A slitting machine with horizontal and vertical bidirectional cutting functions

A cutting machine and slitting machine technology, applied in metal processing and other directions, can solve problems such as a large number of manual operations, non-standard plate size, and increased plate errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

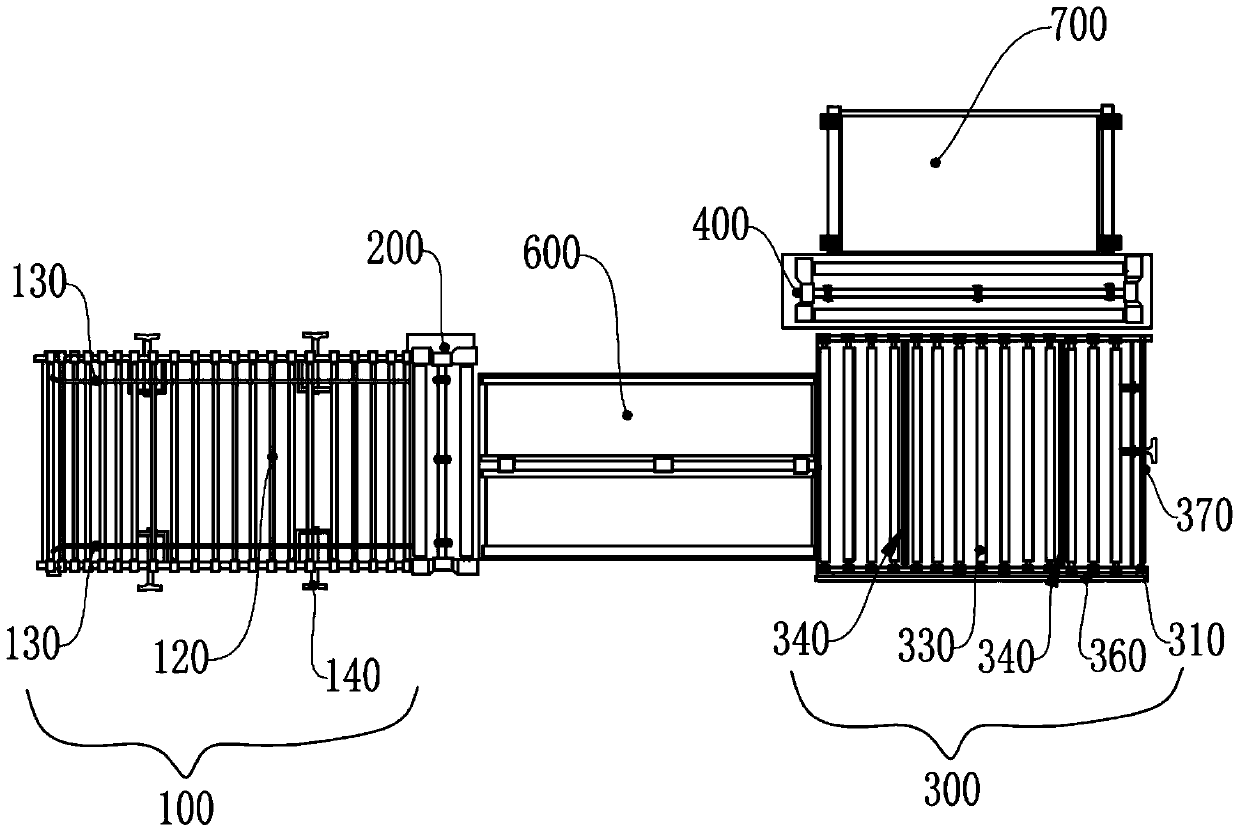

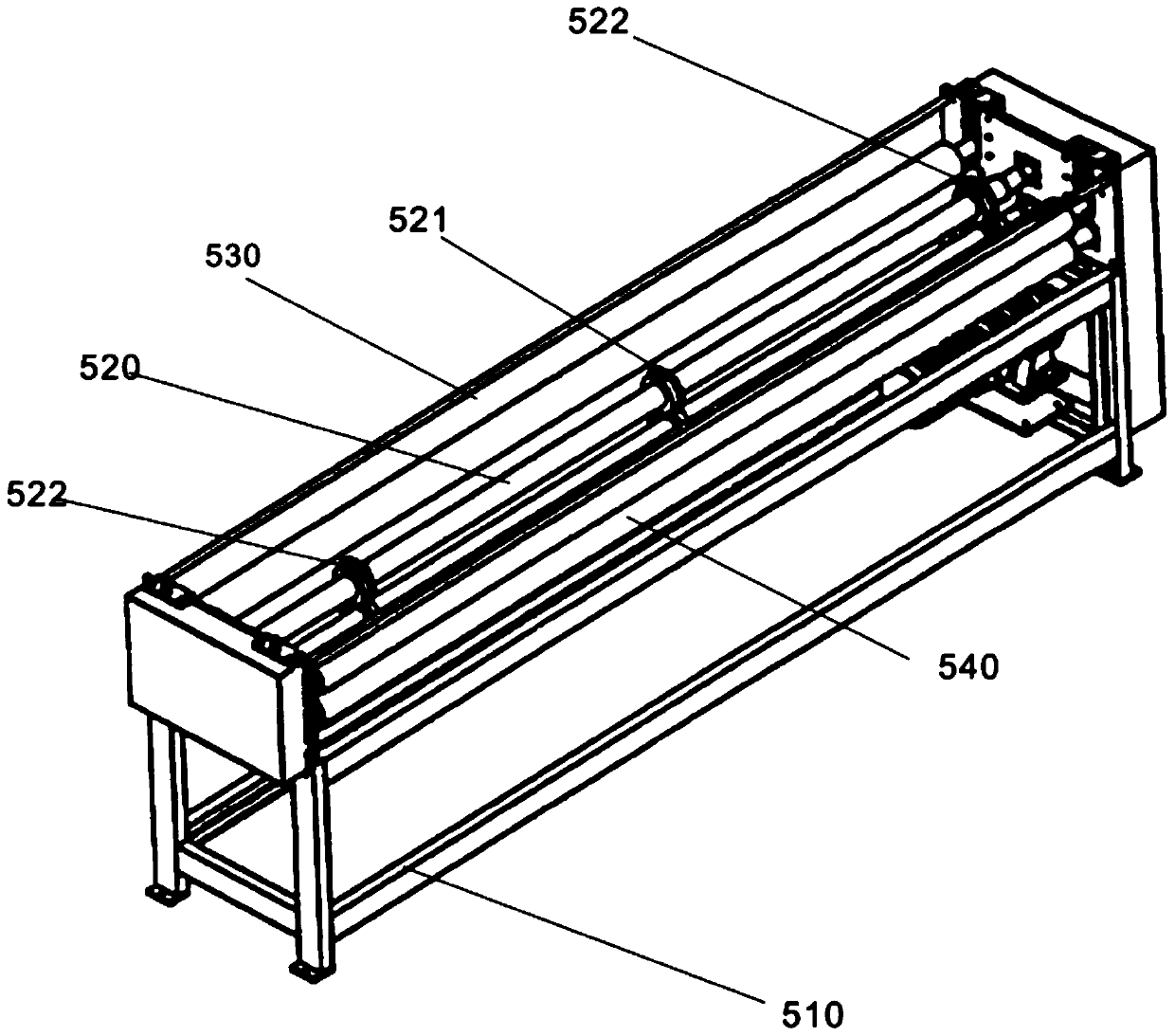

[0025] Such as Figure 1-3 As shown, a slitting machine with horizontal and vertical bidirectional cutting functions includes a horizontal transport device 100, a horizontal cutting machine 200, a turning transport device 300 and a longitudinal cutting machine 400; structure and the longitudinal push plate mechanism, the conveying direction of the transverse conveying structure and the push plate direction of the longitudinal push plate mechanism are perpendicular to each other; the feed port of the transverse cutting machine 200 is docked with the discharge end of the transverse transport device The discharge port of the transverse cutting machine 200 is docked with the feed end of the diverting transport device 300 ;

