Fuel cell

A technology of fuel cells and fuel cell stacks, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as changes in gas properties, pressure loss, and problems affecting the reliability of fuel cell systems, and achieve structural simplification and reduction produce a biased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

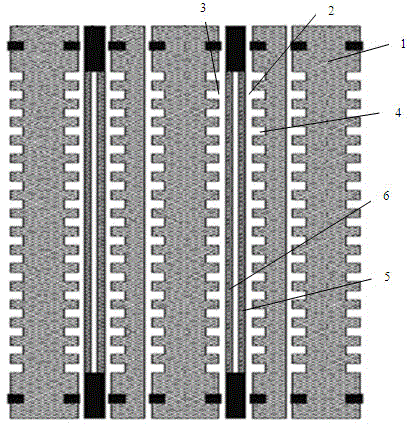

[0016] Such as figure 1 As shown, a fuel cell of the present invention includes a plurality of fuel cell stacks 1; an oxygen gas supply path 2, which is used to supply oxidant gas to the power generation unit; and a hydrogen gas supply path 3, which is used to supply the power generation unit The unit supplies fuel gas; the oxygen supply path 2 is provided with a number of flow channels on the surface of the oxygen flow field plate, and the bottom of the flow channel is spaced along the direction of the flow channel with a number of through holes vertically penetrating the oxygen flow field plate. The oxygen pole plate 5 of the path 2 is a microporous water-oxygen humidification pole plate; the hydrogen gas supply path 3 is provided with a water flow channel and a hydrogen flow channel on both sides of the water-hydrogen bipolar plate, and its setting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com