valve

A technology of valve core and valve sleeve, which is applied in the field of valves, can solve the problem of increasing the burden of switching speed and achieve the effect of small sliding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Unless otherwise stated, the following explanations apply to all embodiments.

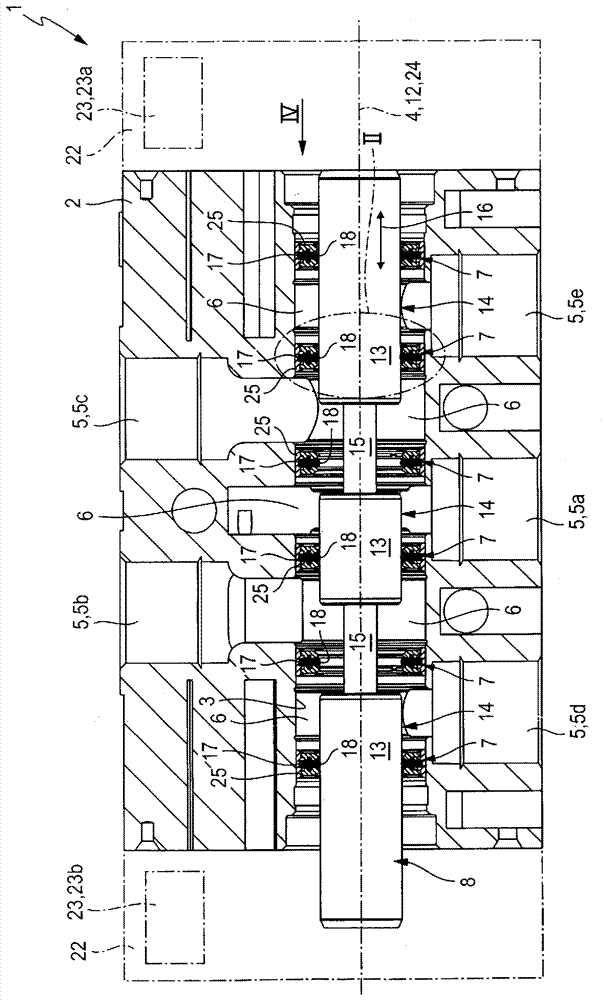

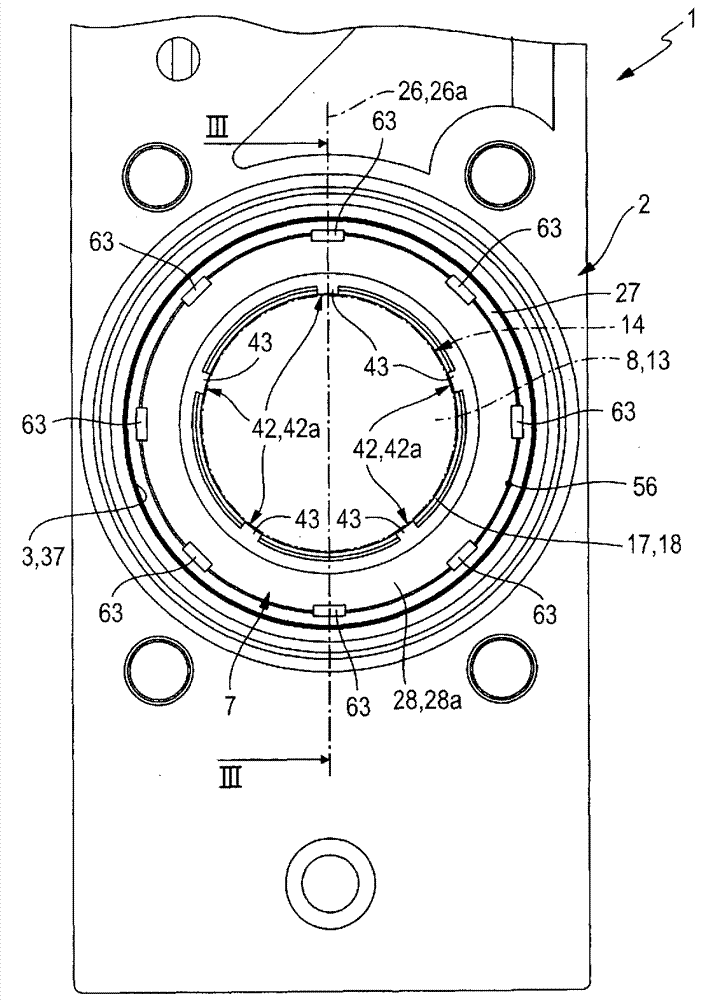

[0032] The valve indicated overall by the reference numeral 1 preferably has the design as a multi-way valve and has a valve housing 2 in which a recess 3 having a linear elongated, preferably cylindrical contour, is formed. The recess 3 has an imaginary central longitudinal axis 4 which is outlined with a dash-dotted line.

