Internal mold structure facilitating demolding

A demoulding and convenient technology, applied in the direction of unloading devices, manufacturing tools, etc., can solve the problems of inconvenient support and fixing, lack of lifting and handling tools, inconvenient demoulding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

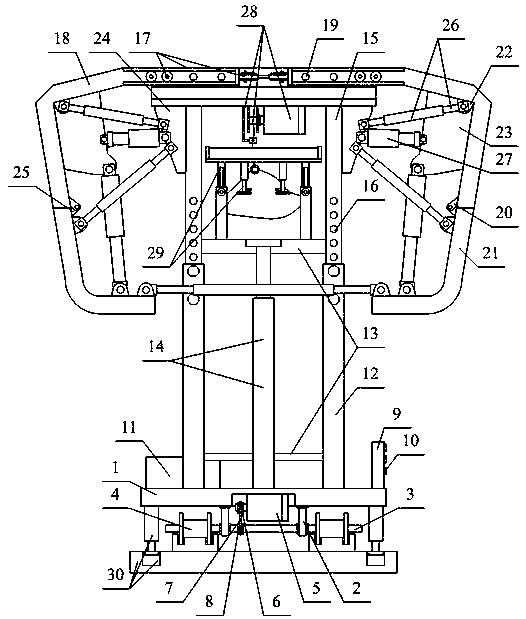

[0046] as attached figure 1 to the attached figure 2 As shown, an inner mold structure for easy demoulding includes base 1, bearing seat 2, connecting shaft 3, traveling wheel 4, moving motor 5, driving sprocket 6, chain 7, driven sprocket 8, PLC9, switch 10. Hydraulic station 11, lower column 12, reinforced rod frame 13, lifting hydraulic cylinder 14, upper insertion column 15, penetration hole 16, auxiliary movable support seat structure 17, upper cover plate 18, plug-in steel rod head 19, The upper corner 20, the lower cover plate 21, the connecting seat 22, the first bracket 23, the second bracket 24, the lower corner 25, the lead screw 26, the rotary hydraulic cylinder 27, the auxiliary hoisting rail structure 28, the auxiliary support table structure 29 and Supporting the protective seat structure 30, the bearing seat 2 is respectively bolted to the front and rear parts of the left side and the middle right side of the lower surface of the base 1; the connecting shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com