Vacuum auxiliary exhausting type segmental mold

A flexible mold and vacuum-assisted technology, which is applied in the field of tire manufacturing, can solve the problems of unclear tire tread edges, large tire rubber edges, and open tire joints, etc., to achieve the effect of less rubber wool and clear tread edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Those skilled in the art will be more aware of the above and other objects, advantages and features of the present invention according to the following detailed description of specific embodiments of the present invention in conjunction with the accompanying drawings.

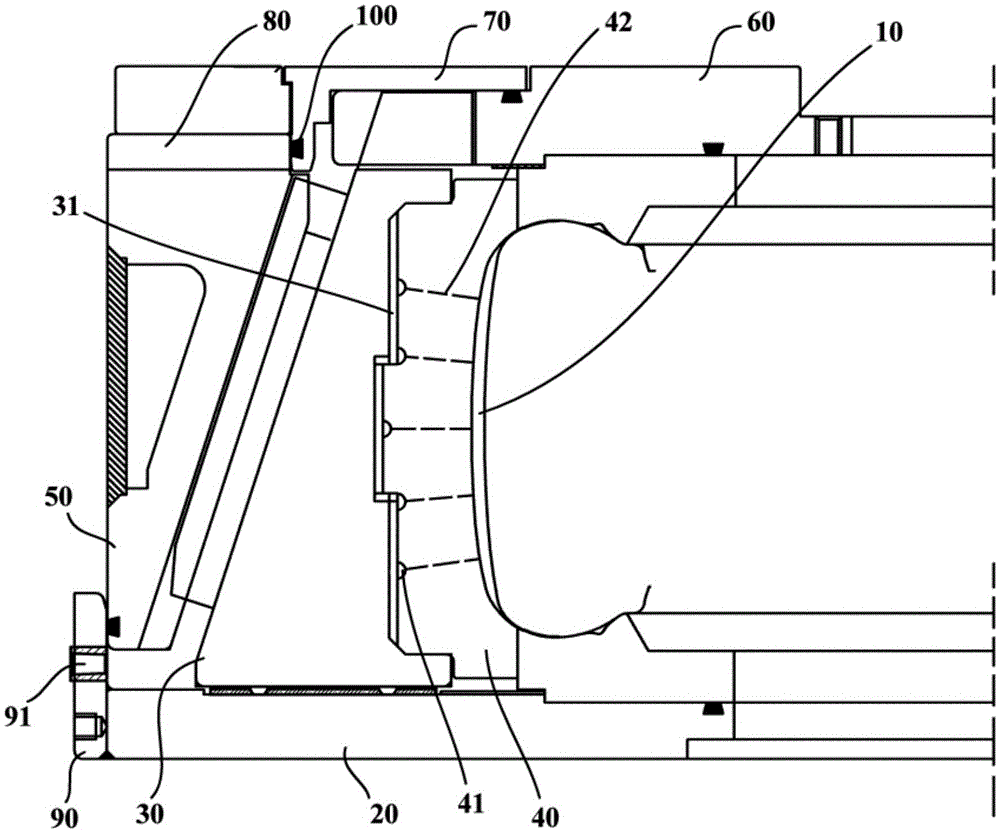

[0026] figure 1 It is a schematic partial structure diagram of a vacuum-assisted exhaust type movable mold according to an embodiment of the present invention. Such as figure 1 As shown, the embodiment of the present invention provides a vacuum-assisted venting type movable mold, which can be used in tire manufacturing. The vacuum assisted exhaust type movable mold can include a bottom plate 20 , a bow seat 30 , a pattern block 40 , a middle sleeve 50 , an upper cover 60 , an upper sealing ring 70 , a middle sealing ring 80 , a plurality of sealing rings 100 , and a cavity 10 . The bow seat 30 and the pattern block 40 are disposed on the bottom plate 20 . The middle sleeve 50 is installed on the bow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com