Large impact load distribution mechanism

A technology of load distribution and large impact, applied to rocket launchers, offensive equipment, weapon types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

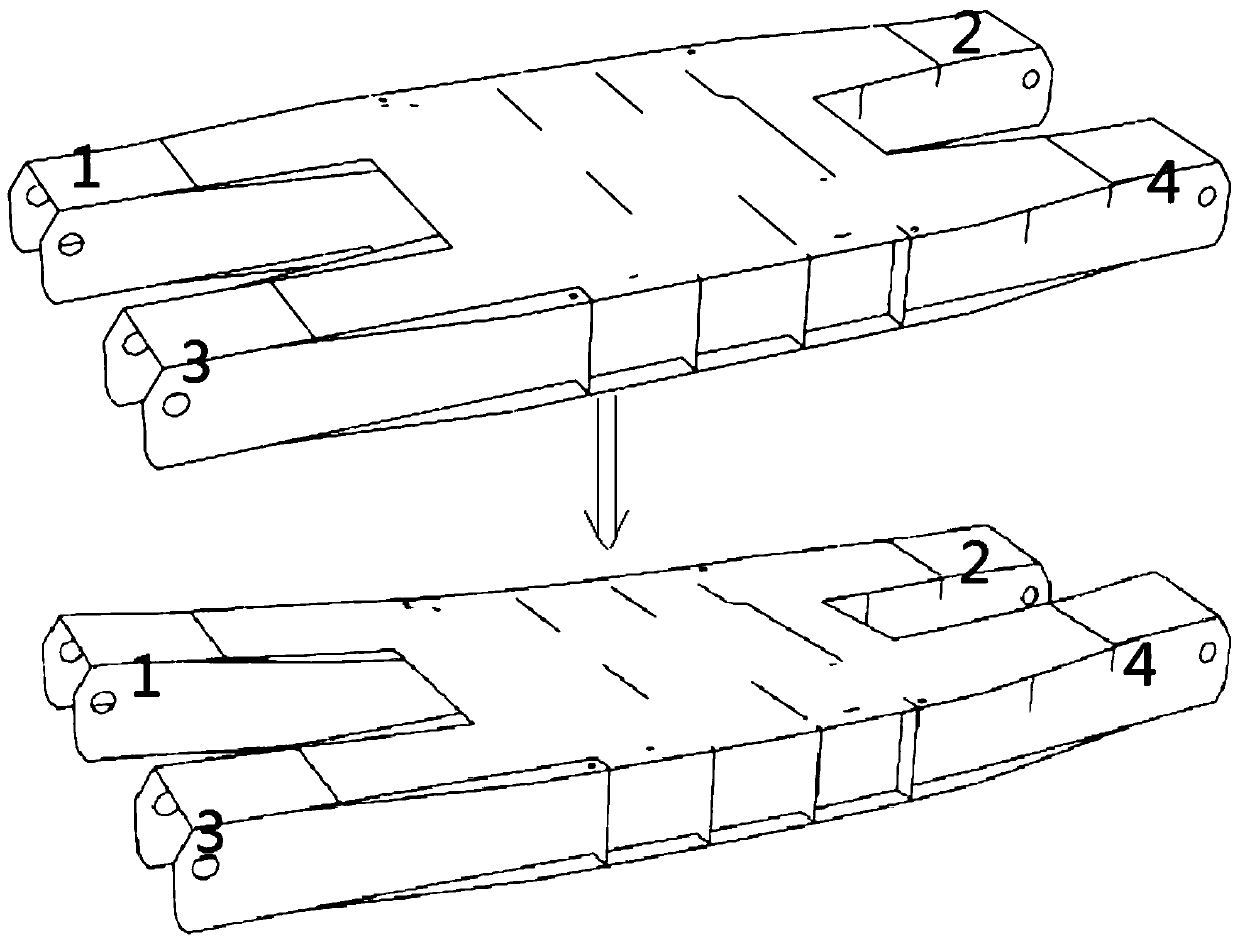

[0021] The present invention will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

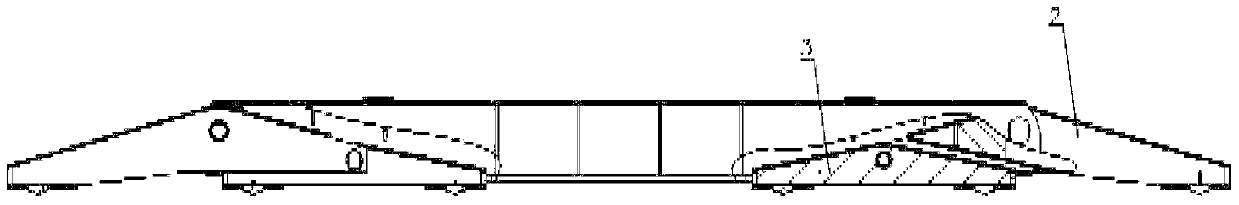

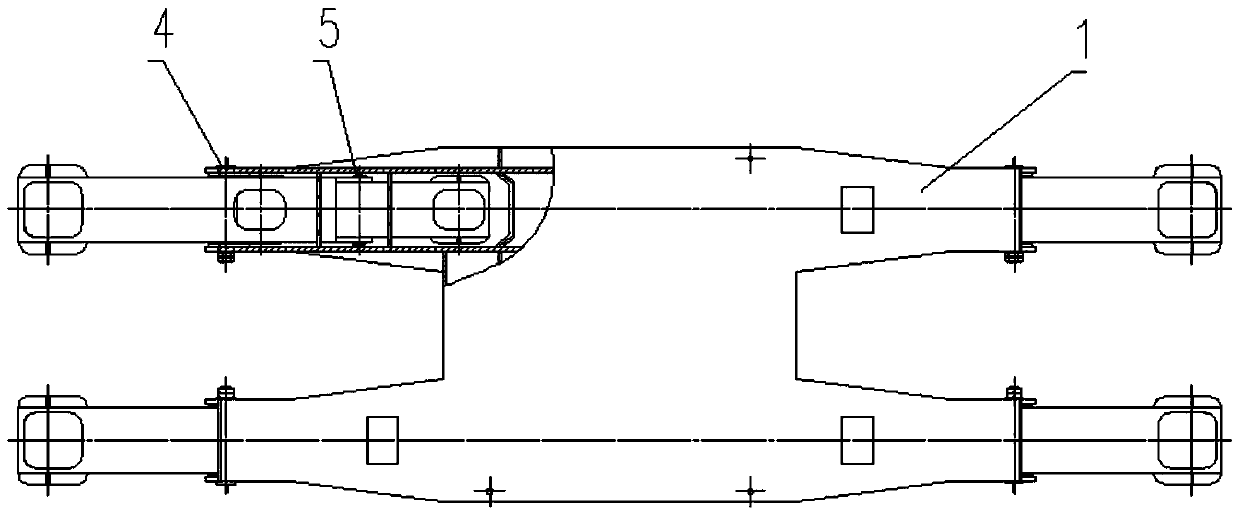

[0022] A large impact load distribution mechanism, which is a large box-shaped welded beam structure, multi-level load beams, each level has multiple load beams; all load beams of the same level are in the same load surface; two adjacent levels The load beams are connected by pin shafts, and the lower load beams share the load of the upper load beams connected with the pin shafts; the upper and lower adjacent two-stage load beams use the pin shafts as fulcrums to form a lever structure.

[0023] It has the function of dispersing and guiding the large impact load carried by the upper part of the product to the lower structure in a specific proportion, thereby reducing the local load of the lower structure and ensuring its service life to meet the launch requirements. The load distribution mechanism needs to meet the high impact bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com