A method for recovering rare earth rich liquid from volcanic rock ion type rare earth ore

A technology for ionic rare earth ore and volcanic rock, applied in the direction of improving process efficiency, can solve the problems of rare earth rich liquid loss, semi-weathered layer lithology is hard and cannot be excavated, loss and other problems, so as to improve the recovery rate and avoid recoverable rare earth resources. Quantity loss, improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

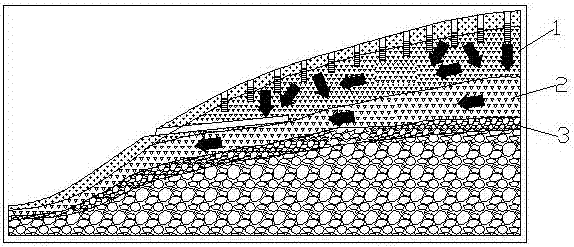

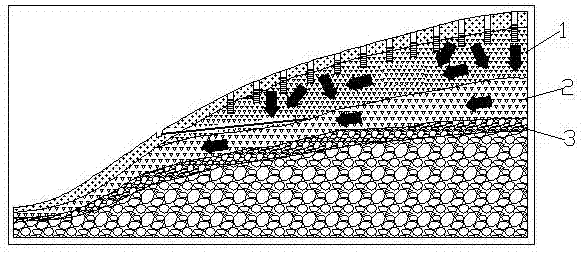

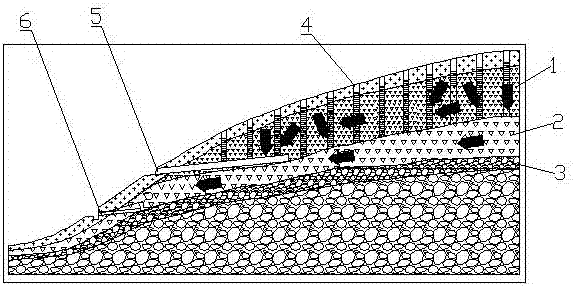

[0015] Such as image 3 As shown, the present invention is a method for reclaiming rare earth rich liquid from volcanic rock ion-type rare earth ore. Diversion roadway 5, the length of diversion roadway 5 extends to the semi-weathered layer 2; a diversion hole 6 with a diameter of 50-80 mm is set on the side of the semi-weathered layer 2 of the ore body near the slightly weathered layer 3, and the length of the diversion hole 6 extends to the slightly weathered layer 3. Layer 3; the ore body is provided with a liquid injection well 4 for pouring leaching liquid.

[0016] When the present invention is actually implemented, the guide hole 6 can be set according to the thickness of the actual semi-weathered layer 2, and can be set to 1~2 layers. When the semi-weathered layer 2 is thicker, two layers can be set, and when it is thinner, one layer can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com