A thermal isolation device for high temperature and high cycle fatigue test

A high-cycle fatigue and testing technology, used in measuring devices, vibration testing, and testing of machine/structural components, etc., can solve problems such as reducing system rigidity, shaking table damage, failing to achieve vibration stress, etc., to meet temperature isolation requirements. requirements, improve long-term effects, avoid the effects of excitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

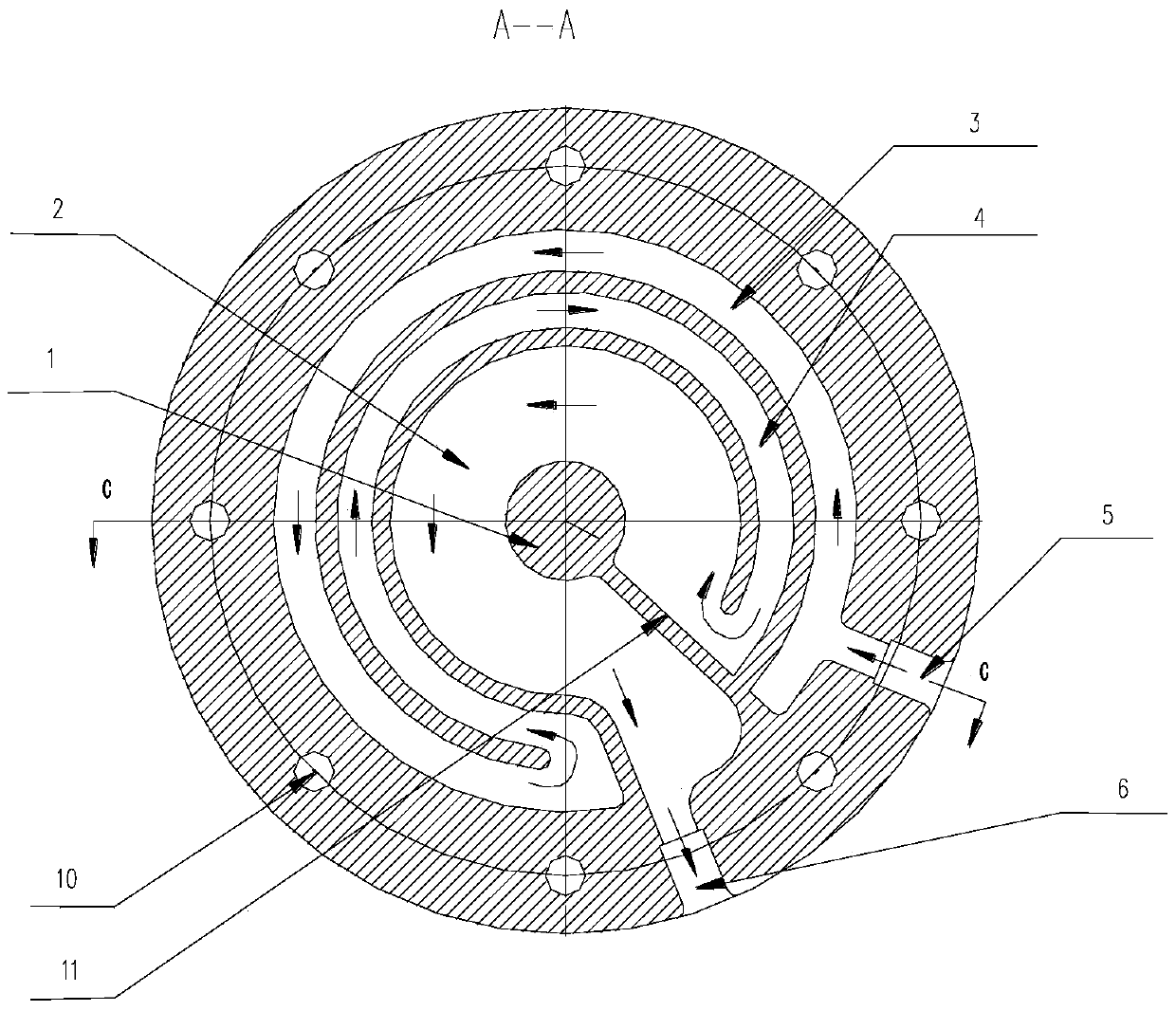

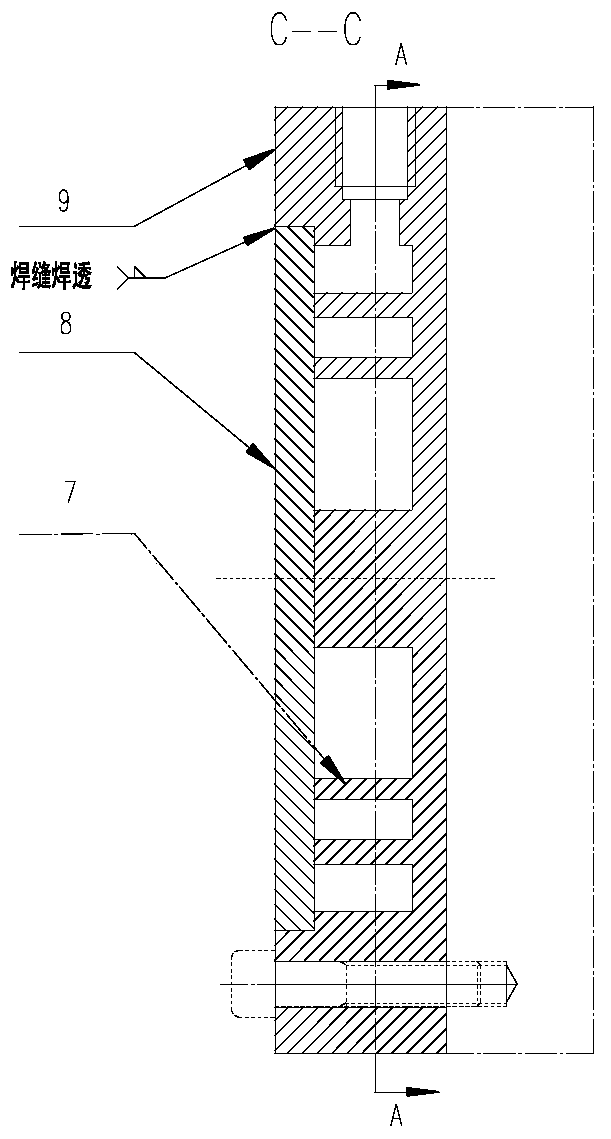

[0008] The present invention will be described in detail below. A heat isolation device for high temperature and high cycle fatigue tests, characterized in that it is composed of a shell 9 and a cover plate 8 welded; There are three arc-shaped cooling water passages on the upper surface of the housing 9, which are respectively from the outside to the inside: the outer runner 3, the middle runner 4 and the inner runner 2, and the inner runner 2 There is a circular central boss 1 in the center of the shell 9, a water inlet 5 and a water outlet 6 are arranged on the outer cylindrical surface of the housing 9, the water inlet 5 communicates with the water inlet end of the outer flow channel 3, and the water outlet of the outer flow channel 3 The end is connected with the water inlet end of the middle flow channel 4, the water outlet end of the middle flow channel 4 is connected with the water inlet end of the inner flow channel 2, the water outlet end of the inner flow channel 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com