Moisture absorption structure for automobile headlamp

A technology for automobile headlights and lamp bodies, which is applied to parts of lighting devices, lighting devices, fixed lighting devices, etc. And the effect of replacing desiccant, low manufacturing and use costs, reducing service life and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

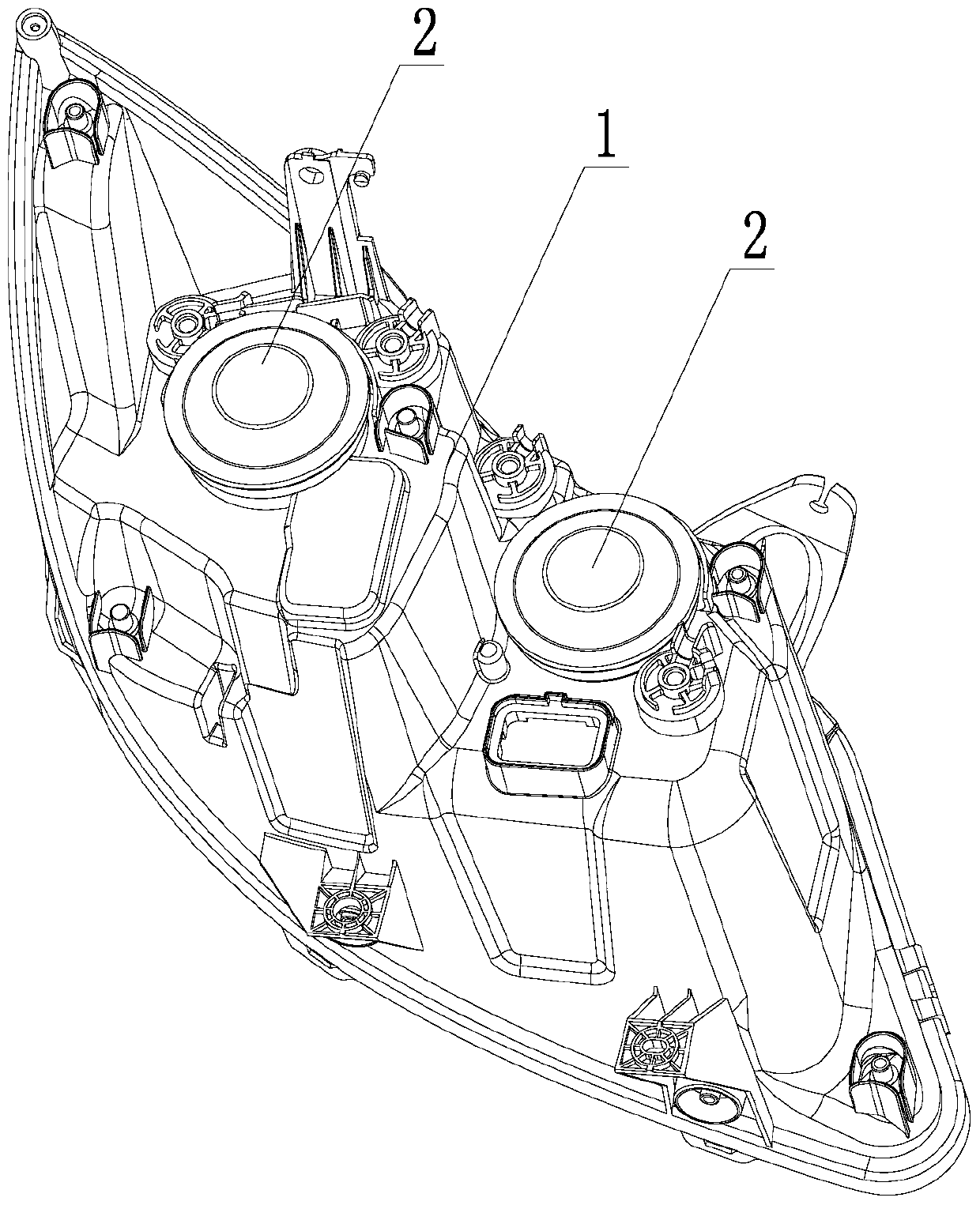

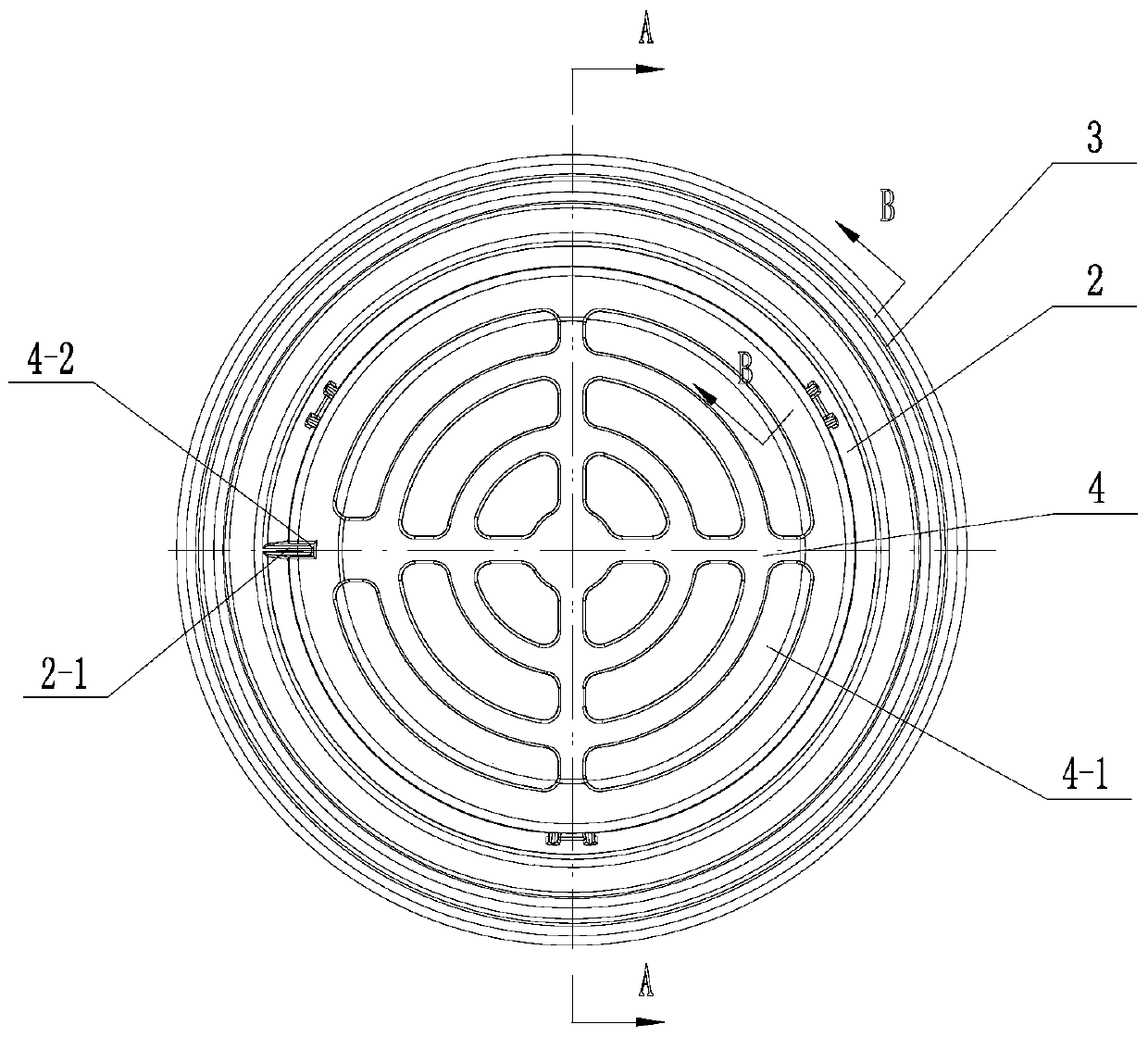

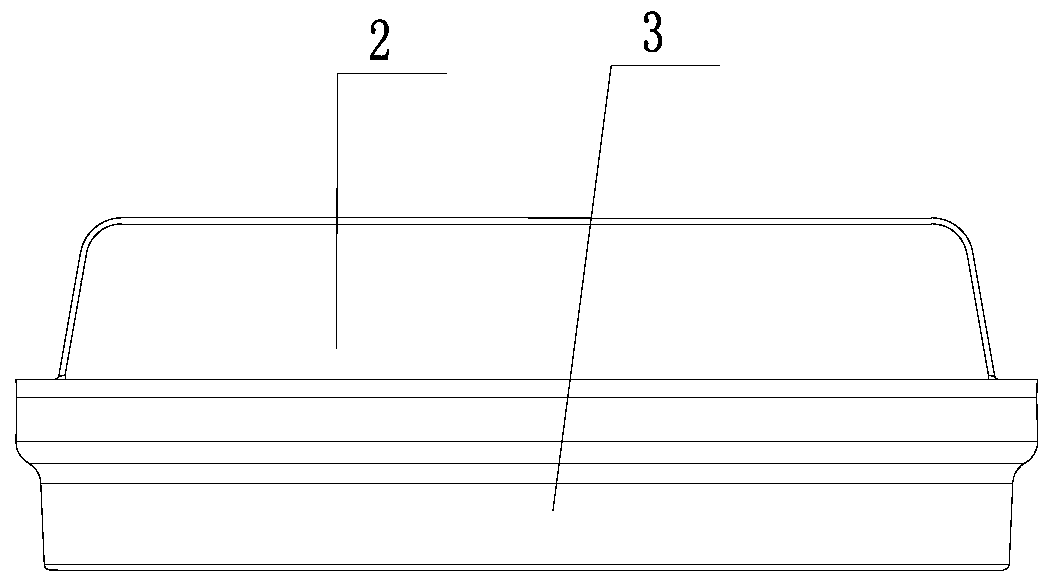

[0016] See figure 1 As shown, the present invention is used in the hygroscopic structure of the automobile headlight, including the lamp body 1, and the rear cover and the cover plate 4 are installed at the rear cover hole of the lamp body 1. See Figure 2-5 shown. The back cover of the present invention includes a connecting ring 3 made of rubber and a cover body 2 with a ring edge made of plastic, and the ring rib 2-3 protruding from the upper end surface of the ring edge of the cover body 2 is crimped to the annular ring of the connecting ring 3 The groove 3-1 is fixedly connected with the connecting ring 3, so that the connecting ring 3 and the cover body 2 can form an integrated structure, and the connecting ring 3 is sealed and connected with the back cover hole on the lamp body 1, so that the back cover is sealed and connected to the lamp body 1 At the back cover hole of the lamp body 1, the connecting ring 3 of the present invention is made of rubber material, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com