Electronic device testability modeling evaluation method

A kind of electronic equipment and testability technology, applied in the direction of electrical digital data processing, error detection/correction, instruments, etc., can solve the problems of rough processing, inconvenient testability prediction evaluation, low accuracy of testability simulation evaluation results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

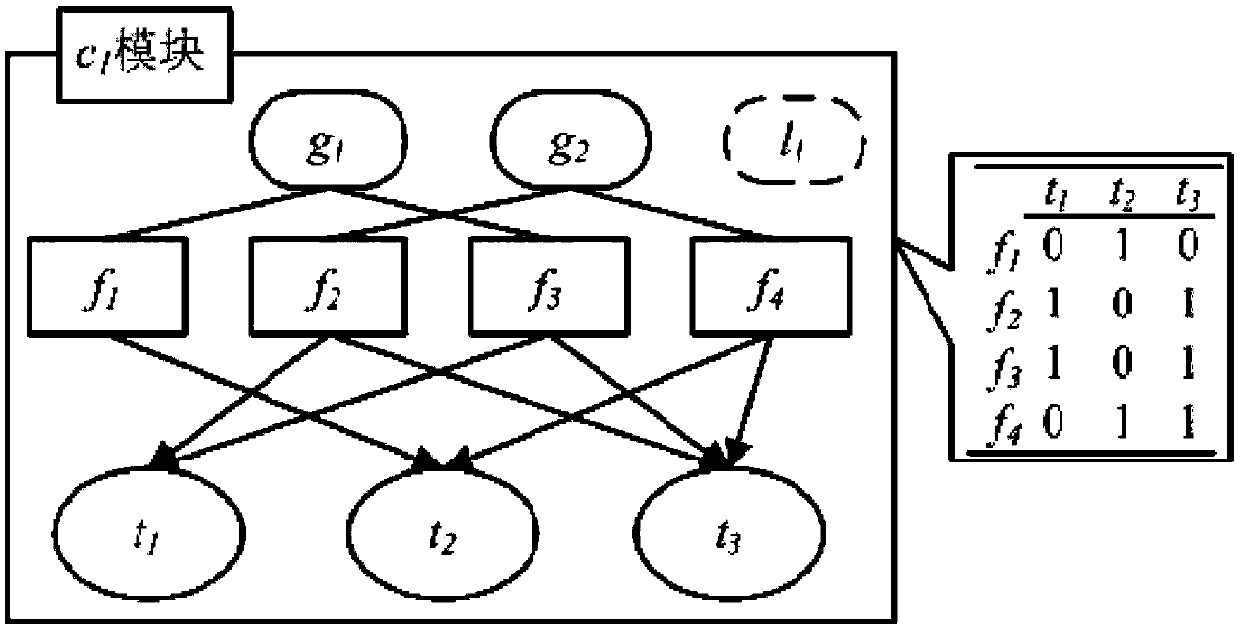

[0098] A system consists of two functional modules c 1 and c 2 Composed of a total of f 1 ,f 2 ,f 3 ,f 4 ,f 5 ,f 6 and f 7 etc. 7 failure modes, designed t 1 ,t 2 ,t 3 ,t 4 ,t 5 and t 5 Wait for 5 tests. Functional module c built according to the testable layered hybrid modeling method 1 A model fragment such as figure 1 shown. The functional block has 4 failure modes f 1 ,f 2 ,f 3 and f 4 , corresponding to 3 tests t 1 ,t 2 and t 3 .

