Method for remotely monitoring and predicting fault of forklift loader

A fault monitoring and fault prediction technology, applied in program control, electrical test/monitoring, test/monitoring control system, etc., can solve the problem of not being able to understand the fatigue degree of forklift truck components in time, lack of fault monitoring and prediction methods, and intelligent level It can improve the efficiency of troubleshooting and save the time of troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

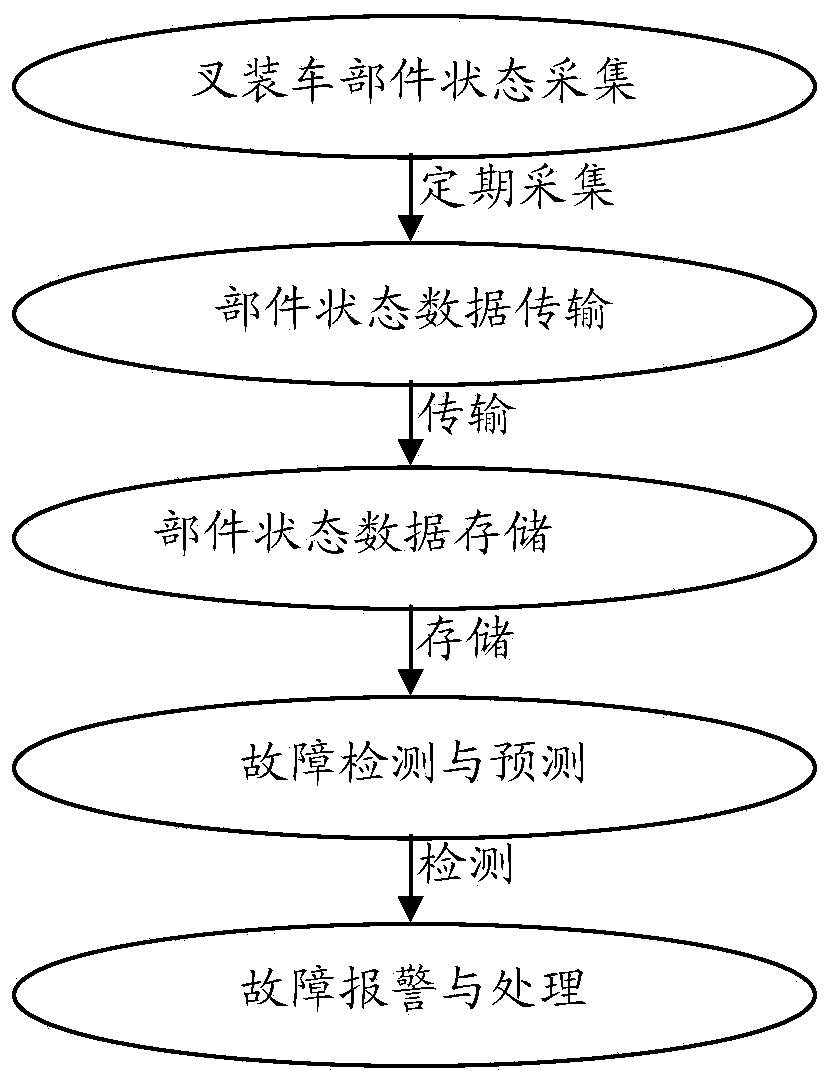

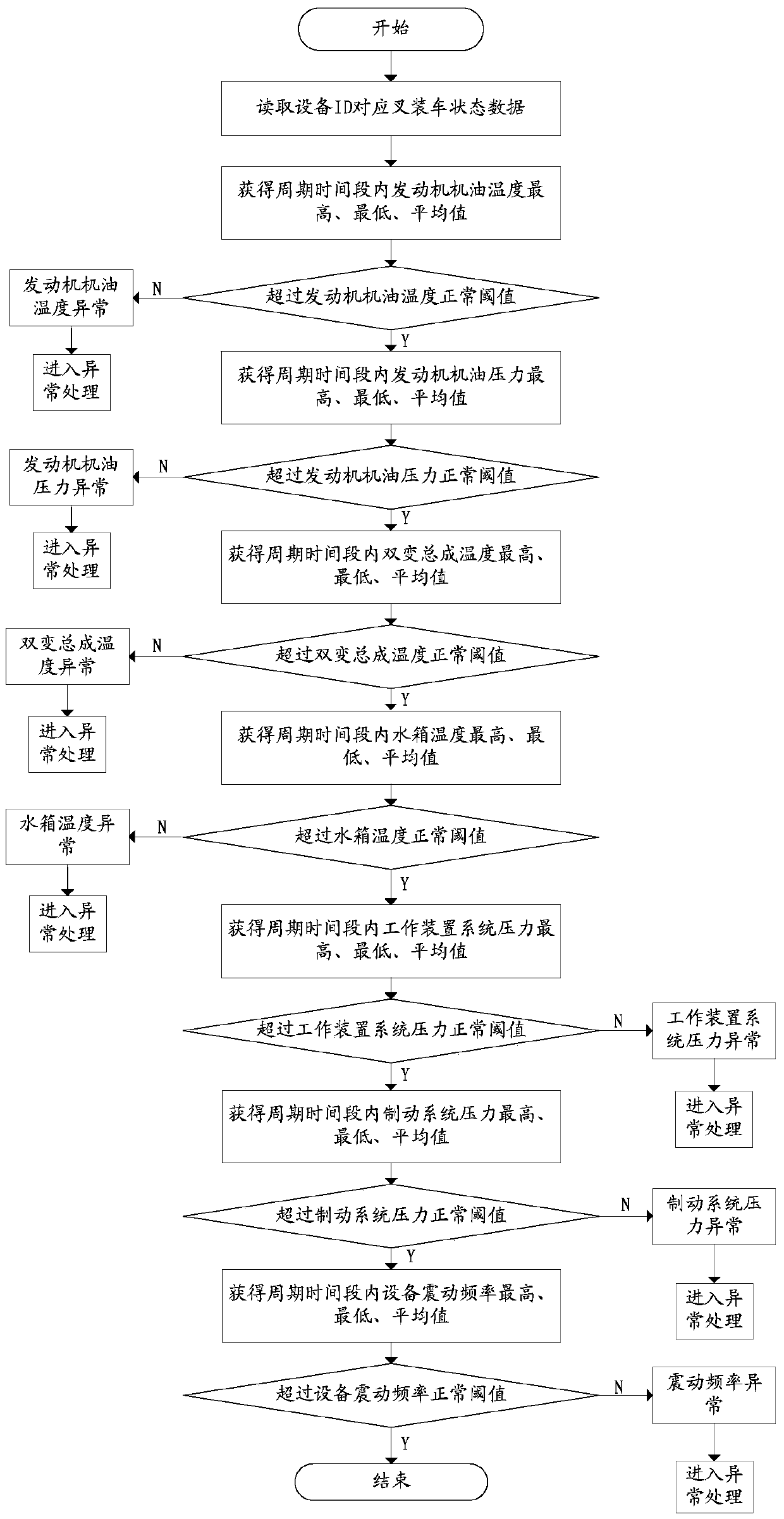

[0042] see Figure 1 to Figure 5 As shown, the present invention is a method for remote fault monitoring and prediction of a forklift truck, which is especially used for forklift trucks in stone mines. The method is as follows:

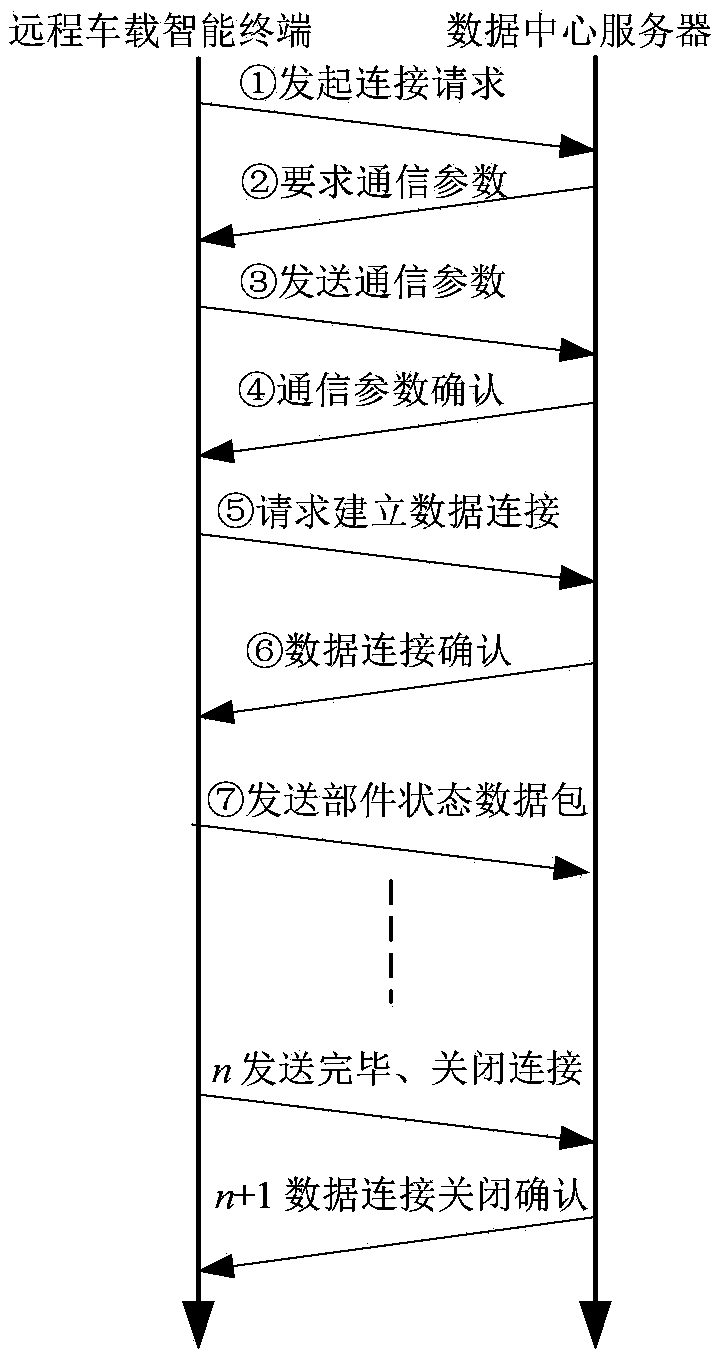

[0043] Forklift trucks working in remote areas are equipped with vehicle-mounted intelligent terminal equipment, which is connected to sensor devices such as pressure sensors, temperature sensors, vibration sensors, and current / voltage sensors on forklift truck components, and regularly collects component status information sensed by the sensors , the conversion circuit converts the collected digital signal and analog signal into data that can be stored by the computer, and according to the data format negotiated with the data center server in advance, the collected data is divided into component status data packets, and attached Information such as the current system time information and the serial number of the vehicle-mounted intelligent terminal e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com