High-efficiency unmanned aerial vehicle group power inspection system

A power inspection and unmanned aerial vehicle technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as failure to find faults, insufficient battery life, weak anti-interference ability, etc., to overcome narrow image range, improve inspection efficiency, The effect of improving battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention more clear, detailed steps and detailed structures will be provided in the following description, so as to explain the technical solution of the present invention.

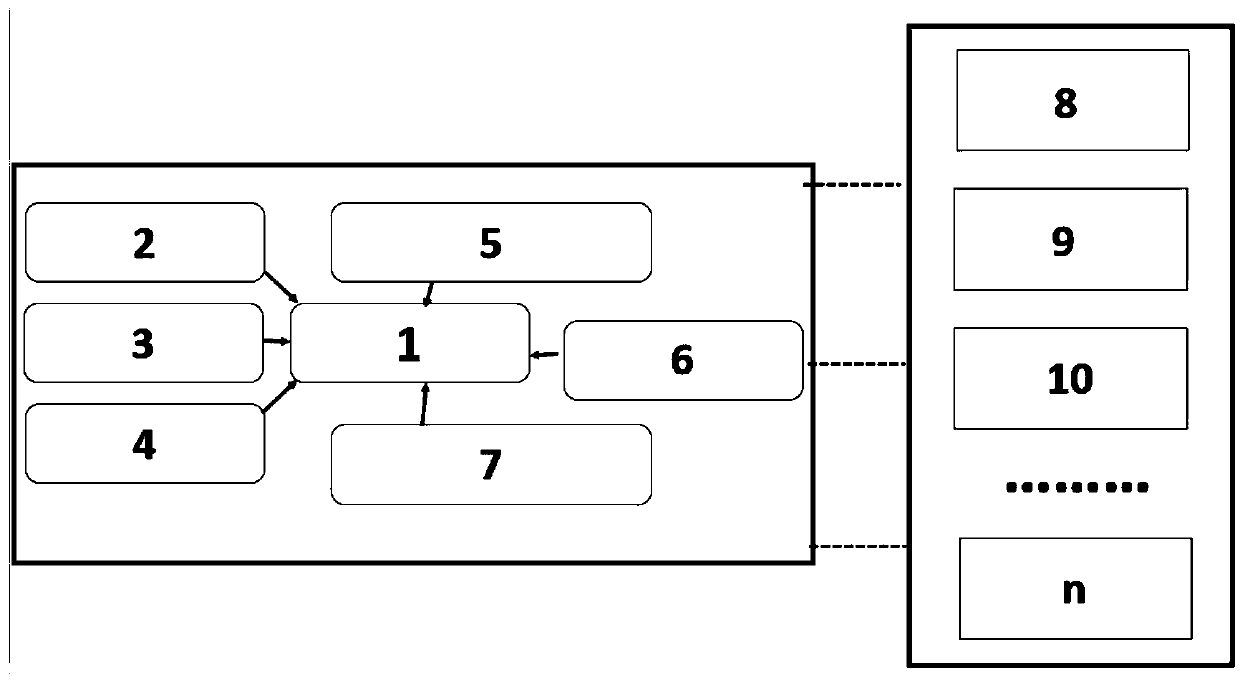

[0029] Such as figure 1 As shown, the high-efficiency UAV swarm power inspection system provided by the present invention mainly includes: a light manned helicopter main body 1, a plurality of multi-rotor UAV complete machines 8 with rotor protection covers, an inspection data processing platform 2, multiple Rotor UAV swarm control platform 4, multi-rotor UAV swarm status monitoring platform.

