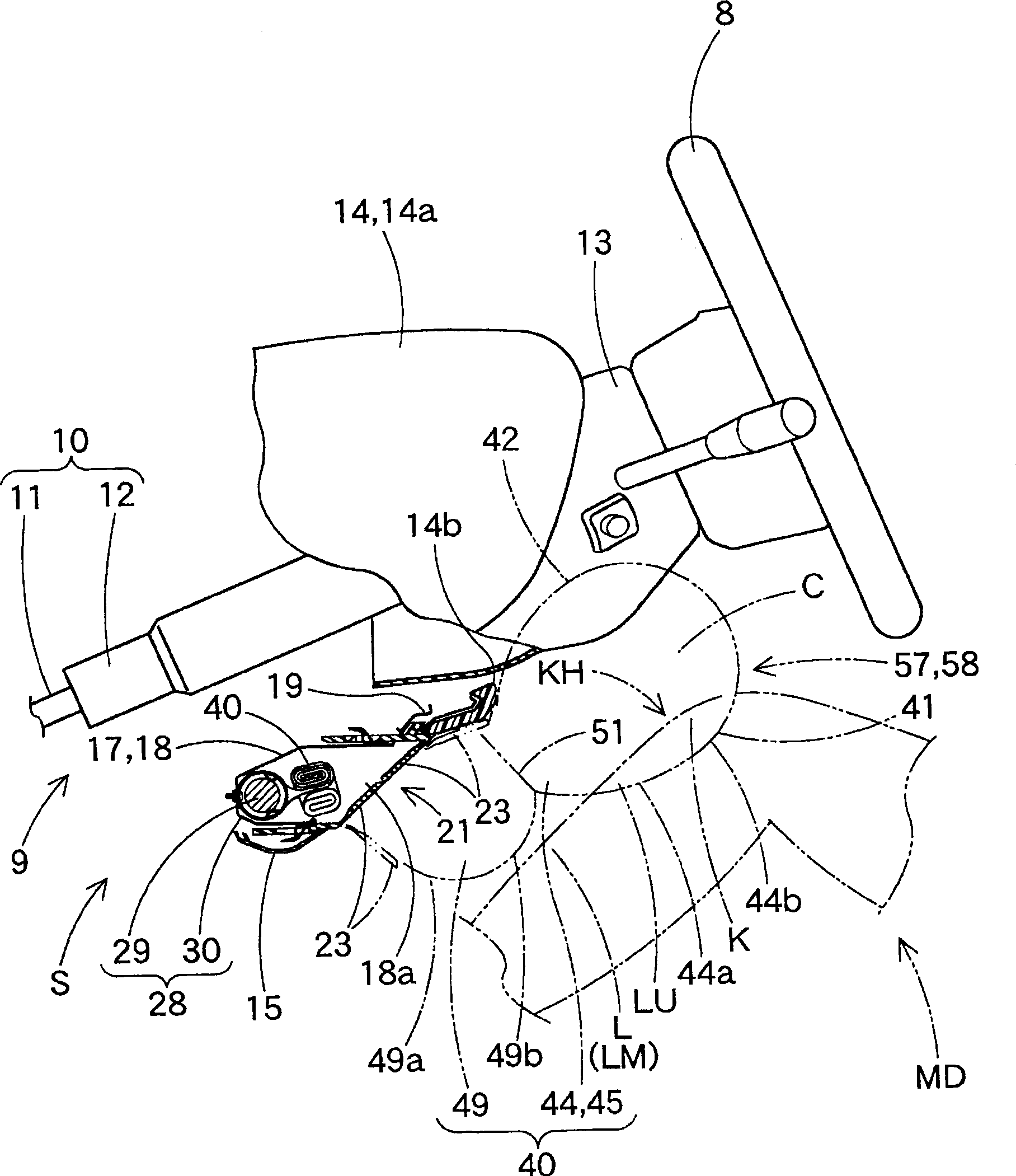

[0053] The knee protection airbag 40 according to the first embodiment is used in the knee protection airbag device S such as figure 1 , 4 As shown, it is disposed on the vehicle front side of the driver MD, that is, below the steering column 9, so that the knee K of the driver MD as a passenger can be protected.

[0054] In addition, the steering column 9 such as figure 1 As shown, there are: a steering column main body 10 connected to the steering wheel 8 ; and a steering column cover 13 arranged to cover the steering column main body 10 below the steering wheel 8 . The steering column main body 10 has a main shaft 11 and a steering column tube 12 covering the periphery of the main shaft 11. The steering column cover 13 has a substantially rectangular tube shape made of synthetic resin, covers the steering column main body 10, and protrudes rearward from an instrument panel 14 (see Figure 4 ).

