Dust collector sucking head and dust collector containing same

A vacuum cleaner and suction duct technology, applied in the directions of vacuum cleaners, suction nozzles, cleaning equipment, etc., can solve the problems of difficult cleaning and unsatisfactory dust removal effect, and achieve the effect of improving cleaning effect and saving cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, specific embodiments of the present invention will be described in detail. However, the present invention is not limited to the following description, and those skilled in the art can make various improvements and modifications on this basis.

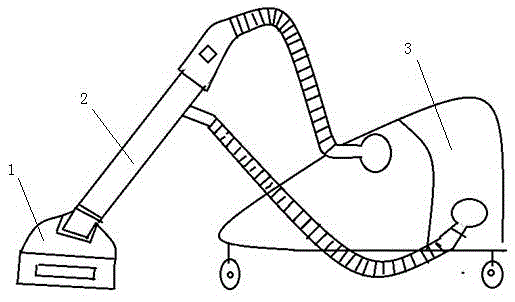

[0024] Refer to attached figure 1 As shown, the vacuum cleaner of the present invention includes a suction head 1 , a suction rod 2 and a host 3 connected in sequence.

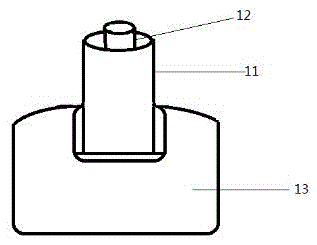

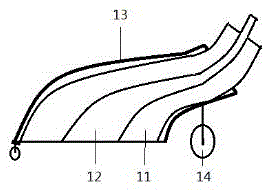

[0025] Refer to attached Figures 2 to 4 As shown, the suction head 1 of the vacuum cleaner of the present invention includes: a suction pipe 11 , an air outlet pipe 12 and an outer casing 13 arranged on the outermost layer. Wherein the air outlet pipe 12 is located inside the air suction pipe 11 , preferably, the air outlet pipe 12 is located at the inner center of the air suction pipe 11 . The air outlet pipe 12 is fixed in the air suction pipe 11 through multiple mediastinums or other conventional methods, and the shapes of the air outlet pipe 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com