Touch substrate, manufacturing method and display device

A technology for display devices and substrates, applied in optics, instruments, electrical digital data processing, etc., can solve problems affecting touch sensing accuracy, assembly tolerances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

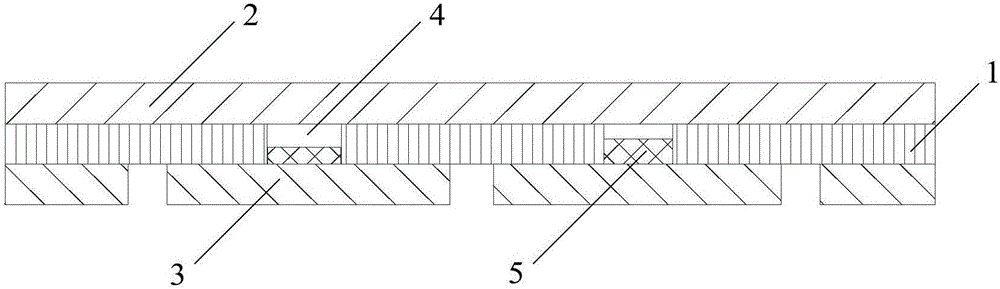

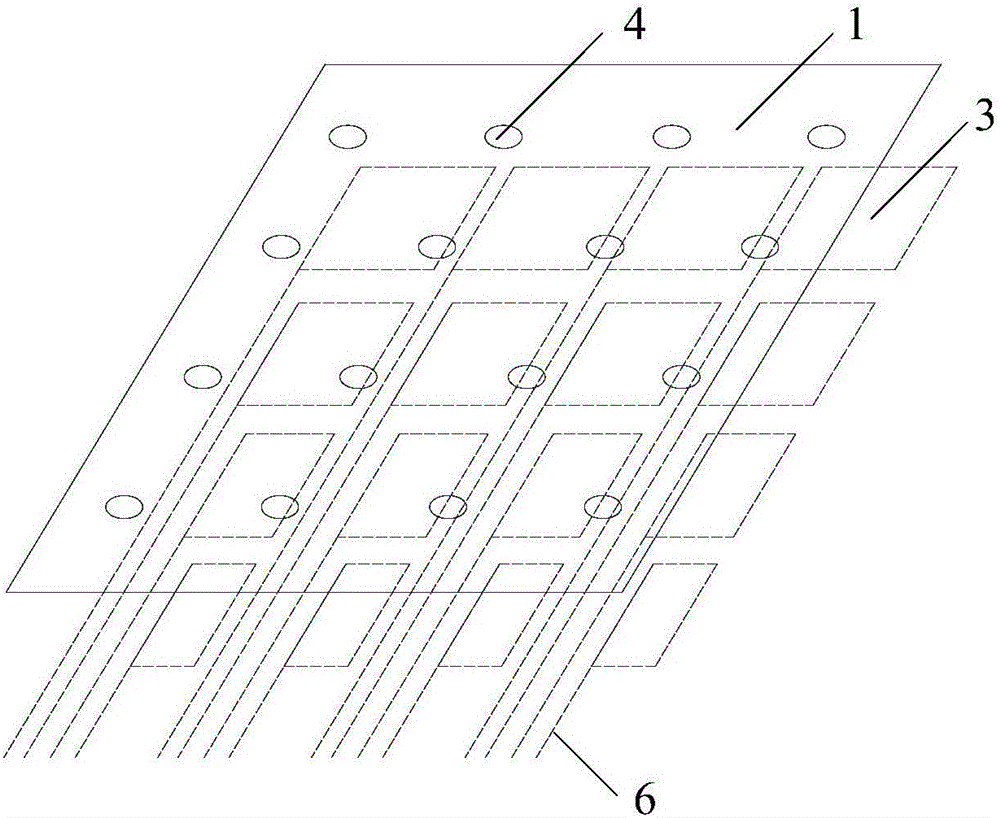

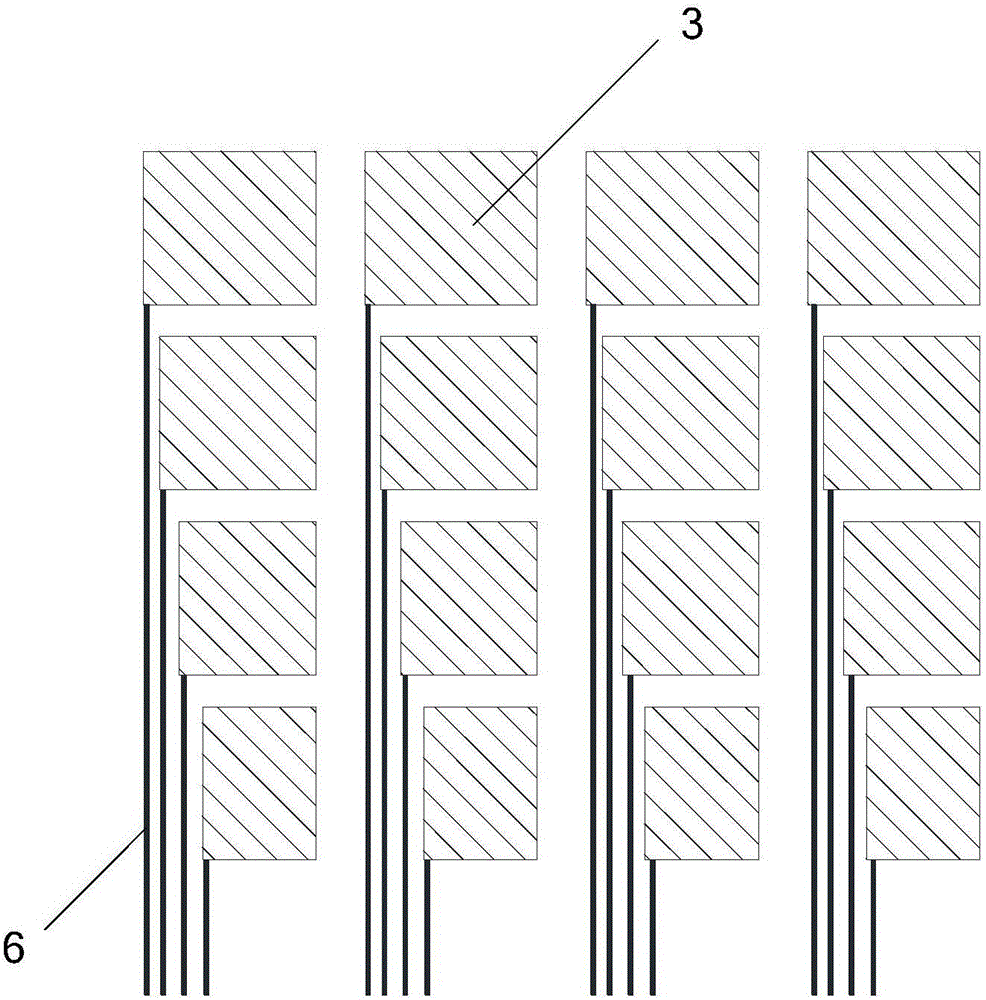

[0038] An embodiment of the present invention provides a touch substrate, such as figure 1 , figure 2 As shown, the touch control substrate includes a substrate 1 provided with several through holes 4; on the first surface (upper surface) of the substrate 1, a first electrode 2 covering several through holes 4 is formed (not in the figure 2 shown in ); on the second surface (lower surface) of the substrate 1 opposite to the first surface, a plurality of second electrodes 3 each corresponding to a touch area are formed; the second electrodes 3 are at least partially in at least one place Surrounding the edge of the through hole 4; the through hole 4 is provided with an elastic conductor block 5 for forming an electrical connection between the first electrode 2 and the second electrode 3 at both ends of the through hole 4 when the substrate 1 is pressed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap