PTC heater heat sink strip

A heater and heat dissipation strip technology, applied in ohmic resistance heating parts and other directions, can solve problems such as affecting the quality of air conditioners, unsatisfactory heat dissipation effect, easy bending damage, etc., and achieves novel structure, good heat dissipation effect and high safety factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

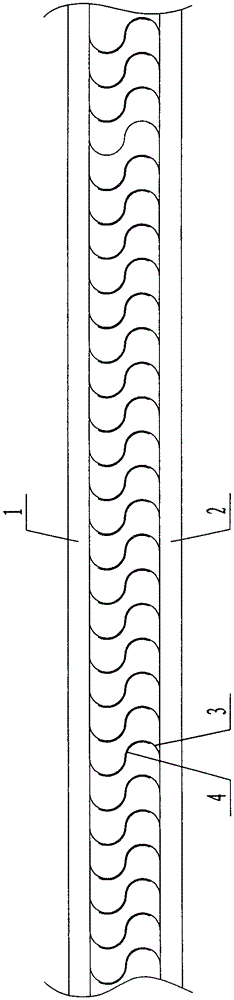

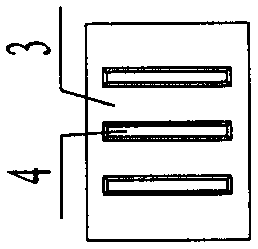

[0011] Such as figure 1 , figure 2 As shown, the heat dissipation strip of the PTC heater includes: an upper fixing piece 1, a lower fixing piece 2 connected with the heating core of the PTC heater, and several S-shaped fixing pieces are evenly arranged between the upper fixing piece 1 and the lower fixing piece 2 The heat sink 3 is uniformly provided with several trapezoidal reinforcing rib protrusions 4 on the S-shaped heat sink 3 .

[0012] Such as figure 1 , figure 2 As shown, in this example, three trapezoidal rib protrusions 4 are uniformly arranged on the S-shaped heat sink 3 .

[0013] The heat dissipation strip of the above-mentioned PTC heater has a novel structure. The heat sink adopts an S-shaped curved surface structure instead of the original straight and inclined surface structure, which increases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com