A kind of manufacturing method of anti-folding board bending board for building decoration

A technology of anti-folding special board and architectural decoration, which is applied in construction, building structure, floor and other directions, can solve the problems of chromatic aberration cost, defects, unsatisfactory customer results, etc., so as to save processing costs and improve production efficiency. , colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

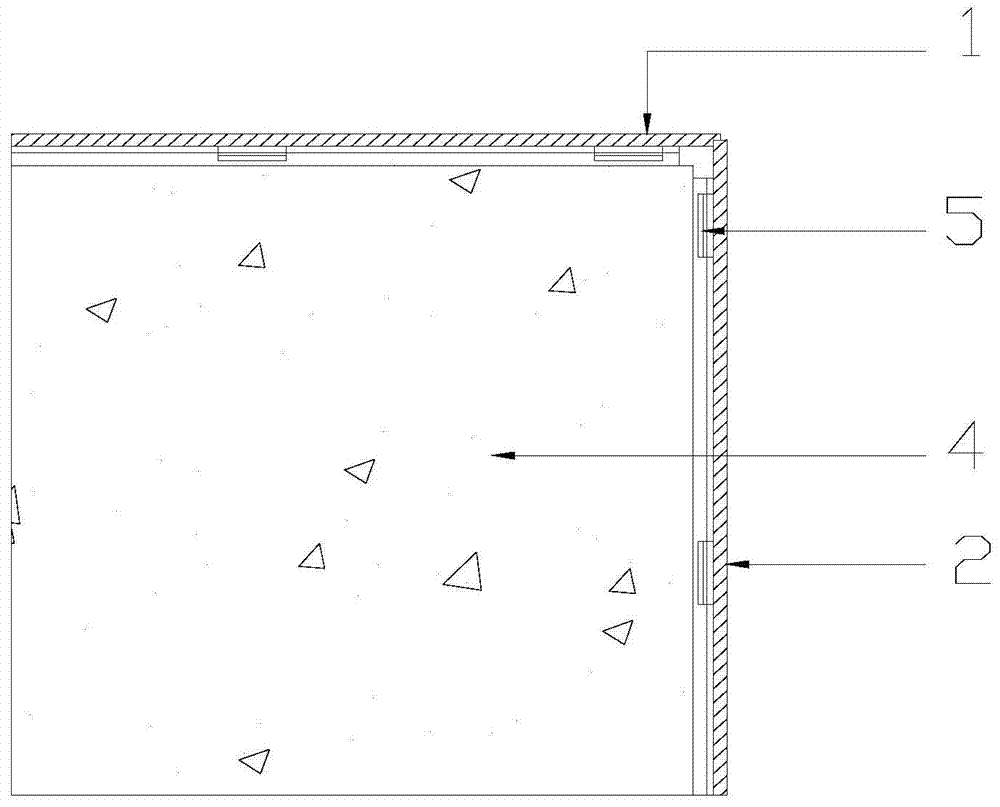

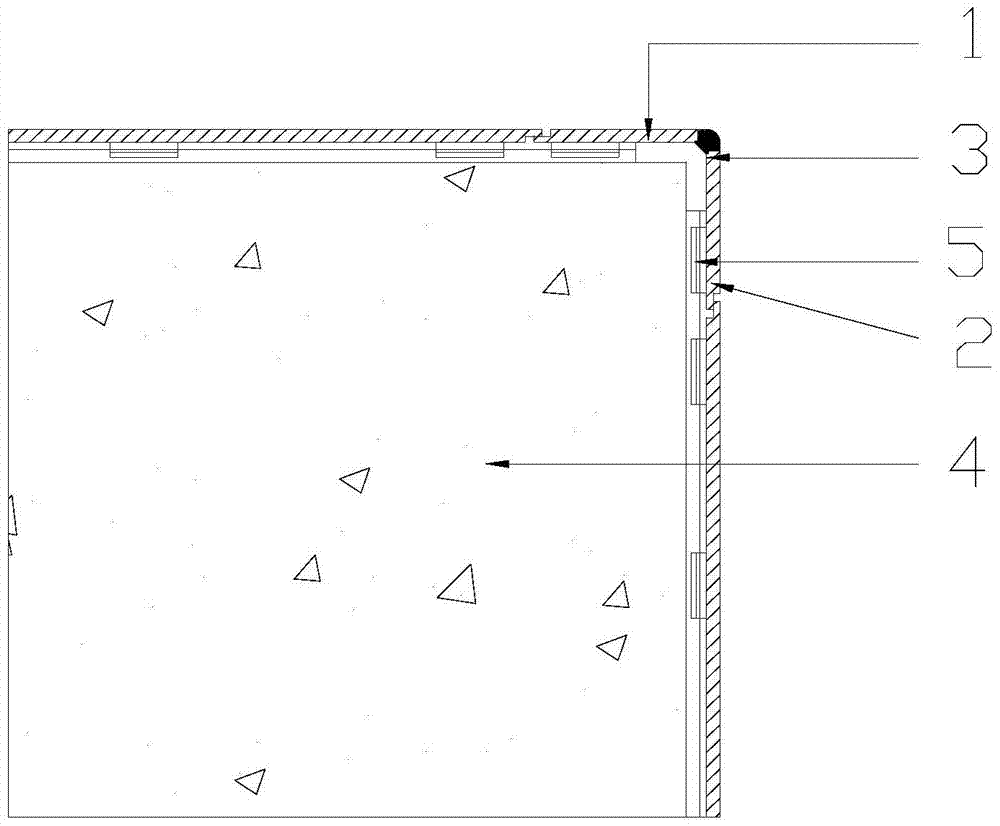

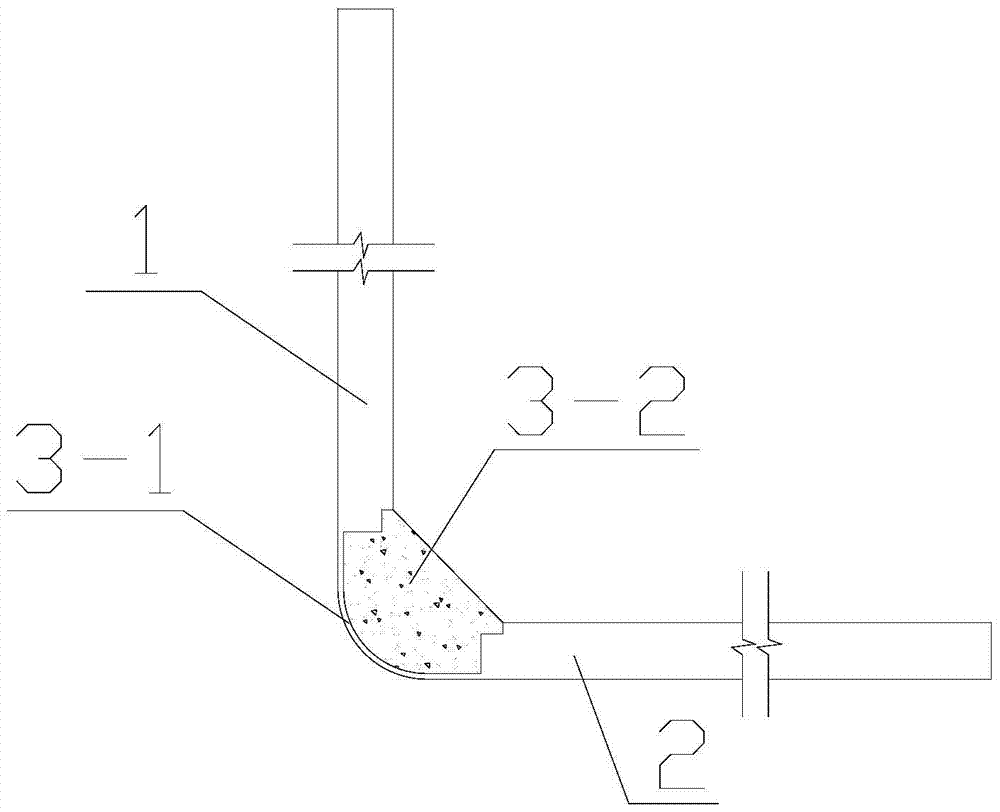

[0043] A kind of anti-fold special plate bending plate used for architectural decoration in this embodiment, its structure is as follows image 3 As shown, it includes a first flat board, a second flat board and a corner board. The first flat board and the second flat board are arranged at right angles. The corner board is arranged at the junction of the first flat board and the second flat board, and the The junction of the two plates forms a rounded structure; the arc radius R of the corner plate is 8-20 mm, and rubber blocks are arranged inside the corner plate. Among them, the rubber block uses its weight and shape to stabilize the shape of the corner plate. On the one hand, it keeps it stable and does not deform. It is beyond the reach of existing curved plates.

[0044] Among them, the corner plate includes a plate body and a rubber block. The thickness of the plate body is less than or equal to 1mm. The plate body is arc-shaped, and one side of the rubber block is an a...

Embodiment 2

[0050] In this embodiment, a method for manufacturing the anti-folding plate bending plate for architectural decoration described in Example 1 comprises the following steps:

[0051] (1) Design the mold: According to the arc radius R of the corner plate, the length of the 90° corner position on the corresponding design mold; wherein, the material of the mold is also an anti-folding plate, and the outer arc surface of the corner of the mold and the corner of the corner plate The inner wall surface is consistent, and 3mm space is reserved on the upper and lower end surfaces for the rebound space of the corner plate, such as Figure 5 In the label a shown.

[0052] (2) Grooving: CNC equipment is used to open a through groove on the anti-folding plate. The corresponding position of the through groove is the plate body of the corner plate. The two sides of the through groove are the first flat plate and the second flat plate respectively. The bottom of the through groove Thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com