Renovating method for gaps and mud spillover between CRTSI template type ballastless track base plate and surface layer of roadbed of high-speed railway

A technology for slab-type ballastless track and high-speed railway, which is applied in the direction of track, ballast layer, road, etc., and can solve the problem of slurry damage to closed materials, water accumulation on the base plate and roadbed surface, and influence on train safety, comfort and smoothness and other problems, to achieve the effect of ensuring smoothness, precise operation and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

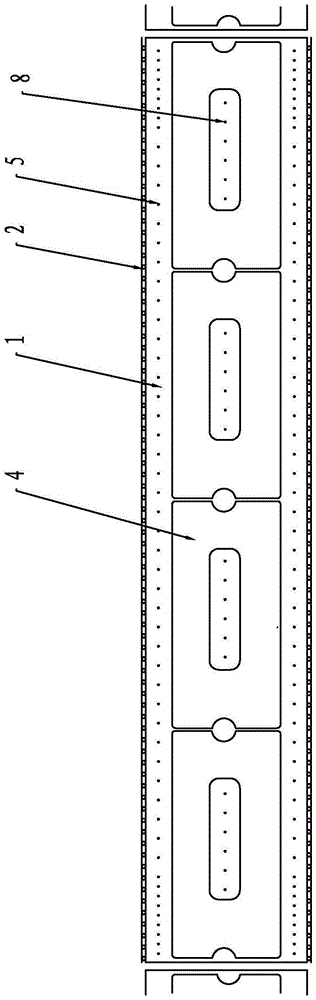

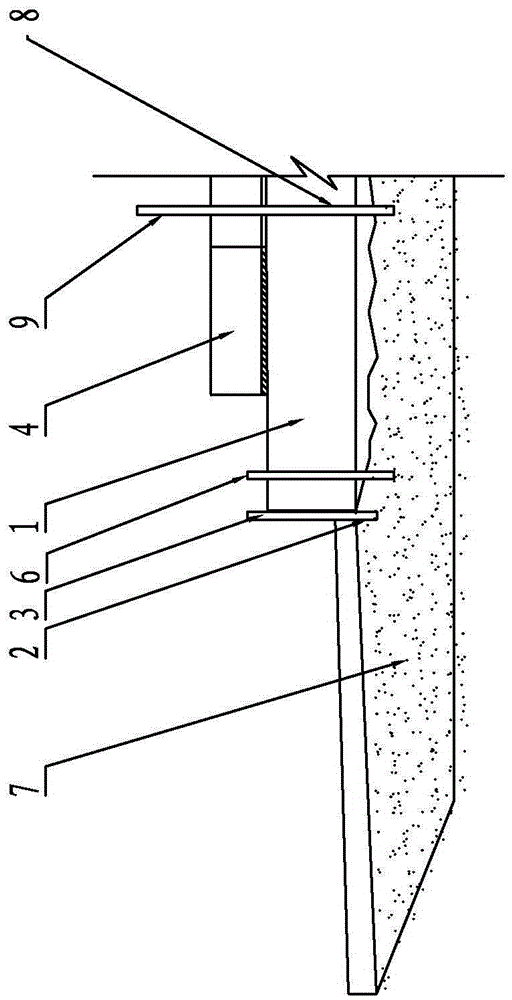

[0034] Such as figure 1 , figure 2 As shown, the high-speed railway CRTSI type frame slab ballastless track, that is, the track slab 4 is a frame slab, because the sealing material of the side seam of the base plate 1 is aged and damaged, and the gap between the base plate 1 and the surface layer of the subgrade 7 leaks slurry, the treatment method of the present invention is adopted Repair, including the following steps:

[0035] (1) Clean up the sealing materials for the side seams on both sides of the base plate 1, drill and arrange closed holes 2 at the side seams, the depth of the closed holes 2 is drilled to 2 cm of the subgrade gravel layer, the diameter of the closed holes 2 is 5 mm, and the hole spacing is 10 mm, and then Insert the grouting pipe 3 in the closed hole 2;

[0036] (2) Drill grouting holes 5 and 8 on both sides of the base plate 1 and the openings of the track plate 4 along the centerline. Drilling holes within 200mm at both ends should be properly i...

Embodiment 2

[0044] The sealing material of the side seam of the base plate of the CRTSI frame plate ballastless track of the high-speed railway is aged and damaged, and the gap between the base plate and the surface of the subgrade is leaked. The repair method of the present invention is used to repair it, including the following steps:

[0045](1) Clean up the sealing materials for the side seams on both sides of the base plate, drill and arrange closed holes at the side seams, the depth of the closed holes is drilled to 3cm in the subgrade gravel layer, the diameter of the closed holes is controlled at 15mm, and the distance between the holes is controlled at 20mm. Insert the grouting pipe into the hole;

[0046] (2) Drill grouting holes along the center line on both sides of the base plate and the openings of the track plate. The diameter of the grouting hole is controlled at 15mm, and the depth is drilled to 5cm of the gravel layer. The holes at both ends of the base plate within 200mm...

Embodiment 3

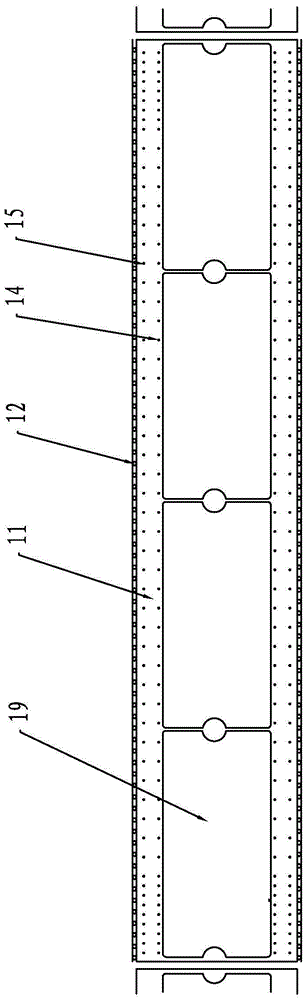

[0054] Such as image 3 with Figure 4 As shown, the high-speed railway CRTSI type solid slab ballastless track, that is, the track slab 19 is a solid slab. Due to the aging and damage of the sealing material of the side seam of the base plate 11, the gap between the base plate 11 and the surface layer of the roadbed 18 leaks slurry, and the treatment method of the present invention is adopted. Repair, including the following steps:

[0055] (1) Clean up the sealing materials for the side seams on both sides of the base plate 11, drill and arrange closed holes 12 at the side seams, the depth of the closed holes 12 is drilled to 2.5cm of the subgrade gravel layer, the diameter of the closed holes 12 is 10mm, and the hole spacing is 15mm, Then insert the grouting pipe 13 in the closed hole 12;

[0056] (2) Two rows of grouting holes 14 and 15 are respectively drilled on both sides of the base plate 11, a row of vertical drilling holes on the outside, and a row of drilling hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com