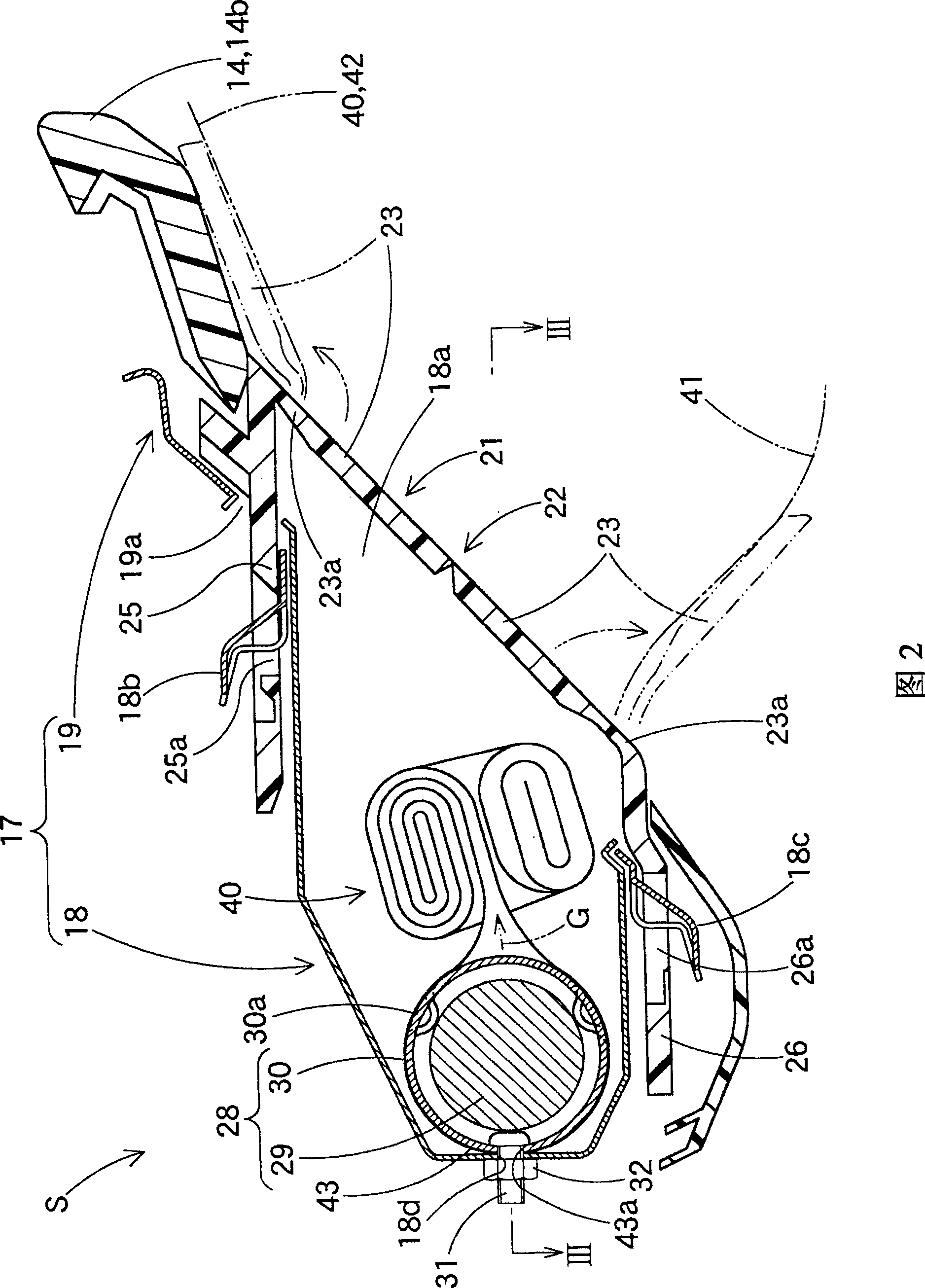

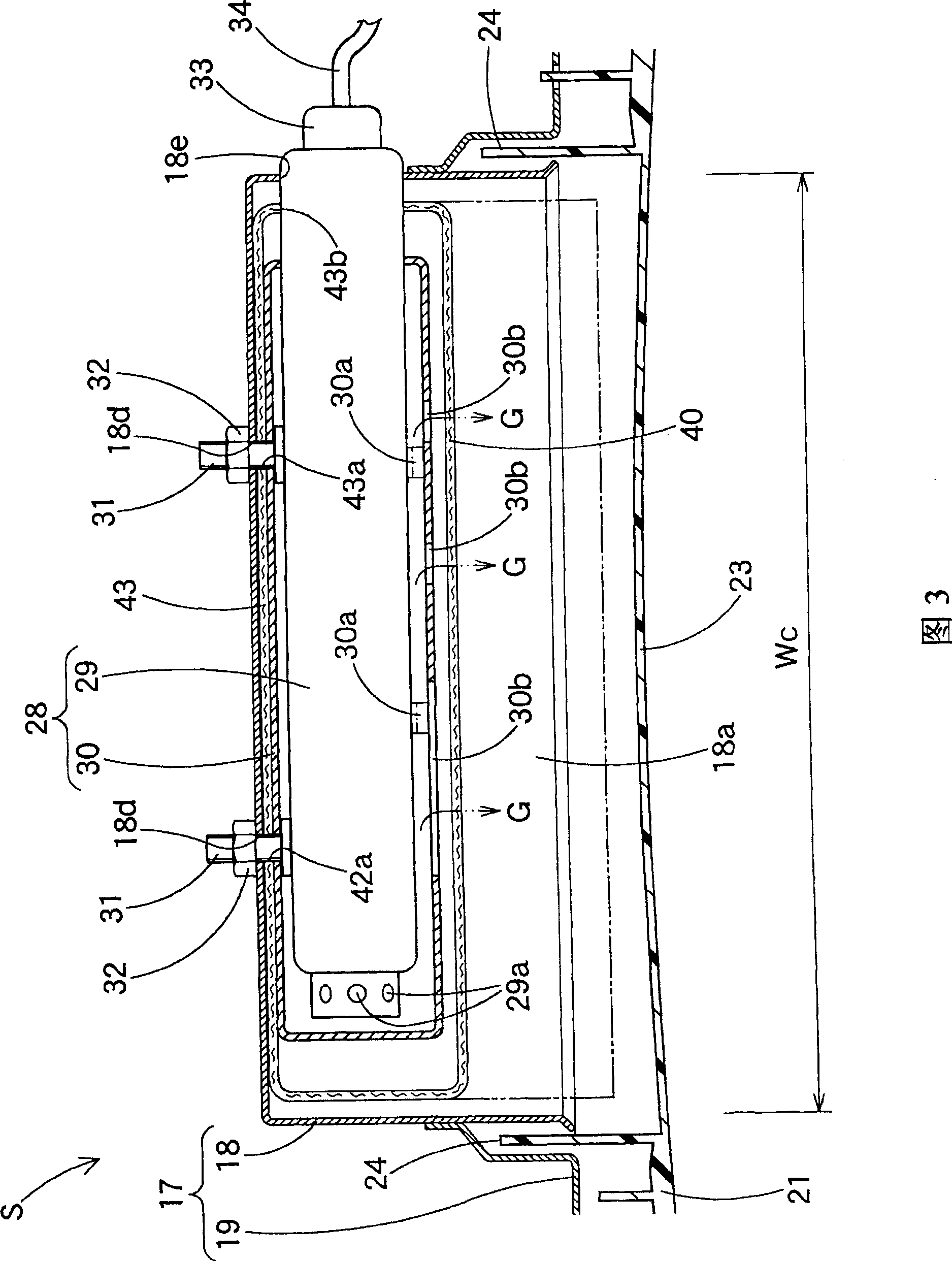

[0055] In addition, the airbag device S for knee protection such as figure ...

Embodiment approach 2

[0089] The airbag 40A of Embodiment 2 is, for example, Figure 14 As shown, similar to Embodiment 1, it is used in the airbag device S for knee protection. This airbag device S for knee protection is the same as that of the first embodiment, except for the airbag 40A, and is constituted by the following components: an inflator 28 which supplies the inflation gas G to the airbag 40A; The airbag 40 and the inflator 28 are opened on the vehicle rear side; and the airbag cover 21 covers the vehicle rear side of the opening 18 a of the casing 17 .

[0090] The airbag 40A of Embodiment 2 differs from the airbag 40 of Embodiment 1 only in that it has a second tether 52 . That is, the airbag 40A as Figure 15 As shown in 17 and 17, similarly to Embodiment 1, it is formed of a woven fabric made of flexible polyester or polyamide threads, and the shape when the expansion is completed is such that the width dimension in the left-right direction on the lower side is reduced. The basebo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com