A kind of building sealant fatigue resistance testing equipment

A technology of fatigue resistance and testing equipment, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of complex structure, high cost, complicated use, etc., and achieve small size, low cost, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

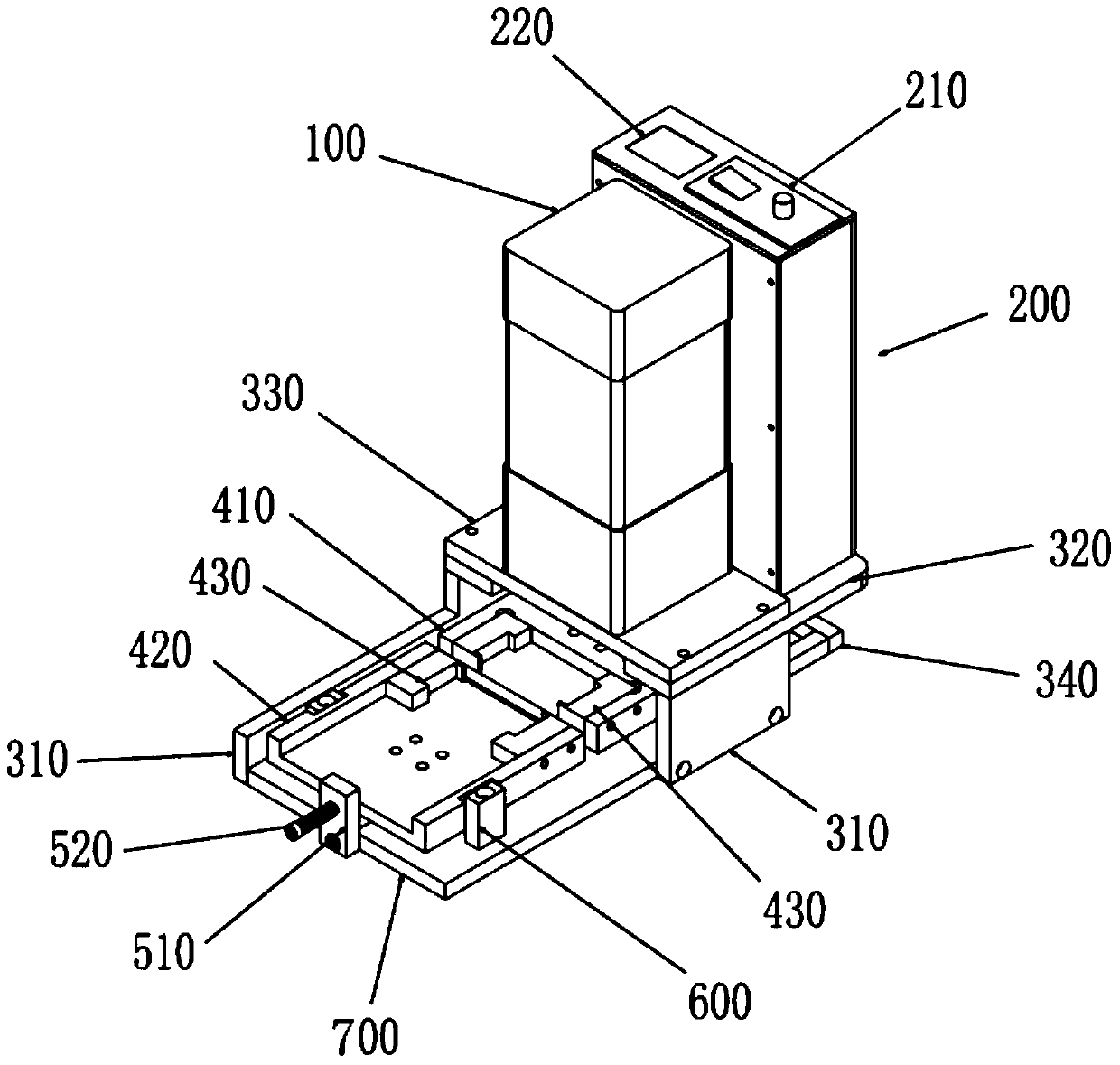

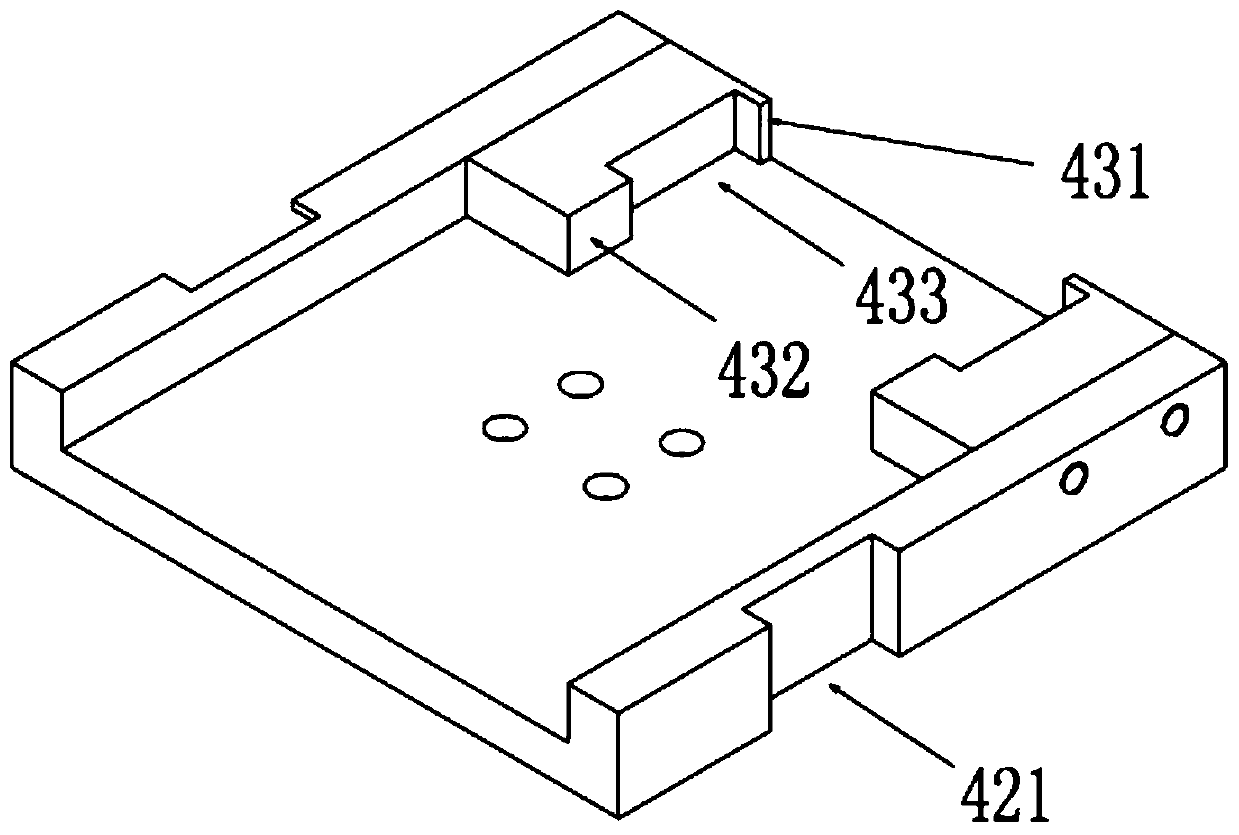

[0027] like figure 1 As shown, the present embodiment provides a building sealant fatigue resistance test equipment, which is characterized in that it includes a base plate 700, a first adjustment plate 410, a second adjustment plate 420, a pull-back device, a power device and a control device 200; the base plate The upper surface of the bottom plate 700 is flat, and the first adjusting plate 410 and the second adjusting plate 420 are adjacently placed on the upper surface of the bottom plate 700. The adjacent positions of the first adjusting plate 410 and the second adjusting plate 420 respectively have clamping ends of workpieces to be measured. The clamping position of the part; the anti-pull device is installed on the bottom plate 700 and the second adjusting plate 420 is fixed relatively to the bottom plate 700; the power end of the power device is connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com