Stop type anti-scaling valve element sleeved with film and valve comprising valve element

An anti-scaling and valve core technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of inability to adjust, loose, complex assembly, etc., achieve good market promotion value, high product practicability, simple and effective structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

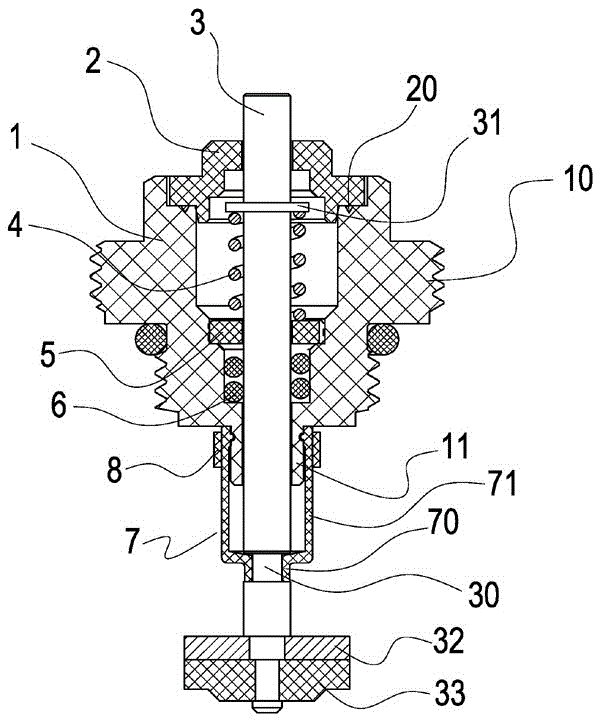

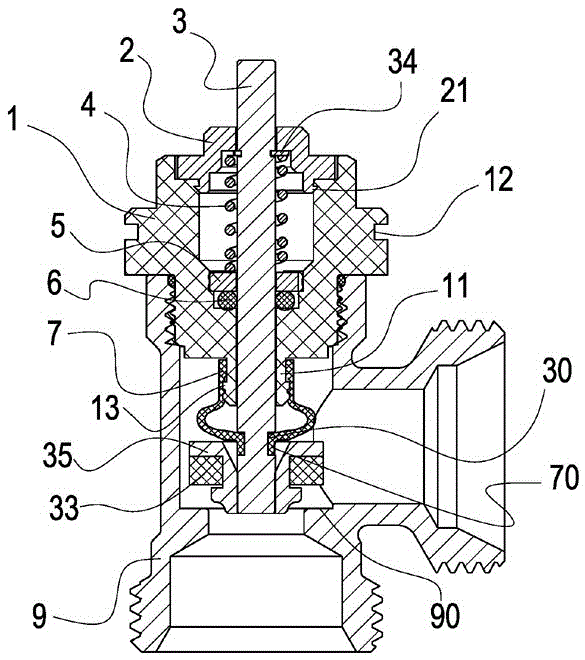

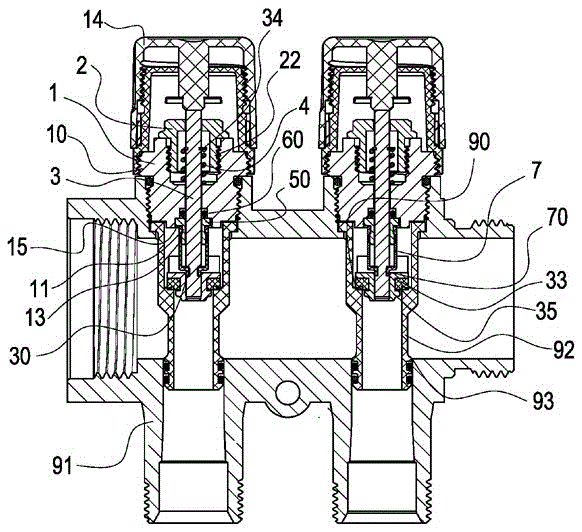

[0020] The cut-off mantle anti-scaling valve core and its valve of the preferred embodiment of the present invention will be further described below with reference to the accompanying drawings.

[0021] Such as figure 1 As shown, a cut-off mantle film anti-scaling valve core includes a valve core body 1, an external thread part 10 is provided on the outside of the valve core body 1, and the size of the external thread part 10 is M30x1.5; An annular body 11 extends from the lower end; the top of the valve core body 1 is provided with a valve cover 2, and the lower part of the valve cover 2 is provided with an annular part 20 with a triangular cross-section; the valve core body 1 and the valve cover 2 are made of plastic material and welded together One body; a cylindrical valve stem 3 runs through the inner cavity of the valve core body 1, and the valve stem 3 is provided with an annular groove 30 at the lower end of the valve core body 1; The upper end rests on the flange rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com