Treatment method of machine-made sand tailings and concrete prepared from machine-made sand tailings

A processing method and technology of machine-made sand, applied in the field of building materials, can solve problems such as poor construction performance of concrete, and achieve the effects of reducing concrete cost, realizing waste and solid reuse, and reducing dependence on mineral admixtures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present embodiment provides a kind of processing method of machine-made sand tailings, and this processing method comprises the following steps:

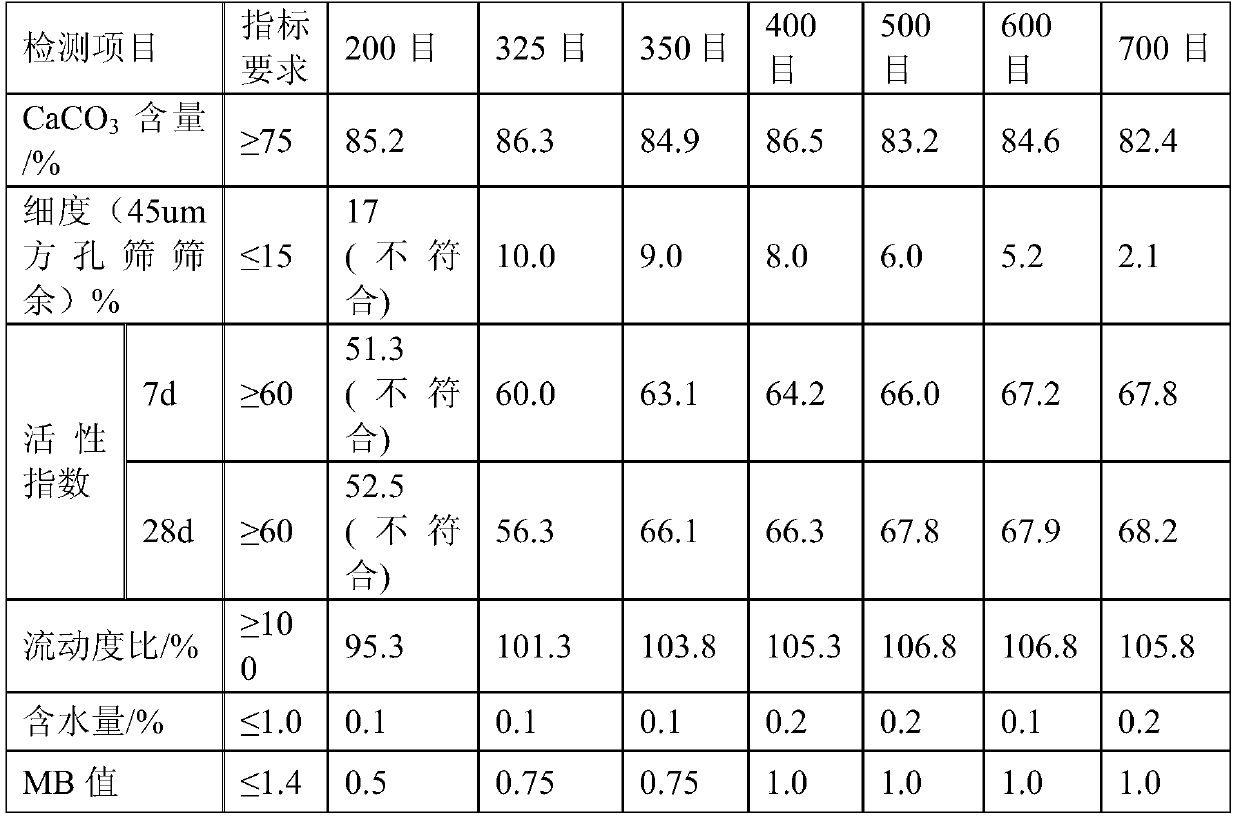

[0031] (1) Collect the machine-made sand tailings, and dry the collected machine-made sand tailings with hot air, so that the water content of the machine-made sand tailings is lower than 1%; the machine-made sand tailings are solids formed during the production of machine-made sand Waste, the calcium carbonate content of the machine-made sand tailings is greater than 75%, and the methylene blue value is not greater than 1%;

[0032] (2) Put the dried machine-made sand tailings into the crusher for crushing, and then grind them until the specific surface area is 600m 2 / kg.

[0033] This embodiment also provides a kind of concrete. The machine-made sand tailings obtained by the above-mentioned treatment method are used as raw materials. The concrete is specifically composed of the following raw materials in parts by weig...

Embodiment 2

[0038] The present embodiment provides a kind of processing method of machine-made sand tailings, and this processing method comprises the following steps:

[0039] (1) Collect the machine-made sand tailings, and dry the collected machine-made sand tailings with hot air, so that the water content of the machine-made sand tailings is lower than 1%; the machine-made sand tailings are solids formed during the production of machine-made sand Waste, the calcium carbonate content of the machine-made sand tailings is greater than 75%, and the methylene blue value is not greater than 1%;

[0040] (2) Put the dried machine-made sand tailings into a crusher for crushing, and then grind until the particle size is 500 mesh and the fineness is not more than 10%.

[0041]This embodiment also provides a kind of concrete. The machine-made sand tailings obtained by the above-mentioned treatment method are used as raw materials. The concrete is specifically composed of the following raw materia...

Embodiment 3

[0046] The present embodiment provides a kind of processing method of machine-made sand tailings, and this processing method comprises the following steps:

[0047] (1) Collect the machine-made sand tailings, and dry the collected machine-made sand tailings with selected powder, so that the water content of the machine-made sand tailings is lower than 1%; the machine-made sand tailings are formed during the production of machine-made sand Solid waste, the calcium carbonate content of the machine-made sand tailings is greater than 75%, and the methylene blue value is not greater than 1%;

[0048] (2) Put the dried machine-made sand tailings into a crusher for crushing, and then grind until the particle size is 400 mesh, and the fineness is not more than 10%.

[0049] This embodiment also provides a kind of concrete. The machine-made sand tailings obtained by the above-mentioned treatment method are used as raw materials. The concrete is specifically composed of the following ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com