A detachment prevention device for a torque rotary speed-increasing tool

An anti-dropping device and tool technology, applied in drilling equipment, earth-moving drilling, drill pipe and other directions, can solve the problems of tools falling into wells, disengagement of drill bit seat and tool housing, etc., achieving high reliability, easy assembly and disassembly, The effect of strong shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

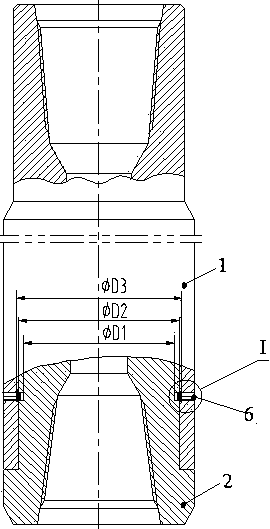

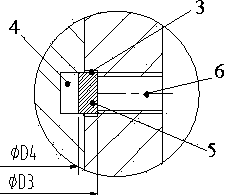

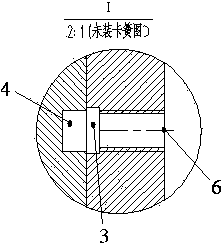

[0020] This embodiment provides a figure 1 The shown anti-off device of the torque rotation speed-up tool includes a tool housing 1 and a drill seat 2 connected to the lower end of the tool housing 1. The tool housing 1 and the drill seat 2 are connected by a clearance fit. The tool The lower end of the housing 1 is provided with a tool housing groove ring 3, and the upper end of the drill bit seat 2 is provided with a drill bit seat groove ring 4, and an anti-lock ring 4 is provided between the tool housing groove ring 3 and the drill bit seat groove ring 4. Take off the clip spring 5;

[0021] The diameter of the groove ring 3 of the tool housing is greater than the diameter of the groove ring 4 of the drill seat, and the tool housing 1 is uniformly provided with a plurality of threaded holes 6 in the circumferential direction, and the threaded holes 6 communicate with the groove ring 3 of the tool housing ;

[0022] The outer diameter of described anti-off jumper 5 is equ...

Embodiment 2

[0029] On the basis of Embodiment 1, this embodiment provides an anti-off device of a torque rotary speed-increasing tool. The difference in length is 3-8mm; the anti-off jumper 5 can be fully squeezed into the drill bit seat groove ring 4, and it is convenient for loading and unloading.

[0030] In this embodiment, the tool housing 1 is evenly provided with 3-6 threaded holes 6 in the circumferential direction, and the threaded holes 6 are M 8 , M 10 or M 12 .

[0031] To sum up, the anti-falling device of the torque rotary speed-increasing tool provided by the present invention can prevent the torque rotary speed-increasing tool from slipping, causing the drill bit seat 2, internal parts of the tool, and the drill bit to fall into the bottom of the well, causing drilling accidents. Compared with the prior art, it has the following advantages: simple and compact structure, strong shear strength, high reliability, and easy assembly and disassembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com