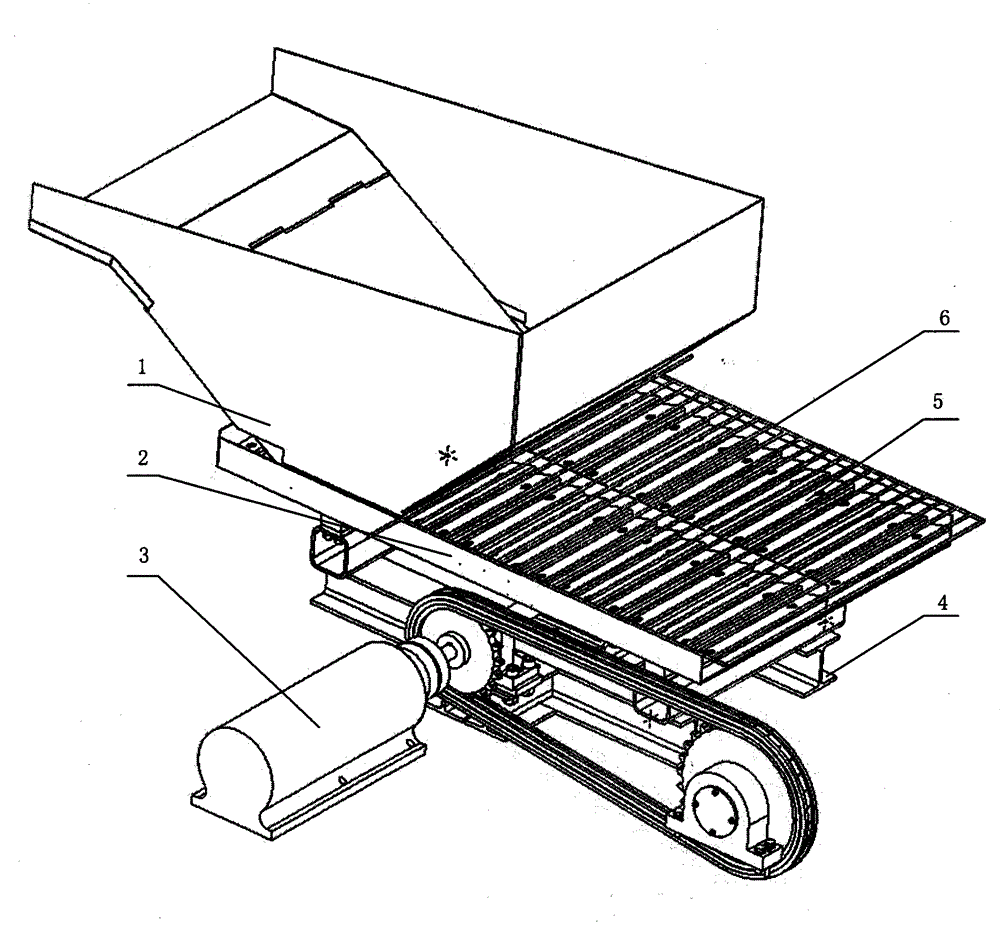

Reciprocating type maize sequencing charging mechanism of maize sheller

A peeling machine and reciprocating technology, applied in agricultural machinery and tools, conveyor objects, threshing equipment, etc., can solve the problems of time-consuming and laborious, unable to guarantee the processing time of fresh corn, poor adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

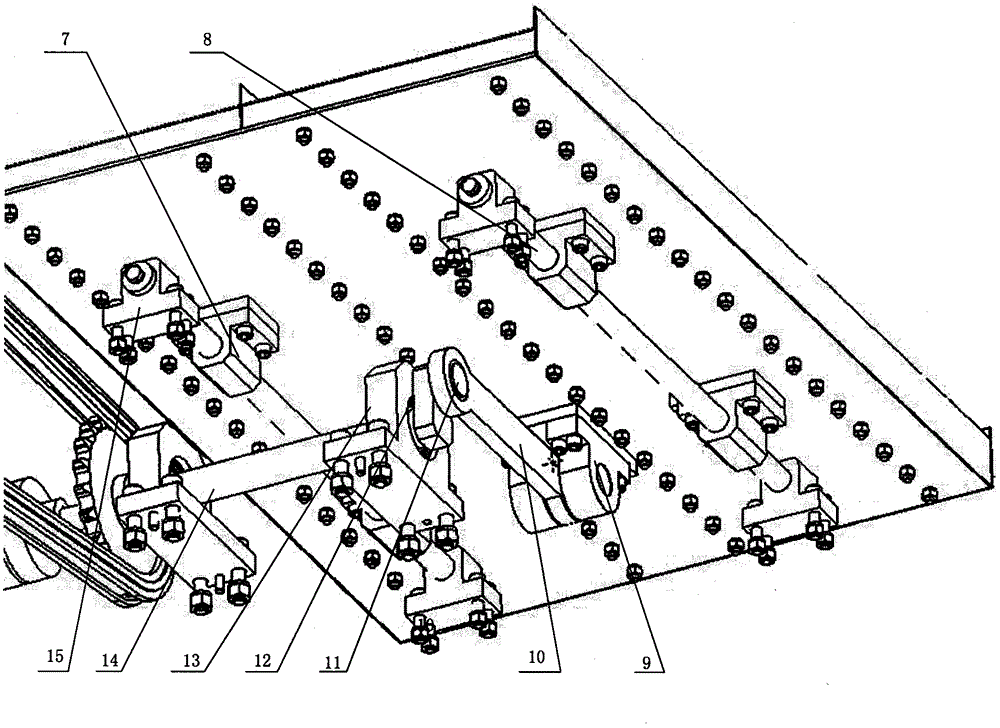

[0010] The specific implementation is as attached figure 1 , the corn is put into the hopper 1 manually, the corn falls on the sorting plate 5 through the hopper 1, the outer ring of the bearing 12 is matched with the bearing seat 13, the eccentric shaft 14 is matched with the inner ring of the bearing 12, and the motor drives the eccentric shaft 14 to rotate. The eccentric shaft 14, the connecting piece 10, the base 11 together with the pin shaft form a slider crank mechanism, and the eccentric shaft drives the rotation of 14 to make the connecting piece 10 swing back and forth, so that the connecting piece 10 drives the frame 9 to move left and right. 10 is fixed with the tray 2, and the tray 2 is fixed with the sorting plate 5, so that the tray 2 and the sorting plate 3 move left and right together. In order to make the tray 2 slide stably, the present invention adds four stable 15, every two stabilizers 15 are connected with a guide rod 8, and two sliders 7 are added on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com