A pulse blowback valve

A pulse blowback and valve stem technology, which is applied in the direction of valve lift, valve device, engine components, etc., can solve the problems that affect the effect of backwash cleaning process, complex flow channel structure, and large flow resistance loss, so as to prevent friction and improve Process effect, effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

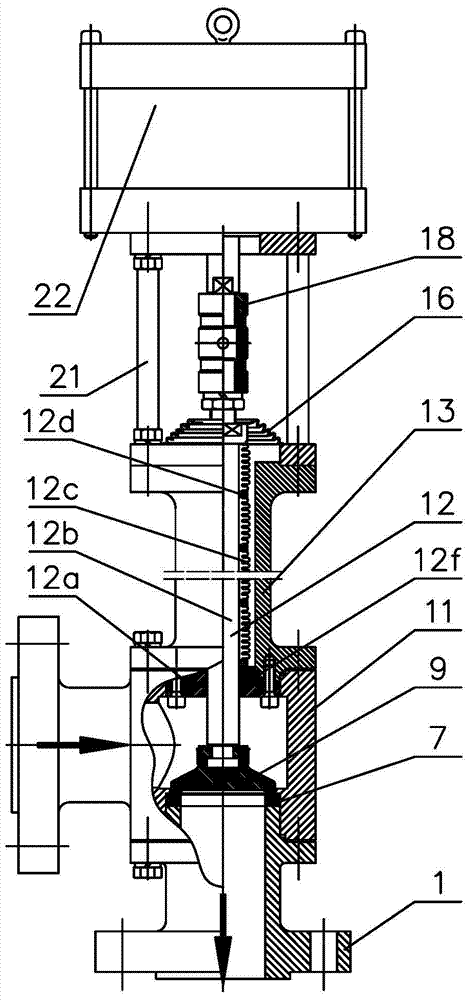

[0028] Combine below Figure 1-6 The structure of the present invention is further described:

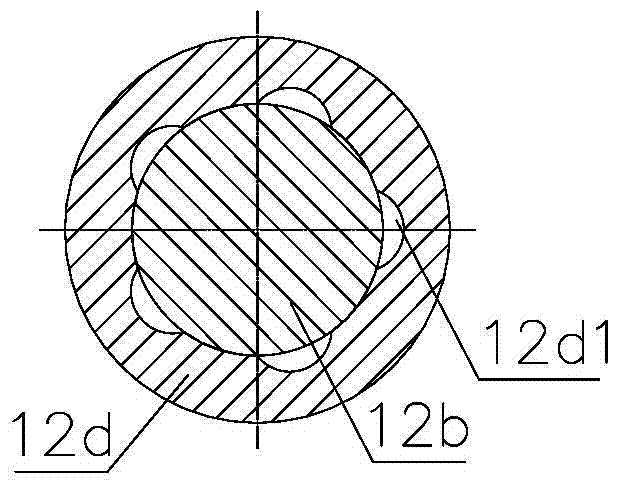

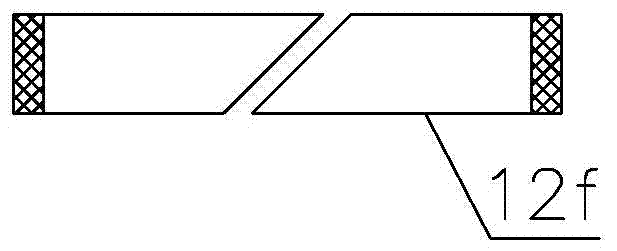

[0029] The pulse blowback valve of the present invention includes a bellows valve stem assembly 12, the bellows valve stem assembly 12 includes a valve stem 12b, and a bellows 12c with a gap sleeved outside the valve stem 12b, and the bellows 12c includes a A plurality of bellows sections connected in sequence in the axial direction of the valve stem are connected with each other through a centralizing ring 12d sleeved on the valve stem 12b. In the present invention, the bellows 12c is composed of multiple sections and the adjacent bellows sections are connected by a centralizing ring 12d. This structure can effectively improve the overall rigidity of the bellows 12c and avoid the instability of the bellows 12c during the back and forth movement of the valve stem 12b. And the problem of friction with the valve stem 12b, the present invention effectively protects the bellows 12c.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com