A foldable hollow board

A technology of empty boards and folded cores, applied in the direction of sheet/board, building elements, etc., can solve the problems of difficulty in ensuring the distance between the middle folding connectors, high manufacturing cost, and high labor intensity, and achieve easy connection and fixation and simple manufacturing , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

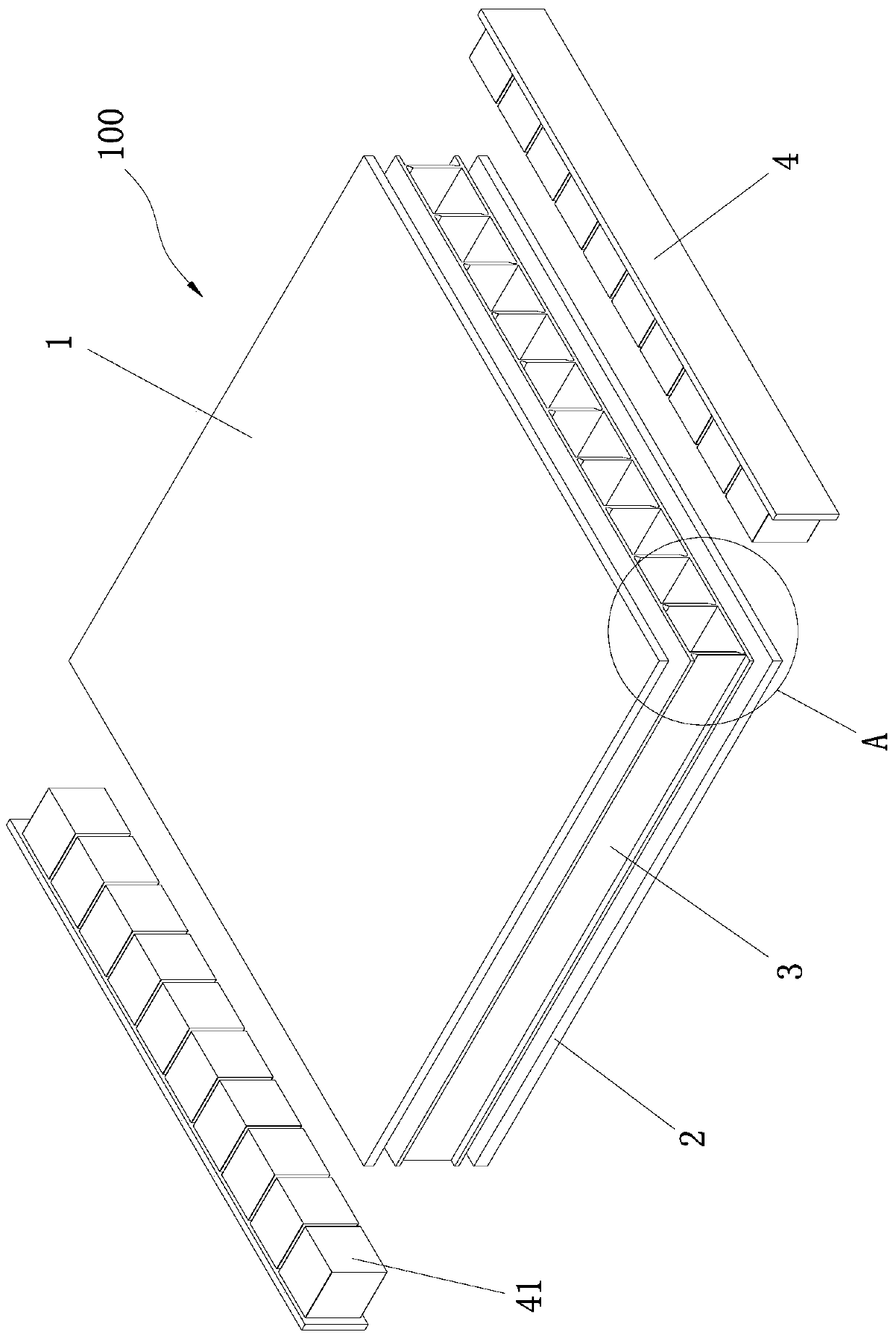

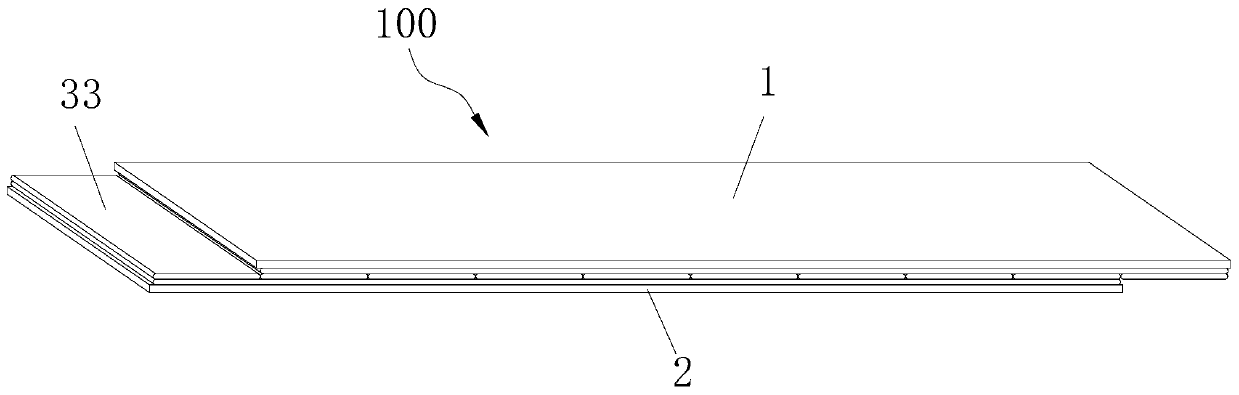

[0027] figure 1 It is an exploded view of the foldable hollow panel in Embodiment 1 of the present invention. like figure 1 As shown, the foldable hollow panel 100 provided in this embodiment includes a panel 1 and a panel 2 , wherein the panel 1 and the panel 2 are parallel, and the panel 1 and the panel 2 are connected by a folding core 3 .

