Stepless pressure reducing valve

A pressure reducing valve, stepless technology, applied in the field of pressure reducing valves, can solve problems such as increased use cost, increased installation, complexity, etc., and achieves the effects of saving pressure adjustment costs, reliable performance, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is further described below in conjunction with embodiment and accompanying drawing.

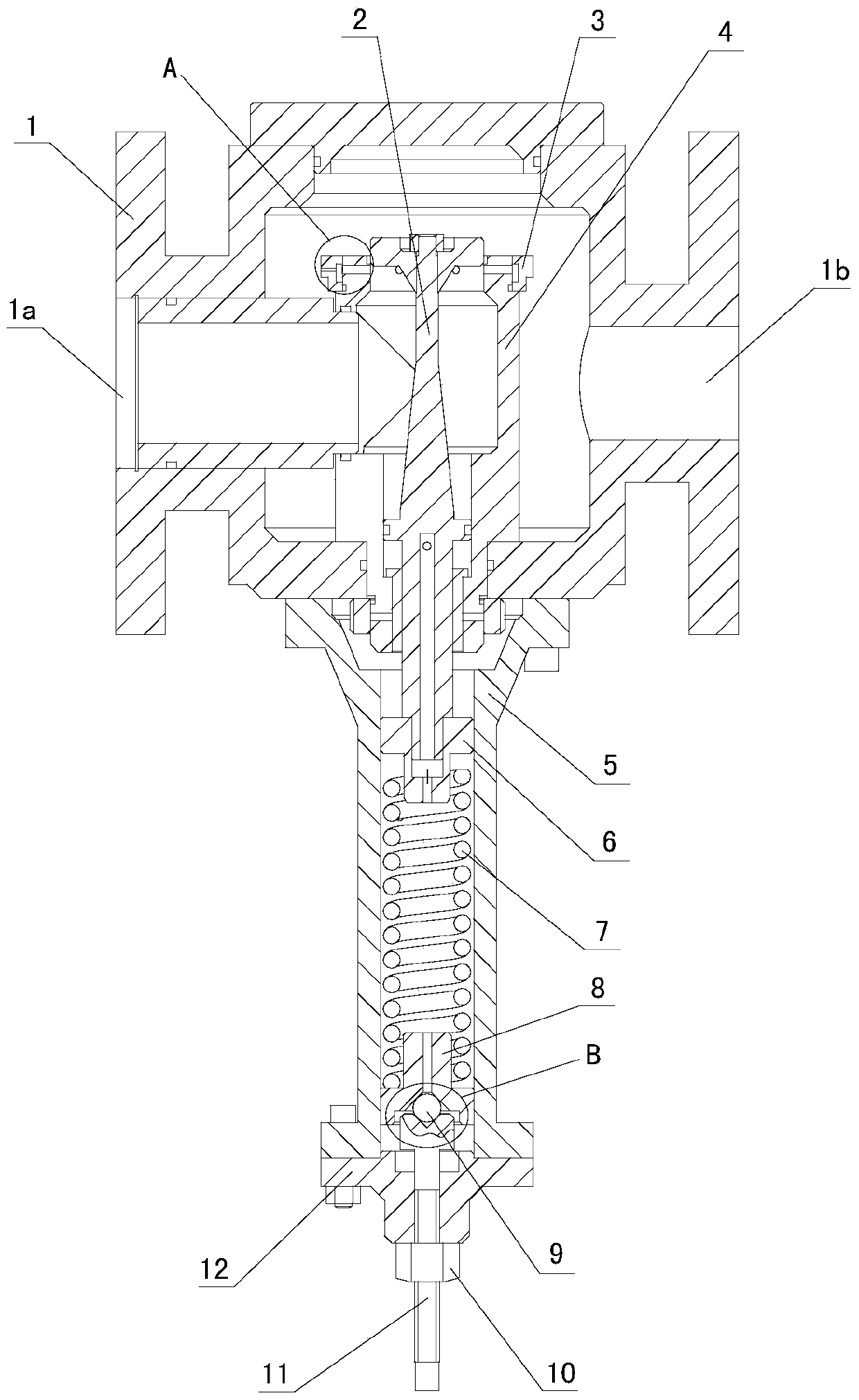

[0011] see figure 1

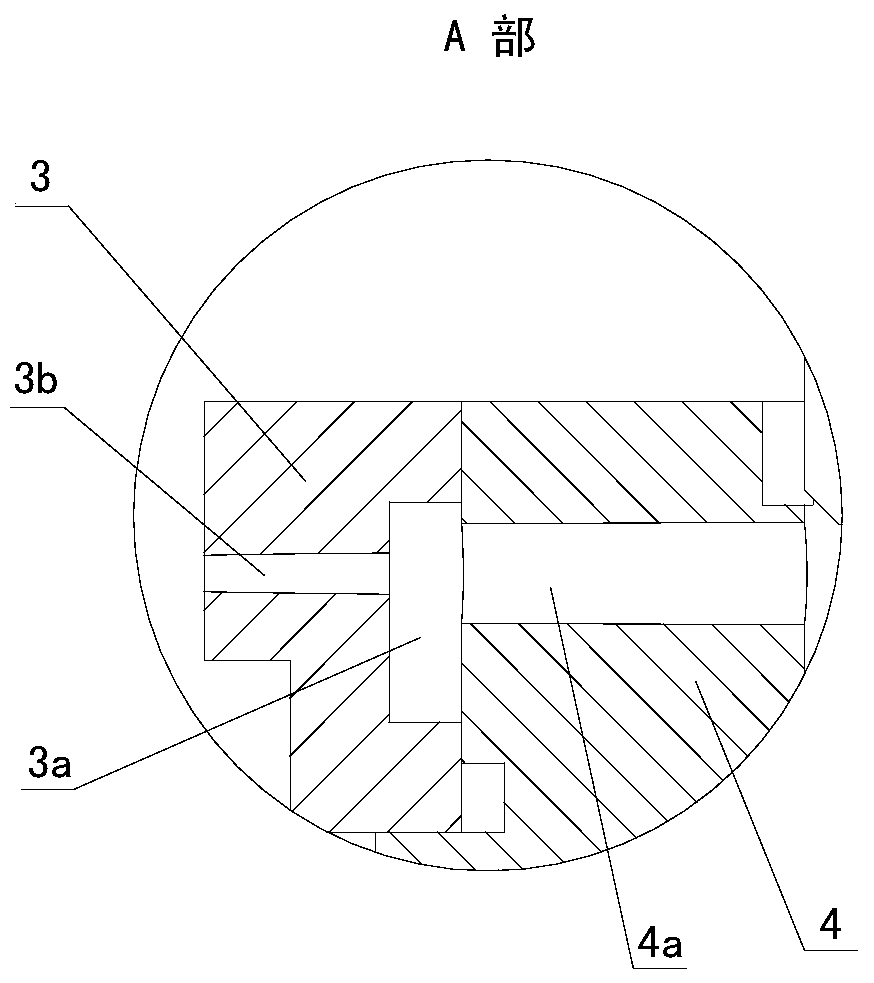

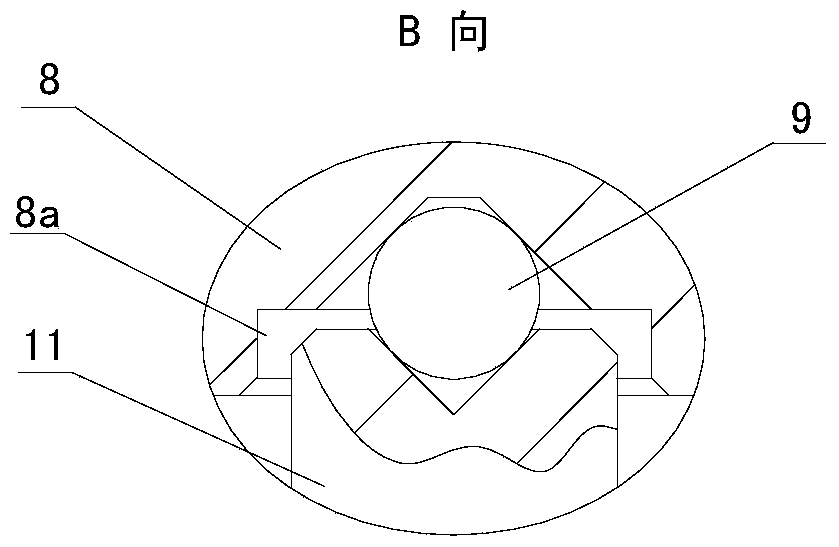

[0012] The valve body 1 of the stepless pressure reducing valve provided by the present invention is provided with a valve seat 4, and the valve body 1 is provided with a water inlet 1a and a water outlet 1b, and the valve seat 4 is equipped with a piston 2 that fits with the gap, and the valve body 1 The bottom is connected with a guide sleeve 5 parallel to the axis of the piston 2. In this embodiment, the guide sleeve 5 is coaxial with the axis of the piston 2. The lower end of the guide sleeve 5 is connected with an end cover 12, and the lower end of the piston 2 extends into the guide sleeve 5. Pass the push rod 11 that is threadedly engaged with it on the cover 12, spring 7 is housed in the guide sleeve 5, the lower end of spring 7 is supported by the upper end of push rod 11, and the upper end of spring 7 is close to the lower end of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com