The cloth roll conveying device of the multi -layer layer

A conveying device and spreading machine technology, which is used in transportation and packaging, spreading thin soft materials, winding strips, etc. Conveying efficiency of cloth rolls, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

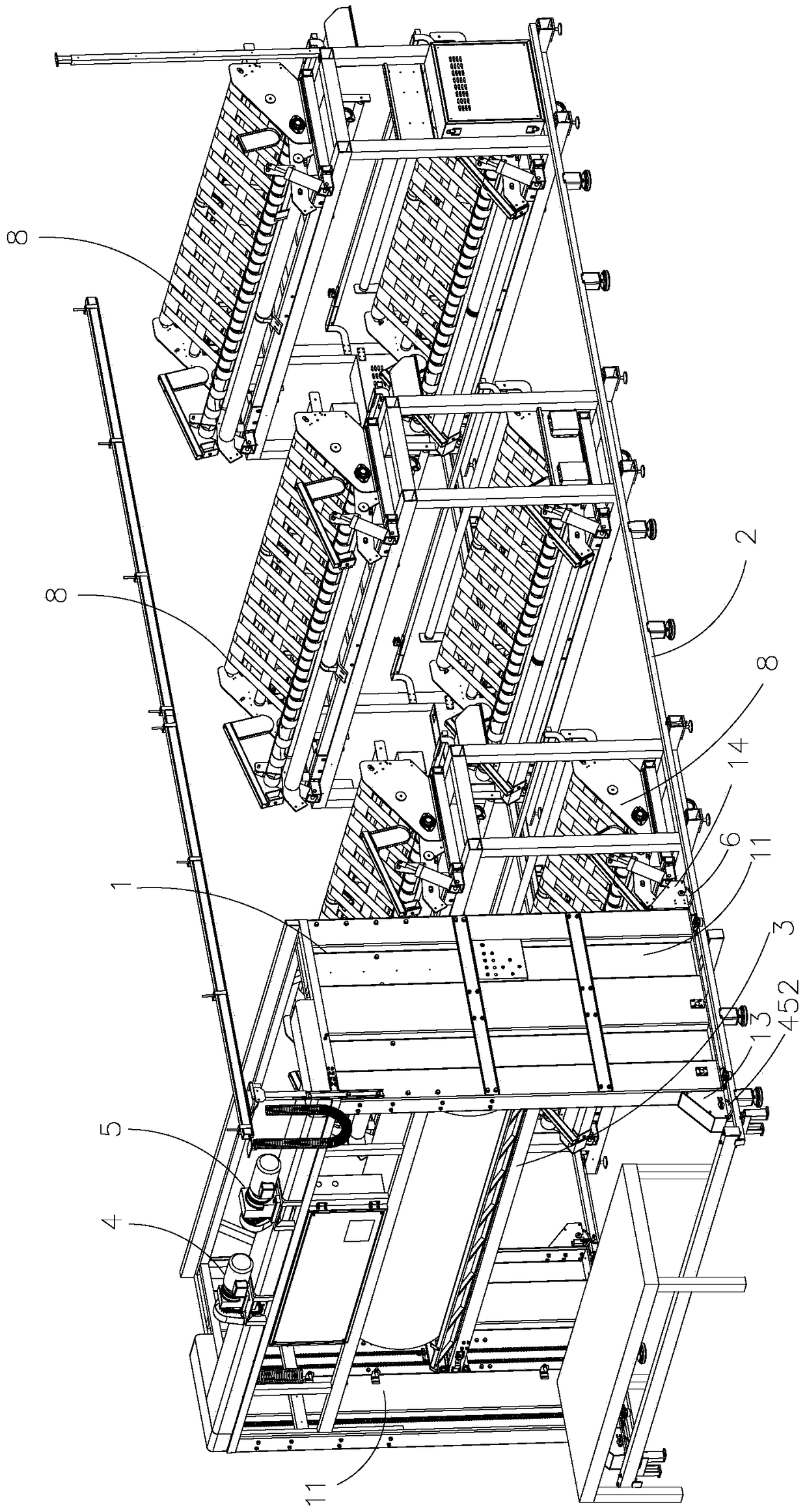

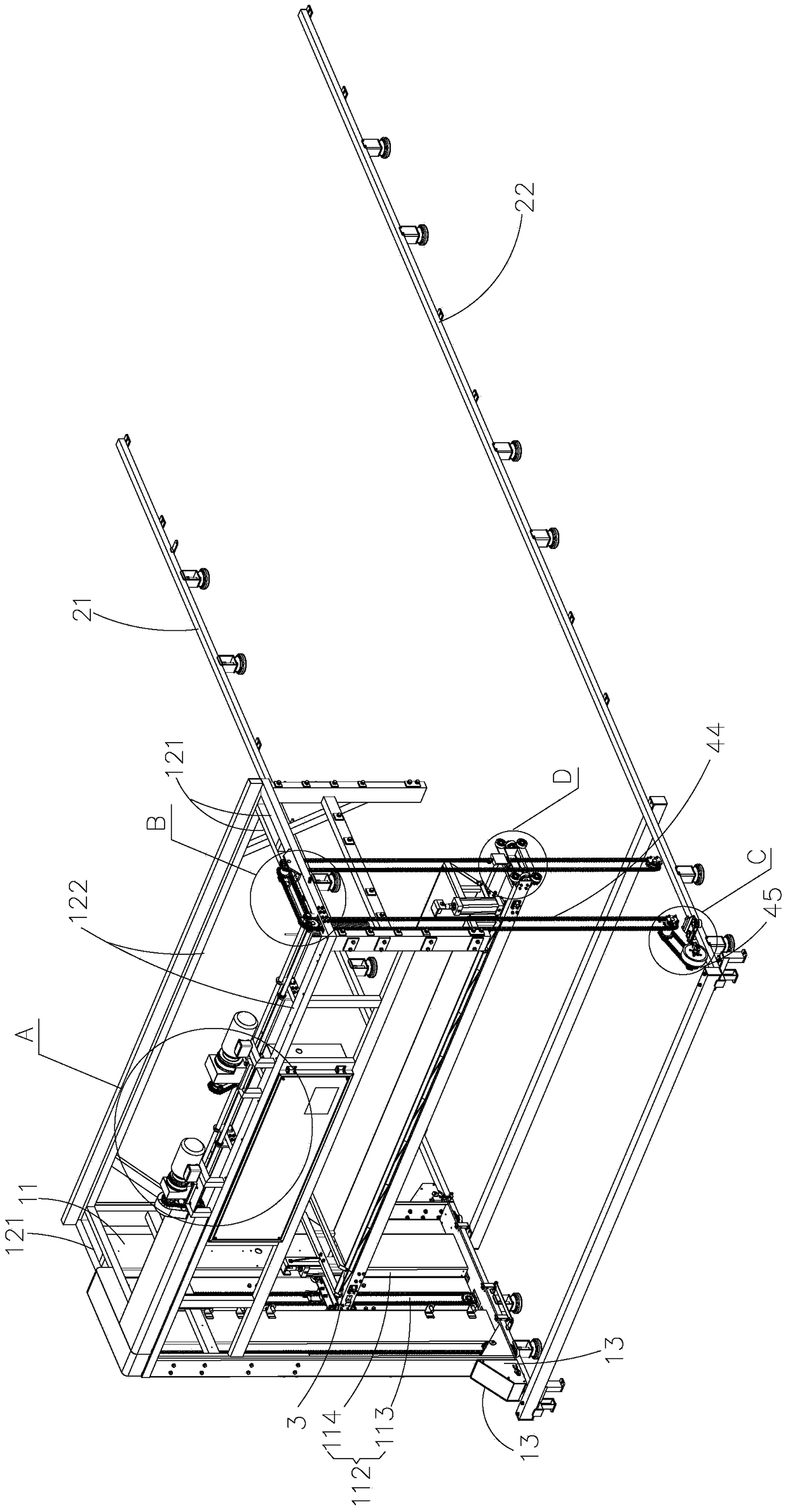

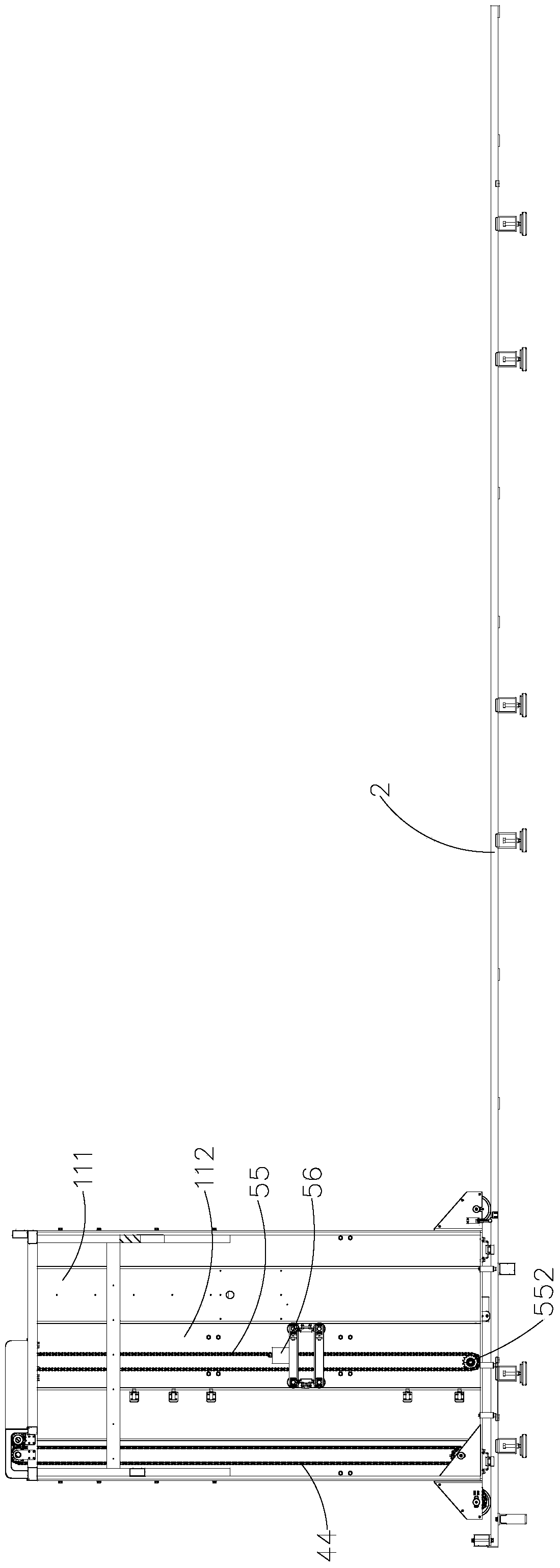

[0035] Please also refer to Figure 1 to Figure 9 The cloth roll conveying device of the multilayer spreading machine of the present invention comprises a frame 1, a conveying guide rail 2, a cloth roll conveying mechanism 3, a first driving mechanism 4 and a second driving mechanism 5, the cloth rolling conveying mechanism 3, the first Both the driving mechanism 4 and the second driving mechanism 5 are installed on the frame 1, the frame 1 is installed on the conveying guide rail 2, and the first driving mechanism 4 drives the cloth roll conveying mechanism 3 The frame 1 reciprocates horizontally along the conveying guide rail 2, the second drive mechanism 5 drives the cloth roll conveying mechanism 3 to reciprocate up and down along the frame 1, and the cloth roll conveying mechanism 3 includes a The cloth roll carrying mechanism 31 and the turning mechanism 32, the turning mechanism 32 drives the cloth rolling carrying mechanism 31 to turn over in a predetermined direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com