Mechanical hand clamp

A manipulator and fixture technology, applied in manipulators, chucks, manufacturing tools, etc., can solve the problems of low production efficiency, high positioning accuracy requirements, and high failure rate in the processing process, so as to improve work efficiency, continue to work efficiently, and reduce labor. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

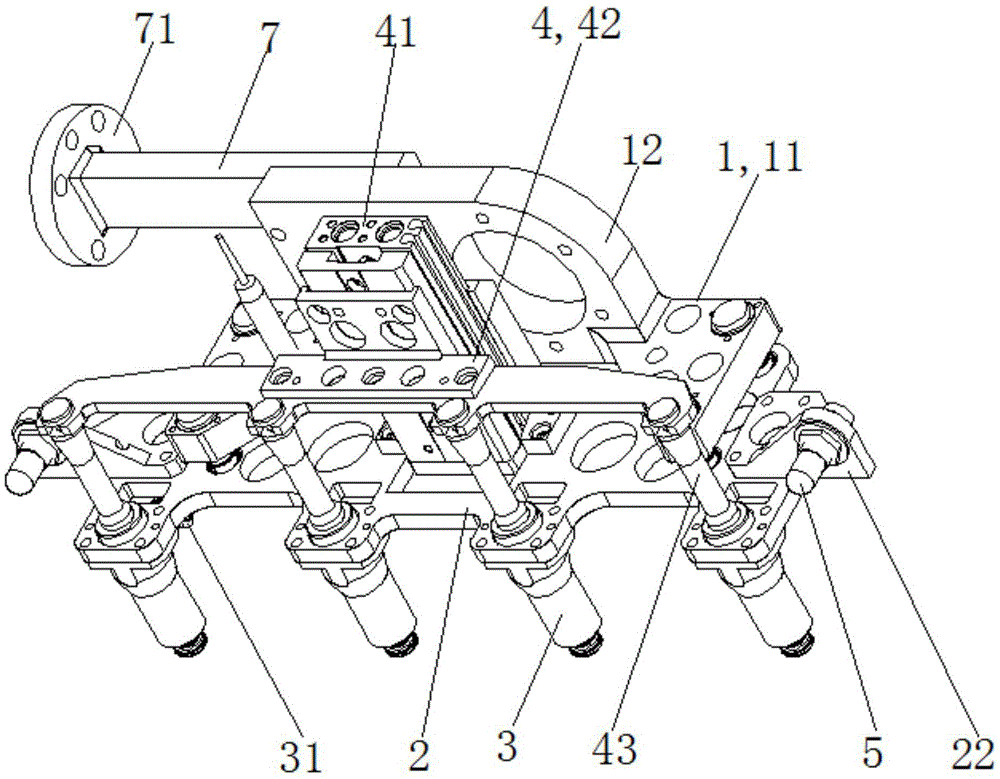

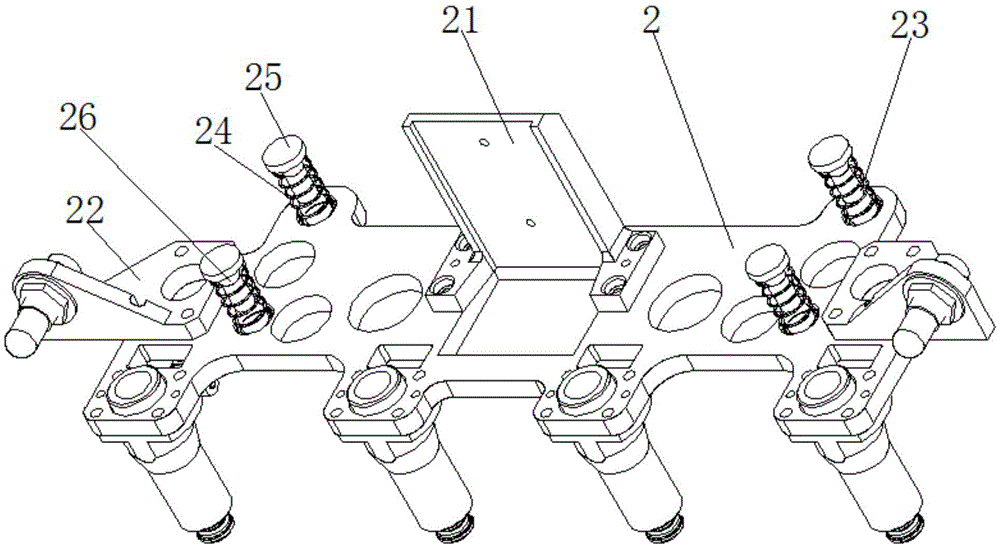

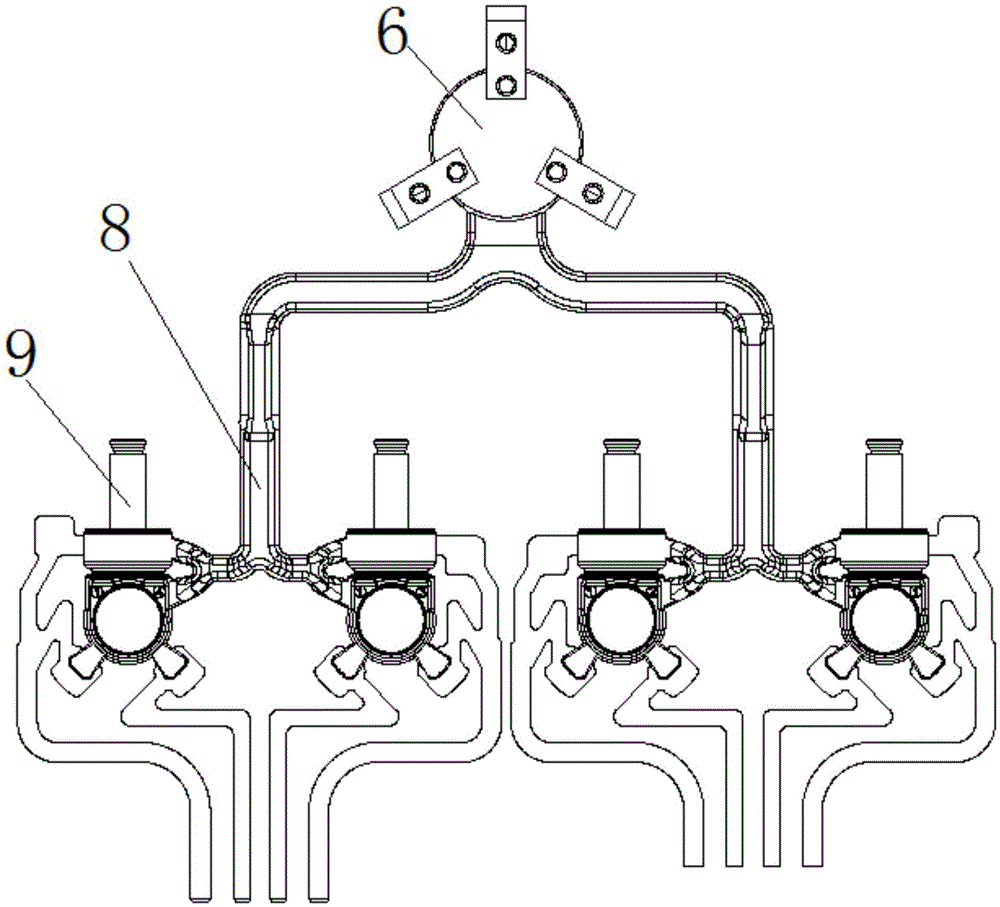

[0017] Attached below Figure 1 to Figure 3 The present invention is set forth in detail:

[0018] A gripper for a manipulator, which includes a connecting arm 7 , a connecting seat 1 , a floating seat 2 , a pick-up bucket 3 , an assembly assembly 4 , a positioning sensor 5 and an unloading assembly 6 .

[0019] The left end of the connecting arm 7 is provided with a flange 71 connected with the manipulator, and the right end of the connecting arm 7 is fixedly connected or integrally formed with the connecting seat 1 .

[0020] The connecting base 1 includes a bottom plate 11 and a rear side plate 12 , the bottom plate 11 and the rear side plate 12 are integrally formed or fixedly connected, and the four corners of the bottom plate 11 are provided with cylindrical through holes 13 .

[0021] The floating seat 2 is arranged under the connecting seat 1, and the middle part of the floating seat 2 is provided with a mounting seat 21 for installing a lifting mechanism. The left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com