High-temperature composite phase-change heat storage material with multi-core-shell structure, and preparation method and application thereof

A technology of composite phase change and heat storage materials, applied in the field of heat storage materials, can solve the problems of harsh selection of phase change materials and ceramic materials, loss and evaporation of molten salt, limited content of inorganic salts, etc., and achieve excellent high temperature stability and mechanical Strength, good thermal conductivity, high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

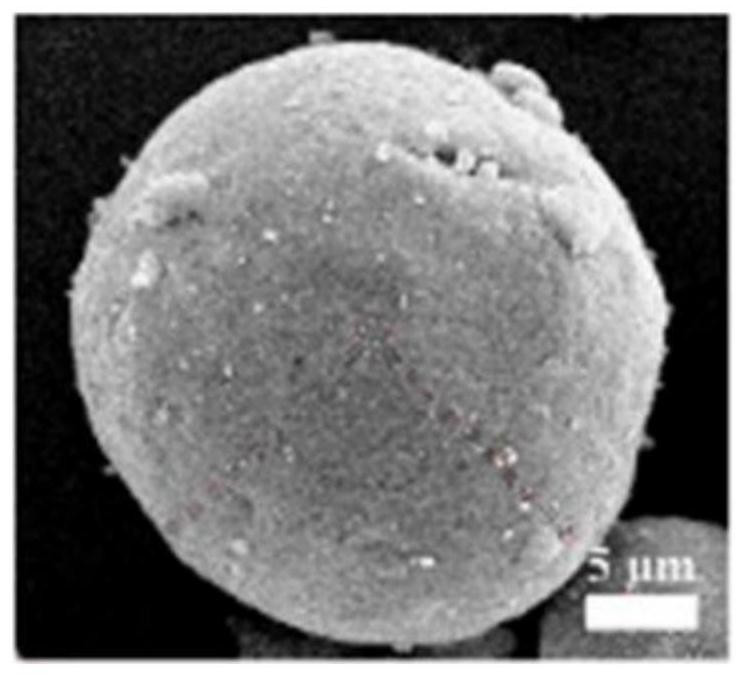

Image

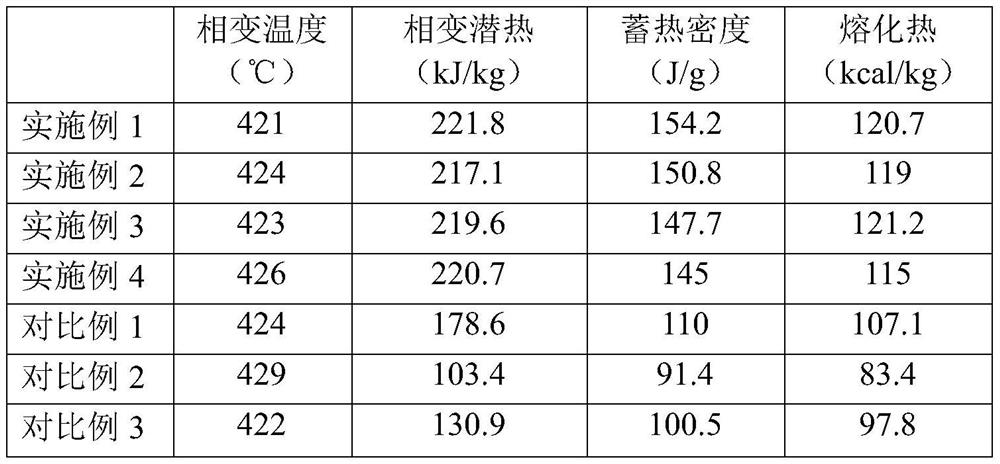

Examples

Embodiment 1

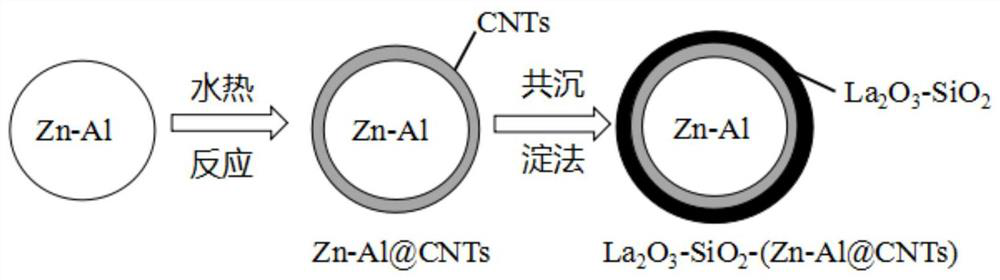

[0048] A method for preparing a high-temperature composite phase-change heat storage material with a multi-core-shell structure, the specific steps are as follows:

[0049] S1. Add zinc-aluminum alloy powder to distilled water to prepare a zinc-aluminum alloy powder turbid solution, place the turbid solution in an ultrasonic disperser and perform ultrasonic treatment for 30 minutes to obtain a zinc-aluminum alloy powder suspension; the concentration of the zinc-aluminum alloy powder turbid solution is 20g / L;

[0050] S2. adding carbon nanotubes (CNTs) to absolute ethanol and then dispersing them under ultrasonic conditions for 1 hour to obtain a suspension of carbon nanotubes (CNTs);

[0051] S3. Mix the zinc-aluminum alloy powder suspension in S1 and the carbon nanotube (CNTs) suspension in S2 at a mass ratio of 1:4, put them in an autoclave at 120°C for hydrothermal reaction for 12 hours, and cool to room temperature, filter, wash the solid with distilled water and absolute...

Embodiment 2

[0061] A method for preparing a high-temperature composite phase-change heat storage material with a multi-core-shell structure, the specific steps are as follows:

[0062] S1. Add zinc-aluminum alloy powder to distilled water to prepare a zinc-aluminum alloy powder turbid solution, place the turbid solution in an ultrasonic disperser and perform ultrasonic treatment for 40 minutes to obtain a zinc-aluminum alloy powder suspension; the concentration of the zinc-aluminum alloy powder turbid solution is 30g / L;

[0063] S2. adding carbon nanotubes (CNTs) to absolute ethanol and then dispersing them under ultrasonic conditions for 2 hours to obtain a suspension of carbon nanotubes (CNTs);

[0064] S3. Mix the zinc-aluminum alloy powder suspension in S1 and the carbon nanotube (CNTs) suspension in S2 at a mass ratio of 1:5, put them in an autoclave at 130°C for hydrothermal reaction for 16 hours, and cool to room temperature, filter, wash the solid with distilled water and absolut...

Embodiment 3

[0073] A method for preparing a high-temperature composite phase-change heat storage material with a multi-core-shell structure, the specific steps are as follows:

[0074] S1. Add zinc-aluminum alloy powder to distilled water to prepare a zinc-aluminum alloy powder turbid solution, place the turbid solution in an ultrasonic disperser and perform ultrasonic treatment for 50 minutes to obtain a zinc-aluminum alloy powder suspension; the concentration of the zinc-aluminum alloy powder turbid solution is 40g / L;

[0075] S2. adding carbon nanotubes (CNTs) to absolute ethanol and then dispersing them under ultrasonic conditions for 2.5 hours to obtain a suspension of carbon nanotubes (CNTs);

[0076] S3. Mix the zinc-aluminum alloy powder suspension in S1 and the carbon nanotube (CNTs) suspension in S2 at a mass ratio of 1:6, put them in a high-pressure reactor at a temperature of 140°C for hydrothermal reaction for 20 hours, and cool to room temperature, filter, wash the solid wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com