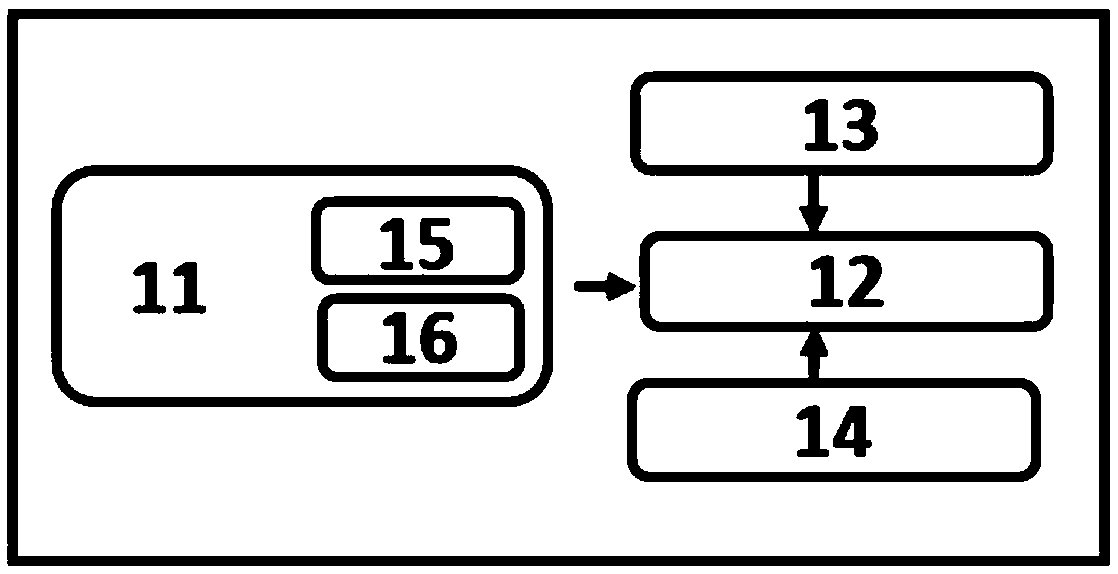

[0030] Such as figure 2 As shown, the multi-rotor UAV is provided with a high-definition surveillance camera 14, an infrared thermal imager 13, an aircraft data transmission station 15, and an aircraft image transmission station 16.

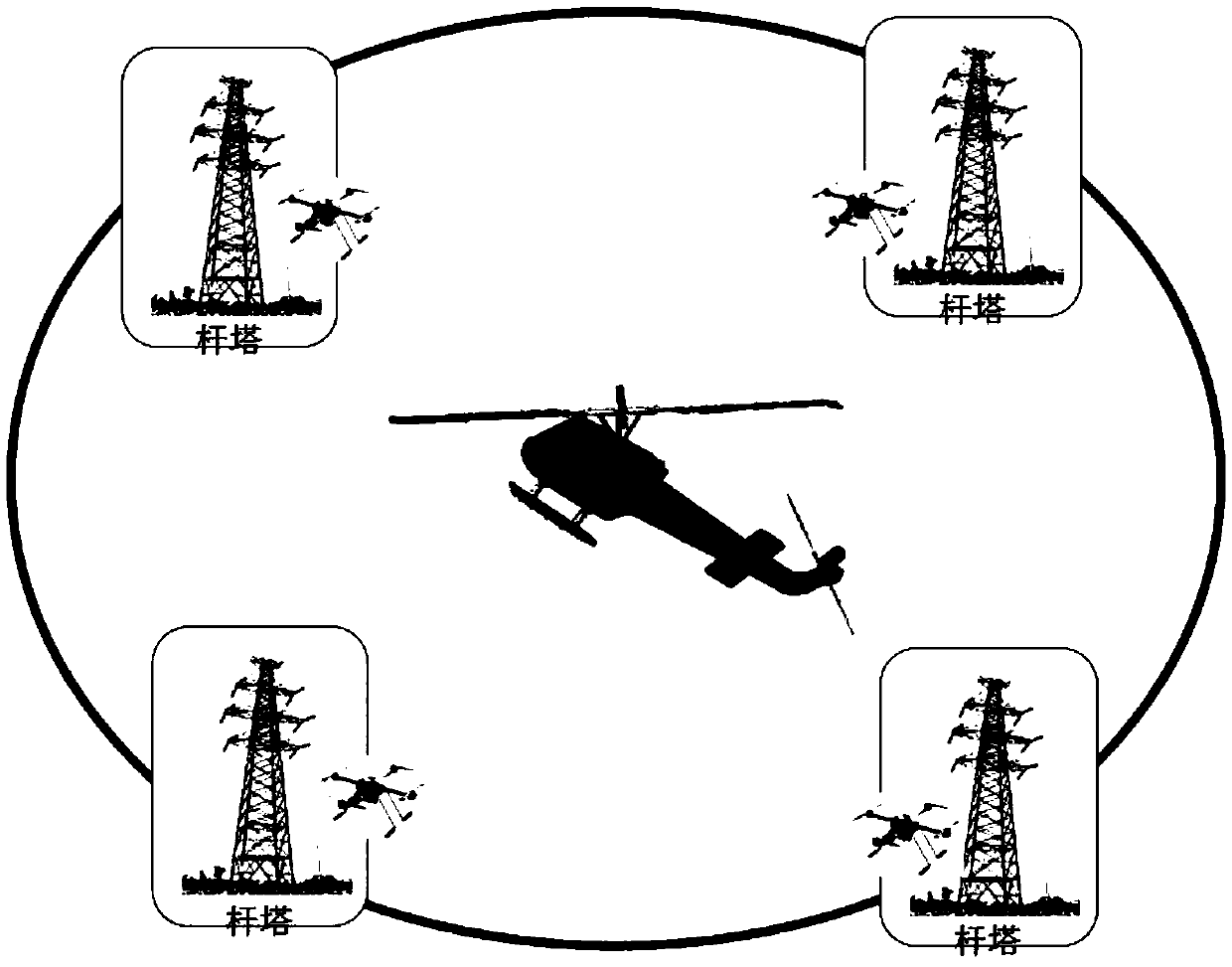

[0031] Such as image 3 As shown, the high-efficiency unmanned aerial vehicle swarm power in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com