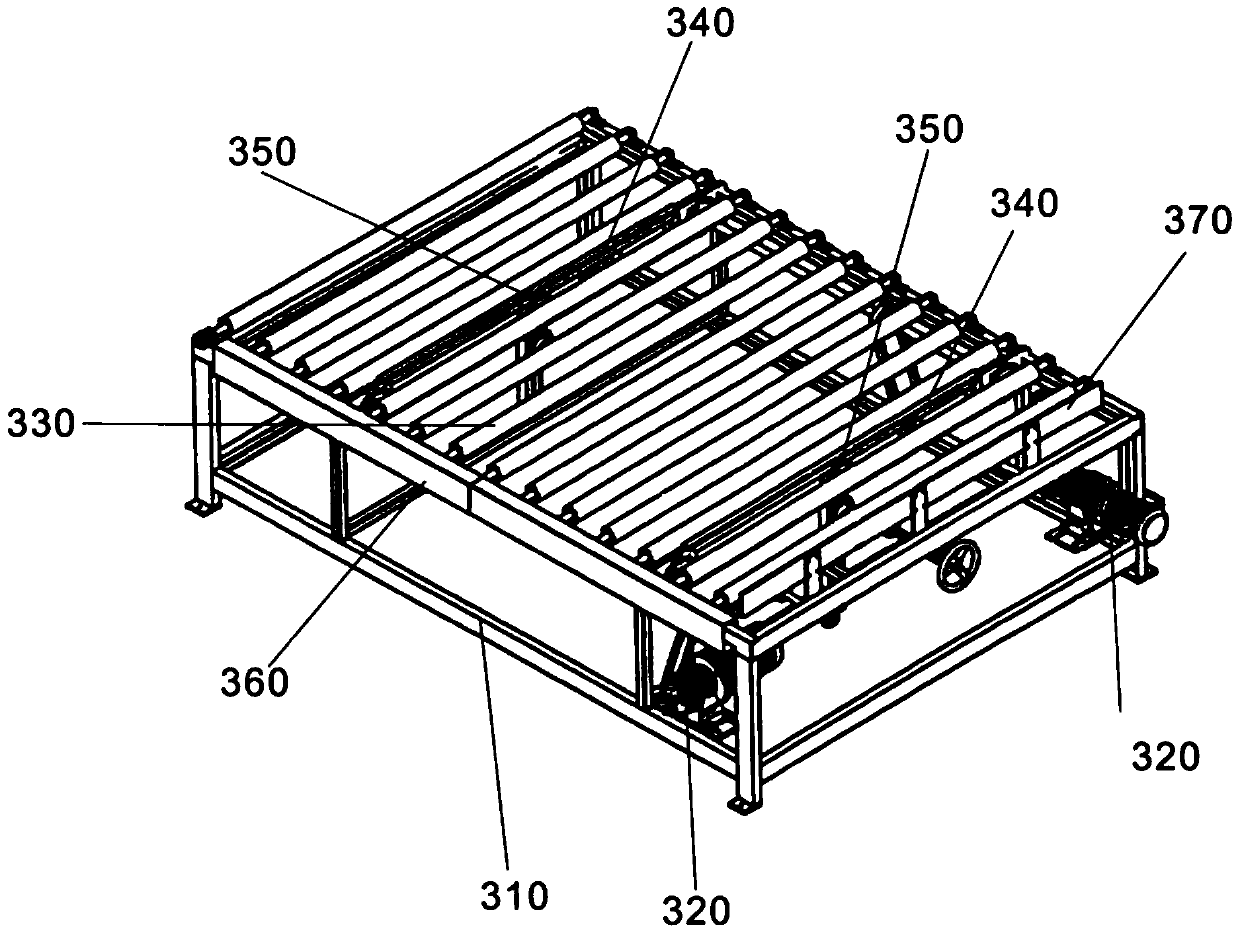

[0026] The steering transport device 300 also includes: a frame 310 and two se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com