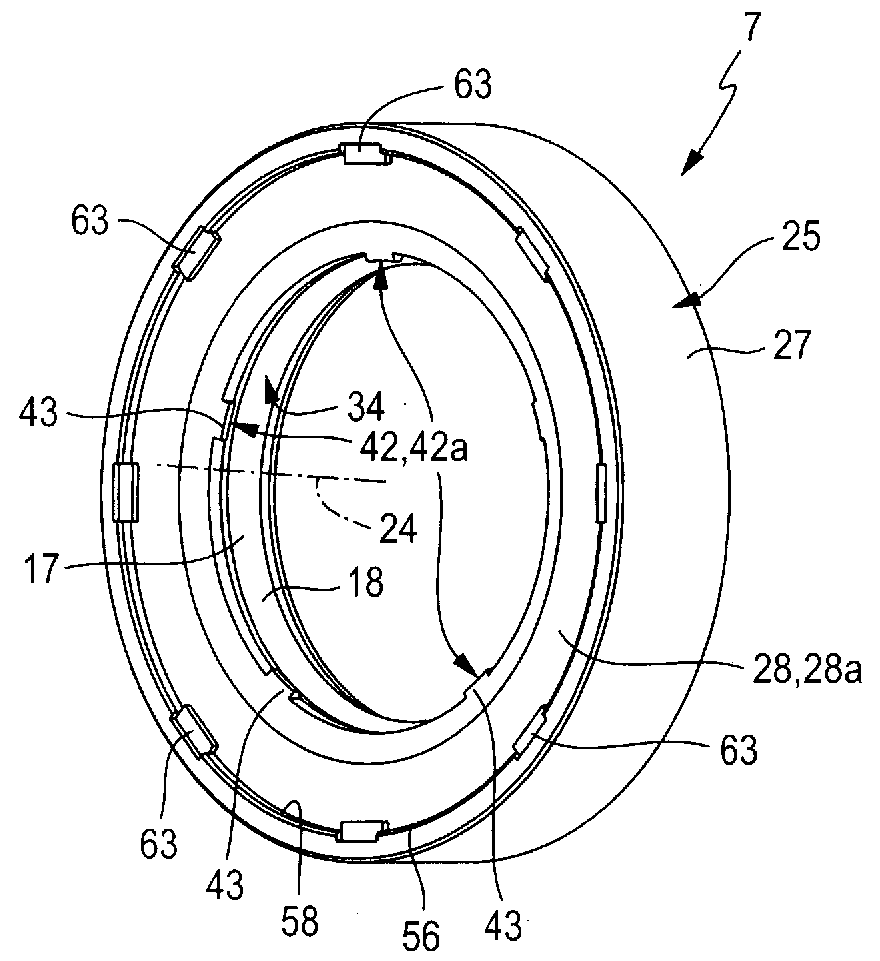

[0033] A plurality of valve channels 5 , which pass through the valve housing 2 , open into the recess 3 at locations axially spaced from one another in the periphery. Between the gap section 6 of the gap 3 that communicates with a corresponding one of the valve passages 5, a corresponding sealing ring 7 with a special structure is placed in the gap 3, and further The structure of the sealing ring is discussed. In any case, preferably a plurality of sealing rings 7 having a coaxial arrangement and an axial spacing from one another are arranged in the recess 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com