Fully automatic module integration system and method based on component factory

A fully automatic and component technology, applied in the direction of program control devices, etc., can solve problems such as inability to form product management, complex interface definitions and documents, and inability to effectively locate whether functional module interfaces are completely replaced or cancelled, so as to achieve reasonable and effective interaction management And the effect of storage and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

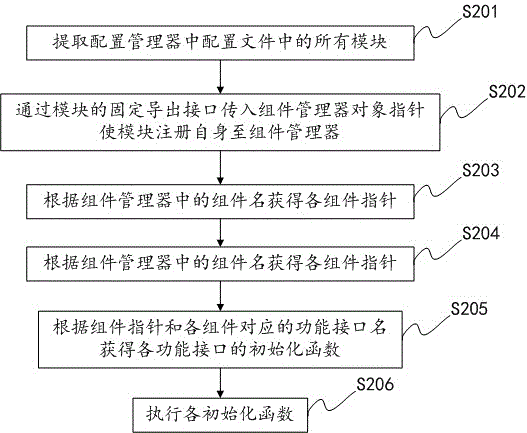

[0040] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purposes, features and advantages of the present invention more obvious and easy to understand, the technical solutions in the present invention will be further detailed below in conjunction with the accompanying drawings illustrate.

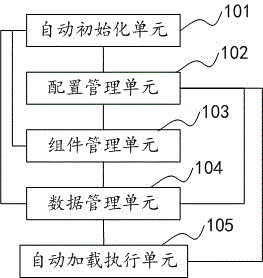

[0041] The present invention provides a system embodiment of fully automatic module integration based on component factories, such as figure 1 shown, including:

[0042] Automatic initialization unit 101 for

[0043] Extract all the modules in the configuration file in the configuration management unit 102;

[0044] Through the fixed export interface of the module, the object pointer of the component management unit 103 is passed in, so that the module registers itself to the component management unit 103 and becomes a component to be used;

[0045] Obtain each component p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com