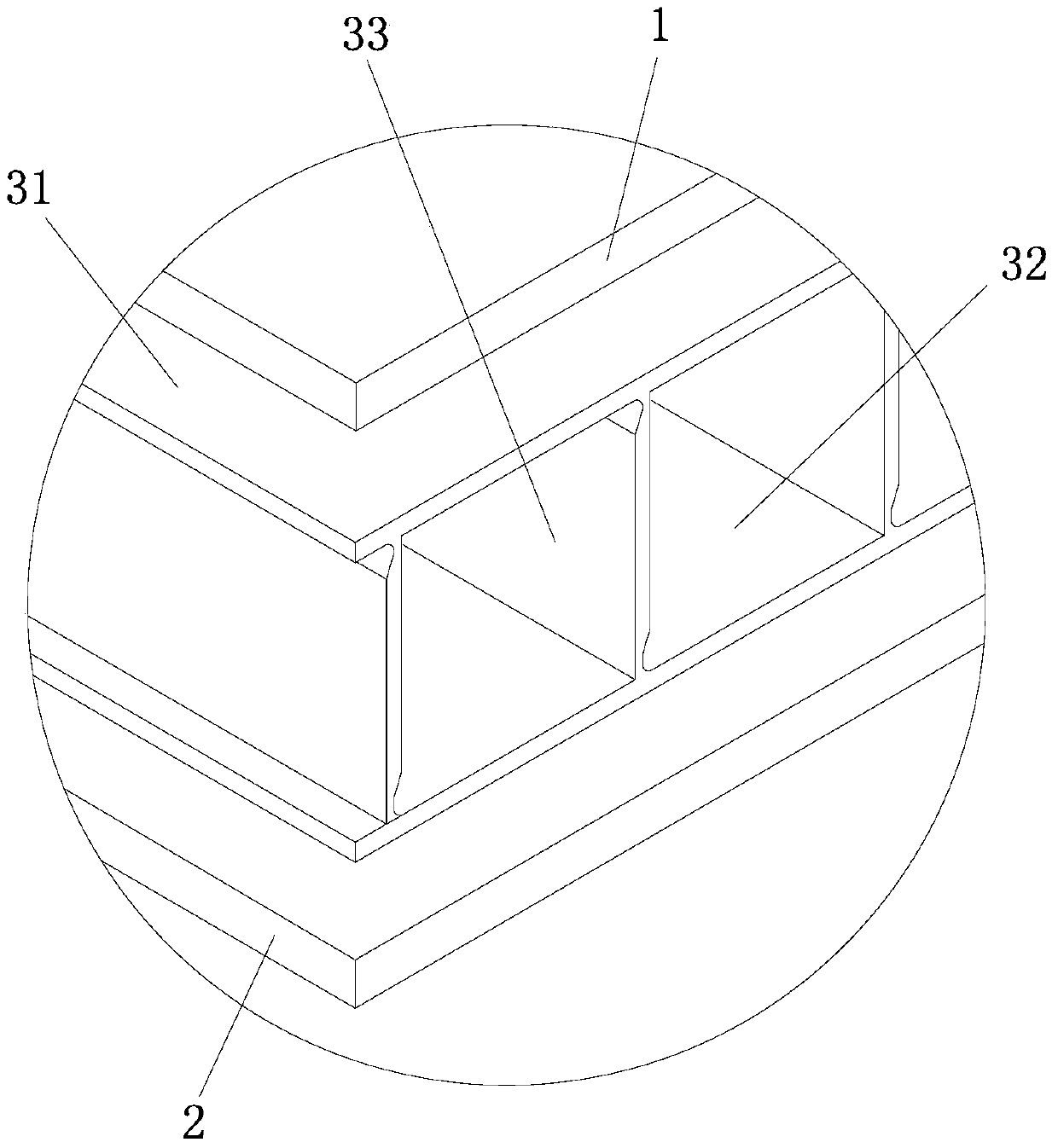

[0028] figure 2 for figure 1 Enlarged view of the part corresponding to the letter A in the figure. like figure 1 and figure 2 As shown, the folded cores 3 each include a parallel substrate 31 and a substrate 32 , and the substrate 31 is attached to the adjacent panel 1 , and the substrate 32 is attached to the adjacent panel 2 .

[0029] Between the base plate 31 and the base plate 32 there are several mutually parallel ribs 33 arranged at equal intervals in sequence, and an edge banding plate 4 perpendicular to the ribs 33 is detachably arranged between the panel 1 and the panel 2 . In this embodiment, the cross section of th...

Embodiment 2

[0037] In this embodiment, the parts that are the same as in the first embodiment are given the same reference numerals, and the same text descriptions are omitted.

[0038] Figure 4 It is a perspective view of the edge banding plate in the second embodiment of the present invention. like Figure 4 As shown, compared with Embodiment 1, the foldable hollow panel provided by this embodiment has the following difference: the inner side wall of the edge sealing plate 5 is provided with several snapping pieces 51 at equal intervals along the length direction, and every two adjacent snapping pieces 51 bite the corresponding single rib plate 33 ( figure 2 shown in ). Moreover, each engaging piece 51 is provided with a U-shaped groove 52 on a surface parallel to the inner side wall. Two engaging parts 53 are respectively formed on the two side walls of the U-shaped groove 52 , and every two adjacent engaging parts 51 engage the ribs 33 embedded in the engaging parts 53 .

Embodiment 3

[0040] In this embodiment, the parts that are the same as those in Embodiment 1 and Embodiment 2 are given the same reference numerals, and the same text descriptions are omitted.

[0041] Figure 5 It is a perspective view of the foldable hollow board in the third embodiment of the present invention. like Figure 5As shown, compared with Embodiment 1, the foldable hollow panel 200 provided by this embodiment has such a structure: it includes a first panel 201, a second panel 202, and a third panel 203. It is important that the first panel 201, The second panel 202 and the third panel 203 are parallel to each other and have the same specification.

[0042] Wherein, the first panel 201 and the second panel 202 are connected by the first folding core 204, the second panel 202 and the third panel 203 are connected by the second folding core 205, the first folding core 204 and the second folding core 205 have the same structure. More importantly, in order to improve the rigidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com