A positioning fixture used in the construction of ship outfitting modules

A technology for positioning fixtures and outfitting parts, which is applied to manufacturing tools, workpiece clamping devices, etc., can solve the problems of waste of positioning fixtures, low efficiency, and difficulty in adjusting the spacing accuracy of outfitting parts, and achieves time saving, convenient operation and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

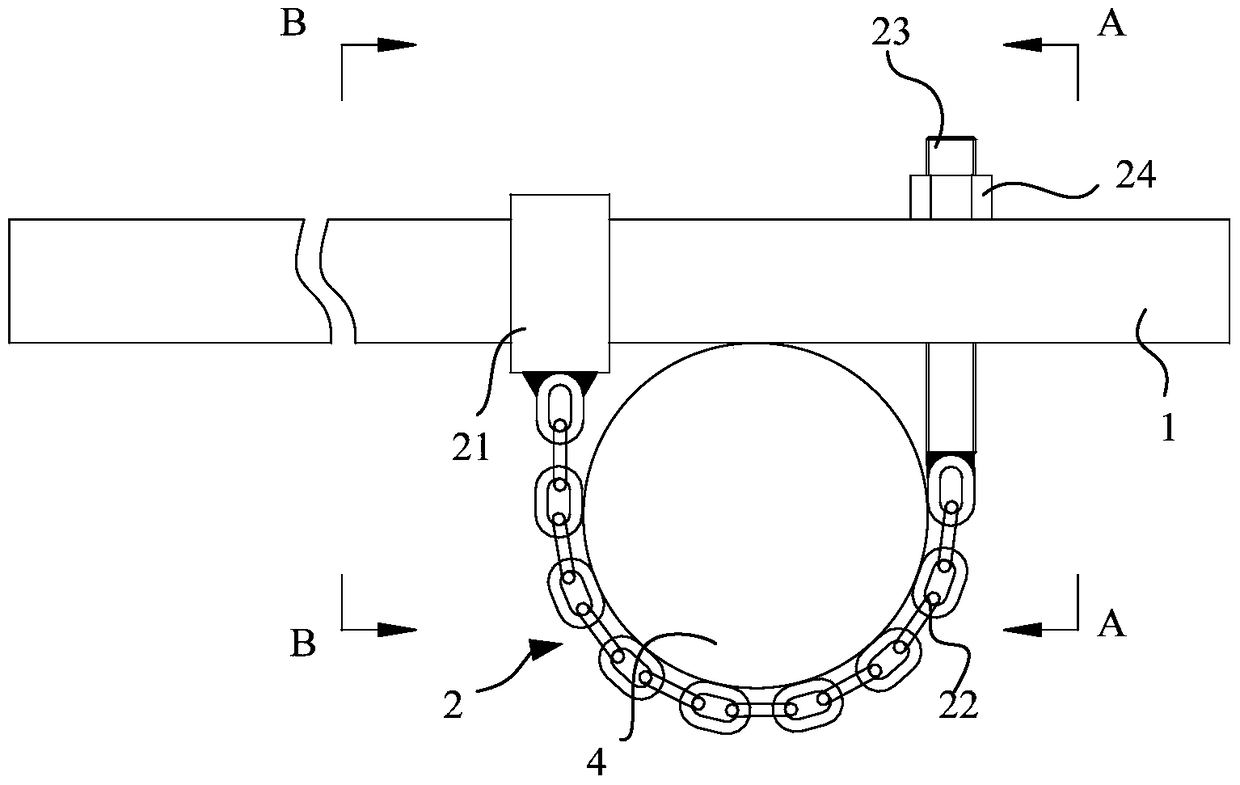

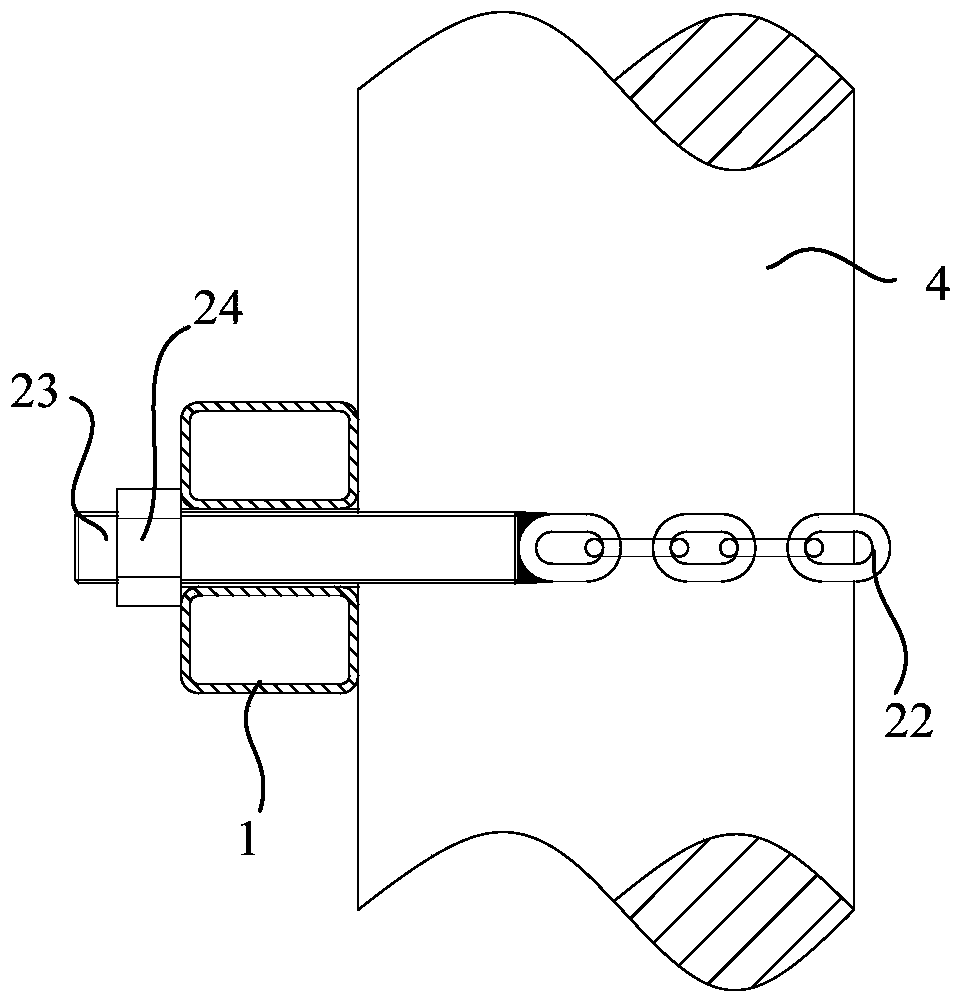

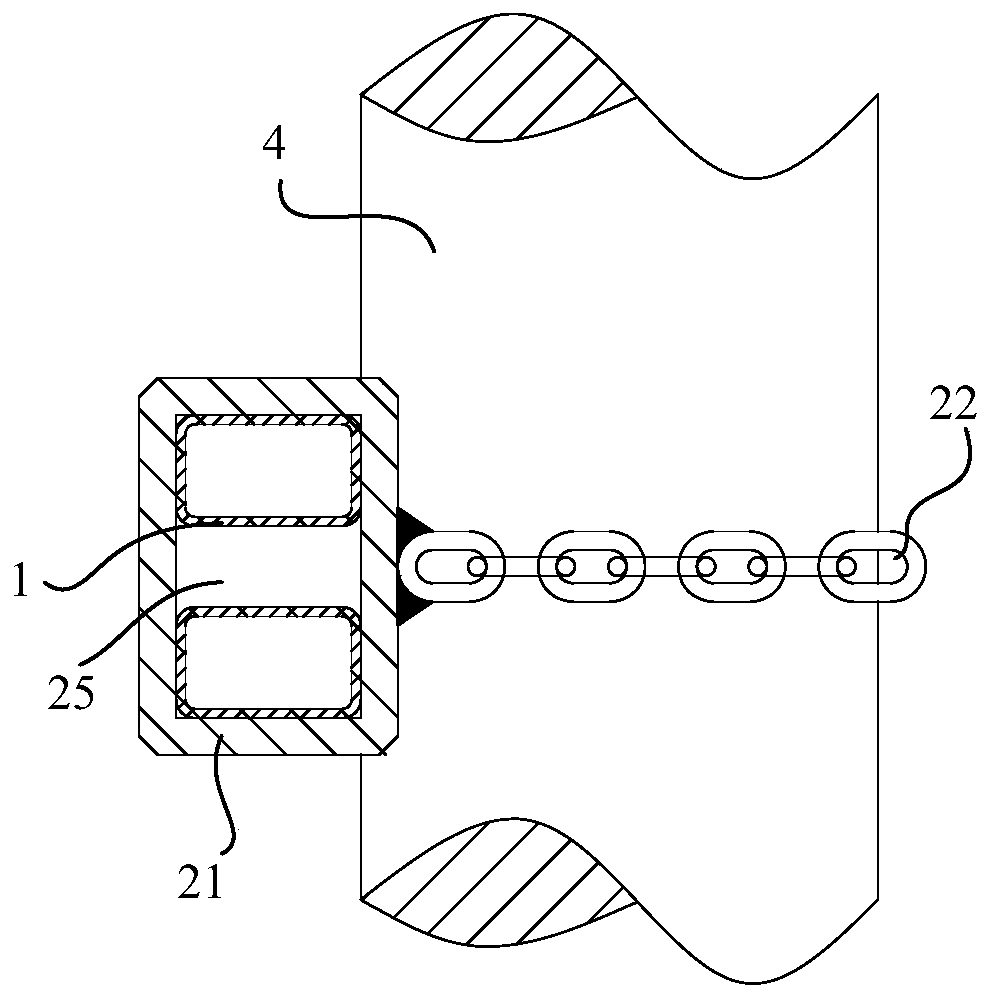

[0024] Such as figure 1 As shown, a positioning fixture used for the construction of ship outfitting modules includes a slide rail 1 and a sliding sleeve assembly 2. The sliding sleeve assembly 2 includes a sliding sleeve 21 slidably sleeved on the slide rail 1. The sliding sleeve 21 The chain 22 is connected to the fixed rod, the fixed rod can be detachably connected to the slide rail 1, and the different outfitting parts 4 in the outfitting module are fixed on the same sliding rail 1 through the sliding sleeve assembly 2, so that the outfitting parts 4 Fixed as a whole, the ship outfitting module can enter the next process as a whole, with high efficiency, and because the sliding sleeve assembly 2 can slide relative to the slide rail 1, it can clamp the outfitting parts 4 with irregular spacing, which is convenient for operation and saves time . The above-mentioned positioning fixture can be detachably matched with the outfitting 4, so it can be recycled to avoid waste.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com