Water pump water seal floating assembly method and floating tool

An assembly method and water sealing technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., to achieve the effect of avoiding being pulled and eliminating excessive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

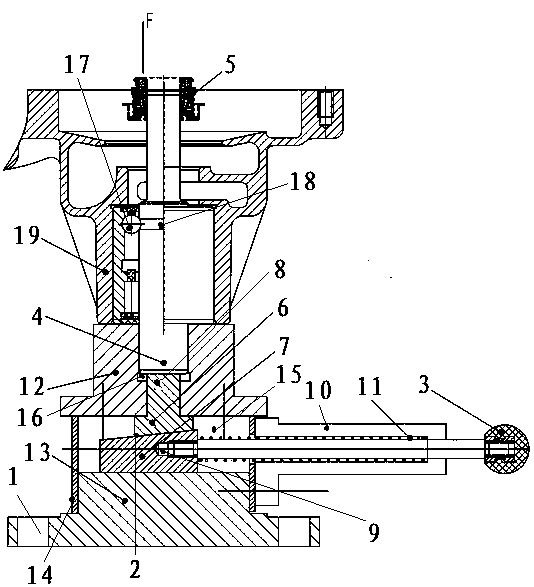

Embodiment 1

[0030] The wedge iron self-locking adjustment mechanism 2 includes an upper wedge iron 6 and a lower wedge iron 7, wherein the upper wedge iron 6 is connected with the moving block 8 installed in the shaft hole 16 of the water pump, and the upper wedge iron 7 only It can move up and down together with the moving block 8; the lower wedge iron 7 is located under the upper wedge iron 6, and the upper wedge iron 6 and the lower wedge iron 7 adopt self-locking slopes to be close together.

[0031] There is a screw hole 9 on the side of the lower wedge iron 7, one end of the manual adjustment handle 3 is installed in the screw hole 9, and the other end of the manual adjustment handle 3 is installed on the side of the water pump water seal installation tool base 1. Manually adjust the inside of the handle sleeve 10.

[0032] The manual adjustment handle 3 is covered with a compression spring 11, one head of the compression spring 11 is placed on the side of the lower wedge iron 7, an...

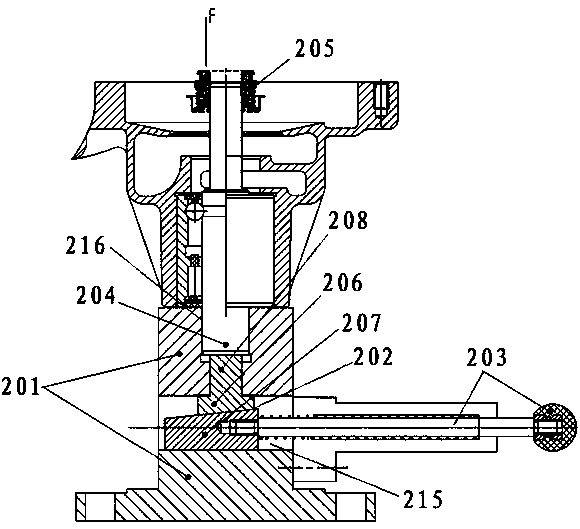

Embodiment 2

[0038] The water pump water seal installation tool base 201 is one piece, and a water pump shaft hole 216 is vertically opened on the upper end surface of the water pump water seal installation tool base 201, and a floating moving block capable of moving up and down is installed in the water pump shaft hole 216 208; There is a wedge iron installation hole 215 on the side of the water pump water seal installation tooling base, and the upper wedge iron 206 and the lower wedge iron 207 are installed in the wedge iron installation hole 215, and the upper wedge iron 206 and the floating moving block 208 are threaded. Firmly connected together, so that when the upper wedge iron 206 reciprocates laterally in the lower wedge iron 207, the upper wedge iron 206 can only drive the floating moving block 208 to move up and down.

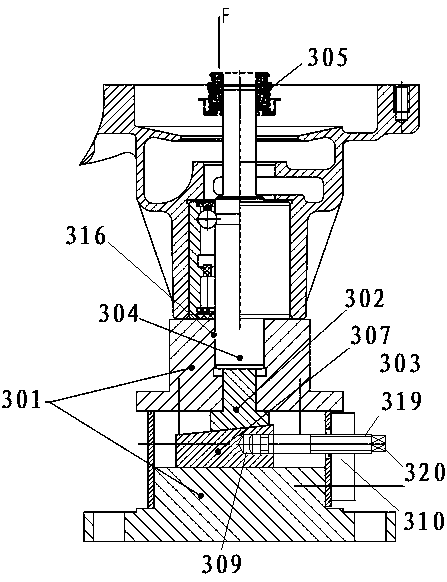

[0039] Embodiment three

Embodiment 3

[0041] There is a light hole 309 on the side of the lower wedge iron 307, one end of the manual adjustment handle 303 is inserted in the light hole 309, and can rotate in the light hole 309, and the other end of the manual adjustment handle 303 has an adjustment screw 319 , the adjustment screw 319 is installed in the manual adjustment handle nut 310 connected to the side of the water pump water seal installation tooling base, there is an operation handle 320 at the adjustment screw port, the manual adjustment handle 303 is rotated by the operation handle 320 to drive the manual adjustment handle to rotate, and at the same time The lower wedge iron 307 is driven to reciprocate by manually adjusting the handle 303 .

[0042] Apparently, the examples listed in this application are only examples for further describing the principle and structure of the present invention, and any improvements made based on the principle of the present invention should fall within the protection sco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com