Internally opposite rotation type stirring electric pressure cooker internal opposite-rotation type

An electric pressure cooker and inner pot technology, applied in heating devices, cooking utensils, household utensils, etc., can solve the problems of poor taste, poor electric heating of electric pressure cookers, and high heating intensity, and achieve good internal stirring effect and energy consumption. less, good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

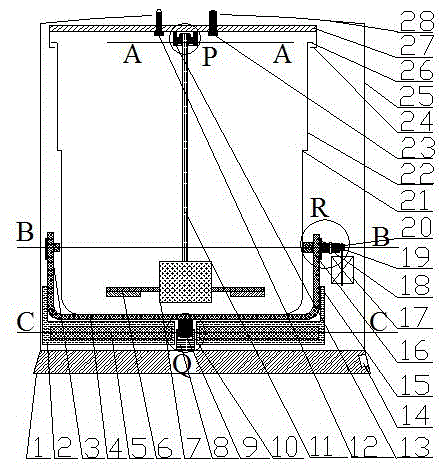

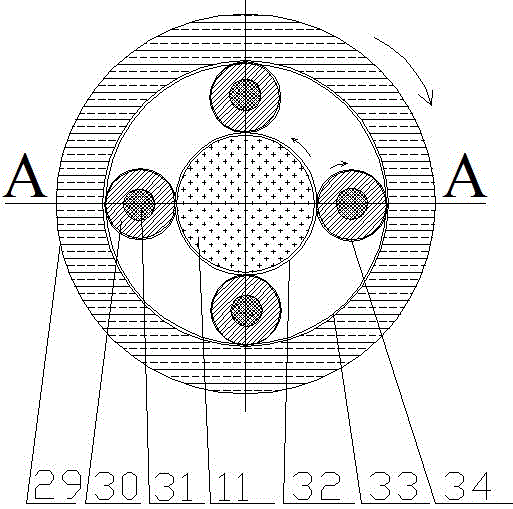

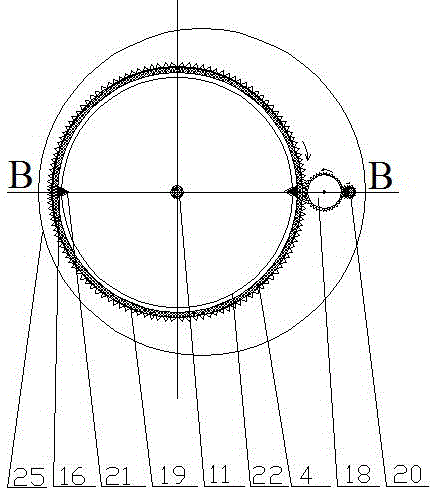

[0021] exist figure 1 In the embodiment shown in -7: the inner reverse stirring electric pressure cooker includes a base 1, a heating plate 5, a rotating holder 4, an inner tank 22, and a motor 17; it is characterized in that: the heating plate 5 is annular, and the heating plate 5 A layer of heating plate cover 2 is wrapped outside. The heating plate cover 2 is in the shape of a cup. Above, a rotating support 4 is installed in the upper side gap of the heating plate cover 2, and the rotating support 4 is also a cup shape. A rotating shaft 9 is fixedly installed in the center of the bottom of the rotating supporting 4, and the lower end of the rotating shaft 9 is supported by a bearing. 10 is connected with the supporting shaft 8, and the supporting shaft 8 is fixedly installed in the center of the upper side of the base 1, so that the rotating shaft 9 can support the rotating bracket 4 and the rotating bracket 4 can rotate around the supporting shaft 8, the rotating shaft 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com