Hot pressing mold of conical cover

A technology of hot-press forming and conical hood, which is applied in the field of hot-press forming molds for conical hoods, can solve the problems of low heating efficiency and reduced precision of electric heating tubes, and achieve stable and reliable product quality, improved positioning accuracy and structural strength, Effect of heating efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present application solve the technical problems in the prior art that the heating efficiency of the electric heating tube is low and the positioning method of the guide post sleeve leads to a decrease in precision by providing a hot-press forming mold for the conical cover.

[0031] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

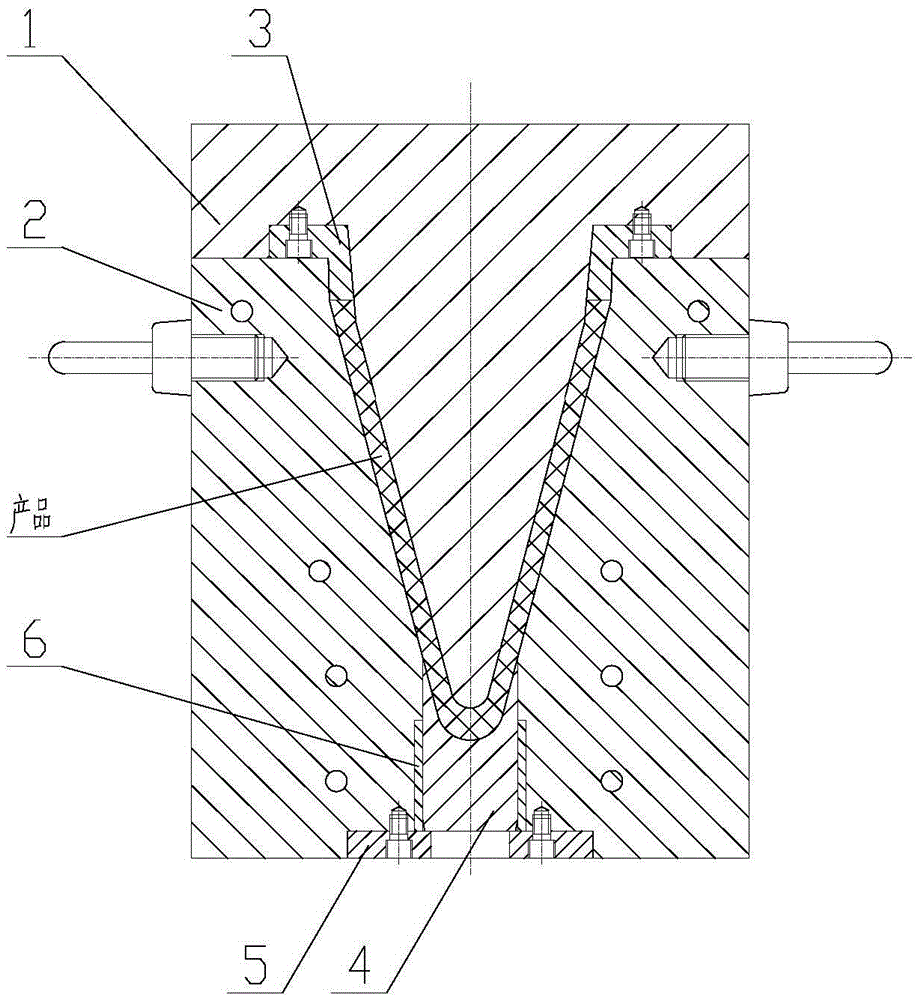

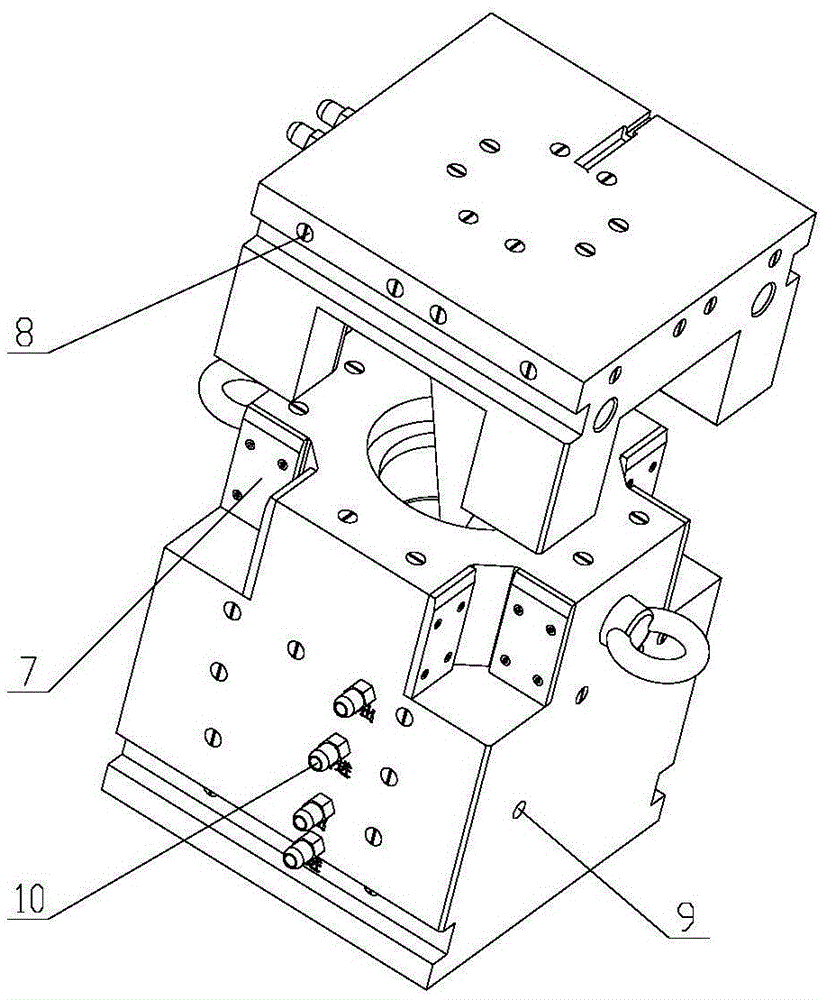

[0032] A kind of thermocompression forming mold of conical cover, described thermocompression forming mold comprises:

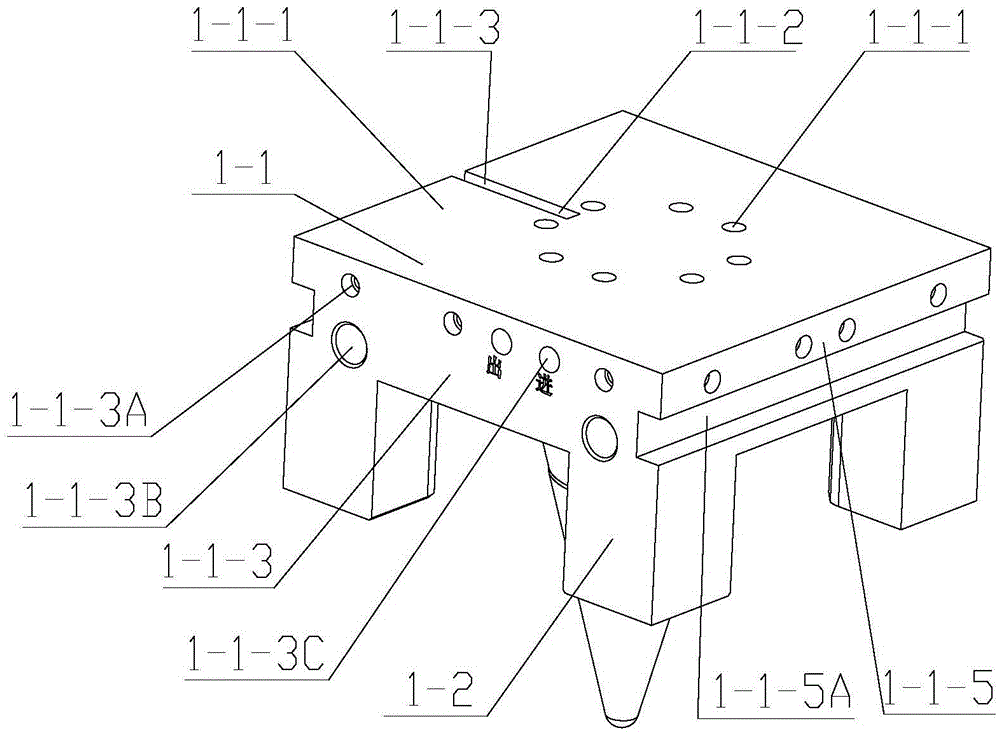

[0033] The upper mold includes a cone, an upper mold oil circuit system and a plurality of positioning blocks located around the cone, and a plurality of chutes are opened in the cone, and the upper mold oil circuit system is arranged in the chute;

[0034] The lower mold is provided with an inner cavity, and the inner cavity includes a feeding cavity matched with the shape of the cone and a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com