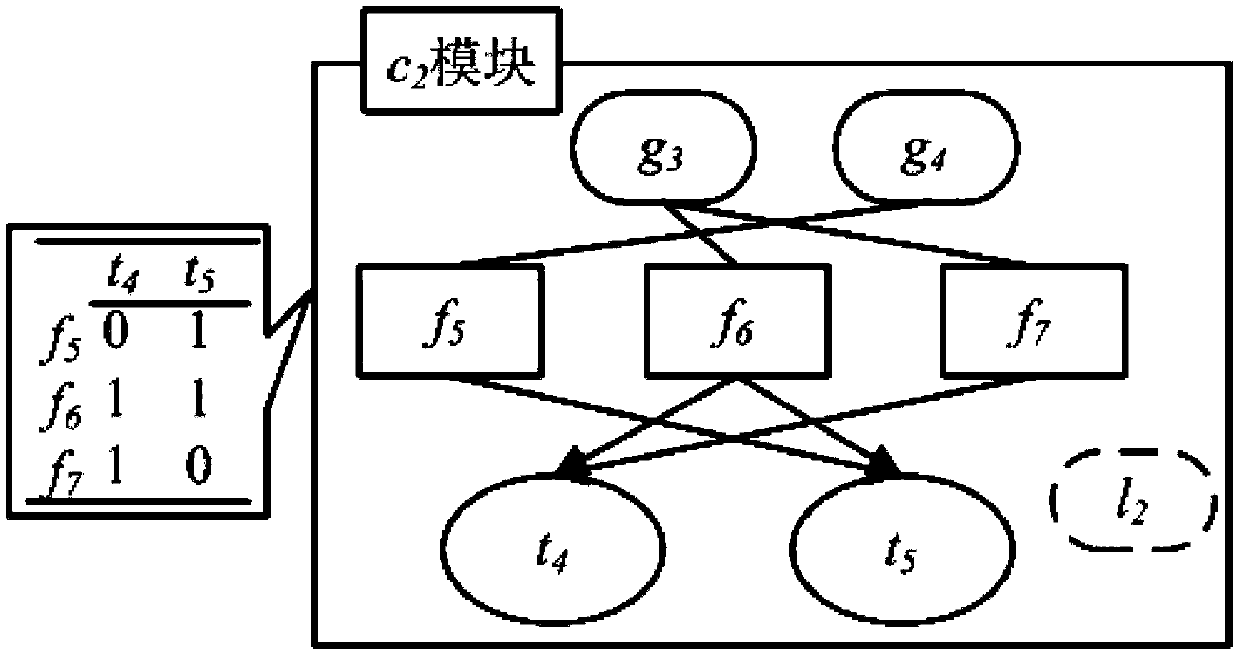

[0099] Functional module c built according to the testable layered hybrid modeling method 2 A model fragment such as figure 2 shown. The functional block has 3 failure modes f 5 ,f 6 and f 7 , corresponding to 2 tests t 4 and t 5 .

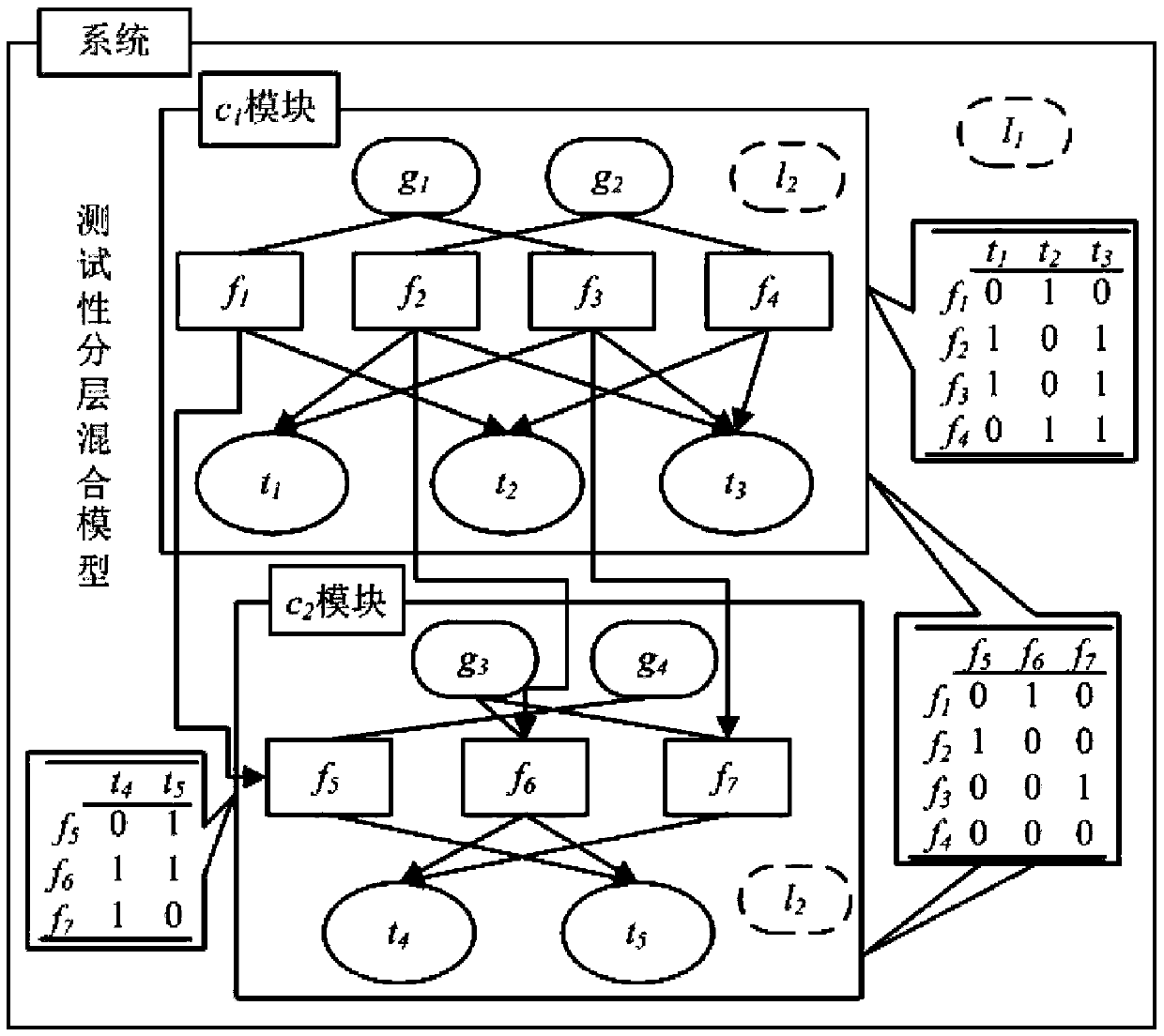

[0100] After the model fragments of each functional module are established, connect the model fragments according to the module association relationship and fault propagation relationship, and establish a testable layered hybrid model of the entire system, as shown in image 3 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com