PCBA test apparatus

A test device and test head technology, applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problems of many mistakes, frequent product replacement, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be further described in detail below.

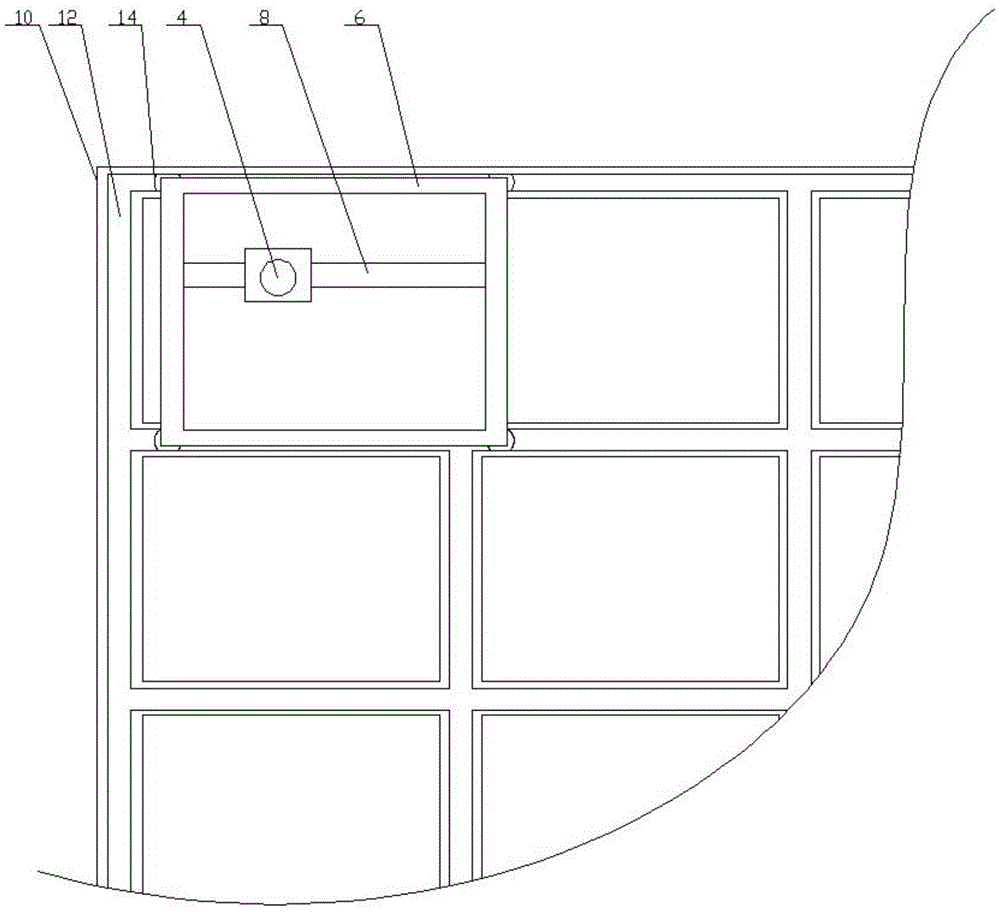

[0017] Such as figure 1 As shown, the present invention includes a workbench, and the workbench is provided with several work positions along the matrix, and is characterized in that it also includes:

[0018] - The test head 4 is arranged directly above the workbench, including a measuring tool for testing the workpiece on the working position and a lifting device for driving the measuring tool to lift;

[0019] - The first track 6 is a rectangular structure, and its horizontal area can completely cover the workpiece to be detected. The first track 6 is provided with two ends that are vertical and are slidably connected to the two parallel sides of the first track 6. Rod 8, the adjustment rod 8 is driven by the first power device to reciprocate along a straight line first track parallel to one of the sides of the first track 6, and the test head 4 is slidably connected to the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com