Optical film with reverse wavelength dispersion and display device including same

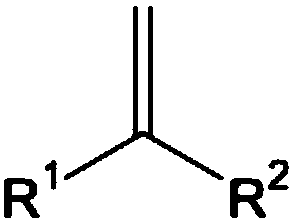

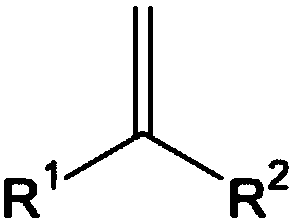

一种光学膜、化学式的技术,应用在光学膜领域,能够解决丧失液晶特性、不能诱导反向波长色散等问题,达到薄厚度、优良反向波长色散的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

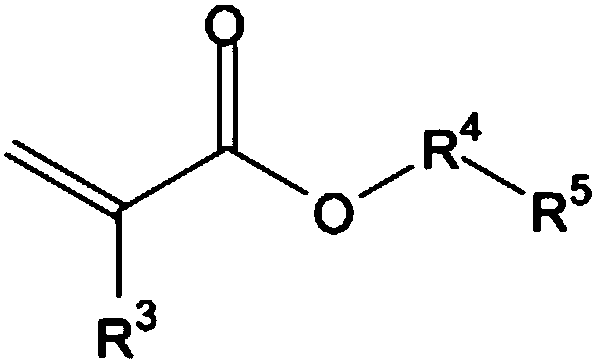

[0085] In the preparation method of another embodiment of the present invention, the step of preparing the copolymer can be carried out by the following process: at a temperature of 20 to 120° C., while stirring, polymerizing the compound containing 80-99.99% by weight of the chemical formula 1 The compound and the monomer mixture of 0.01-20% by weight of the acrylate-based compound, the organic solvent and the polymerization initiator are combined for 1 to 24 hours.

[0086] Here, organic solvents and polymerization initiators commonly used in the art to which the present invention pertains may be used in the polymerization reaction, and their types are not particularly limited.

[0087] According to one embodiment of the present invention, the organic solvent may include: aromatic hydrocarbons, such as toluene, xylene, etc.; esters, such as ethyl acetate, butyl acetate, ethylene glycol monomethyl ether acetate, ethylene glycol Monoethyl ether acetate, propylene glycol monome...

Embodiment 1

[0098] A monomer mixture comprising about 90% by weight of N-vinylcarbazole and about 10% by weight of acrylic acid, about 200 parts by weight of solvent toluene based on 100 parts by weight of the monomer mixture, and 0.05 parts by weight of a polymerization initiator Azobisisobutyronitrile was added to the reactor, and then at about 70° C., polymerization was carried out for 18 h while stirring, to obtain a compound containing a copolymer (having a weight average molecular weight of about 120,000 and a glass transition temperature of about 197° C.). solution.

[0099] The solution was cast on a cycloolefin polymer film (having a thickness of about 100 μm), then dried, and stretched (about twice) in the longitudinal direction to obtain an optical film having a thickness of about 67 μm (including the substrate).

[0100] Measure the retardation value of the optical film, the result is Δn (450nm) =0.88, Δn (550nm) = 1.00 and Δn (650nm) =1.07, confirming that the optical film...

Embodiment 2

[0102]In the same manner as in Example 1, except for using a monomer mixture containing about 95% by weight of N-vinylcarbazole and about 5% by weight of acrylic acid, a copolymer (having a weight average molecular weight of about 130,000 and about 202 °C glass transition temperature) solution. An optical film having a thickness of about 65 μm was obtained by performing solution casting and stretching processes in the same manner as in Example 1 except for using the above solution.

[0103] Measure the retardation value of the optical film, the result is Δn (450nm) =0.88, Δn (550nm) = 1.00 and Δn (650nm) =1.06, confirming that the optical film satisfies the conditions according to Formula I and Formula II.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com