Shell and preparation method thereof and electronic device employing same

A shell and matrix technology, applied in the field of shell and its preparation, can solve the problems of not being able to present the texture, difficult to attract consumers' attention, and weak visual effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

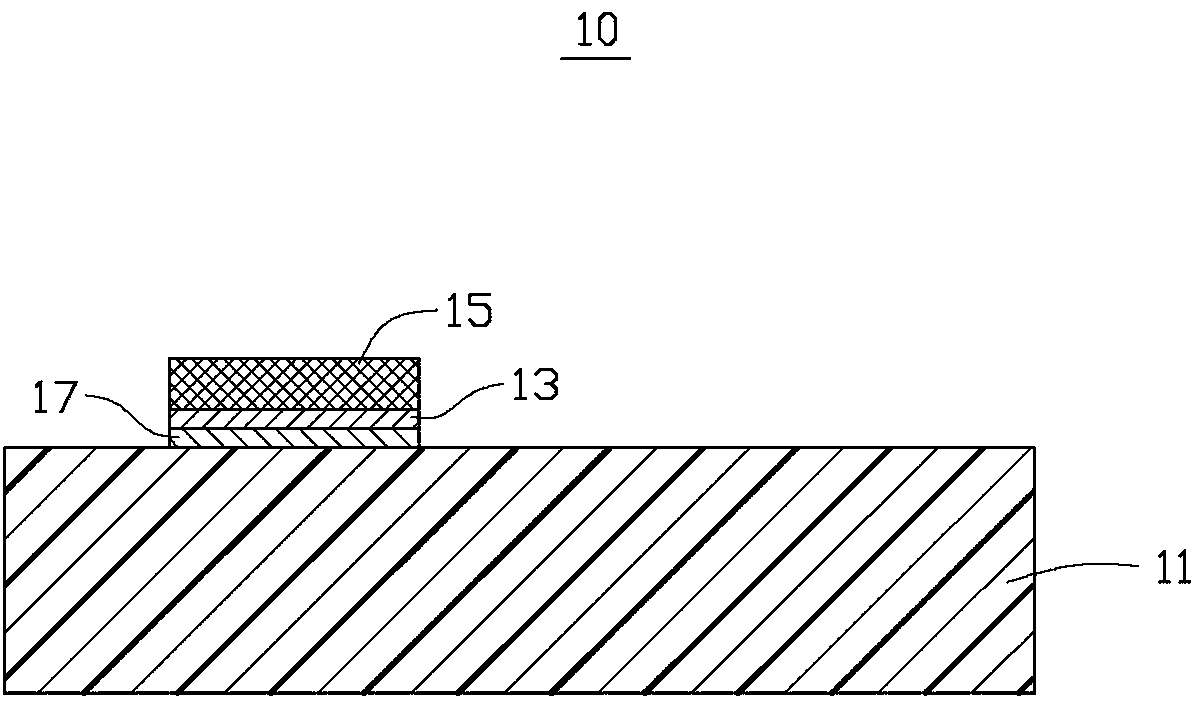

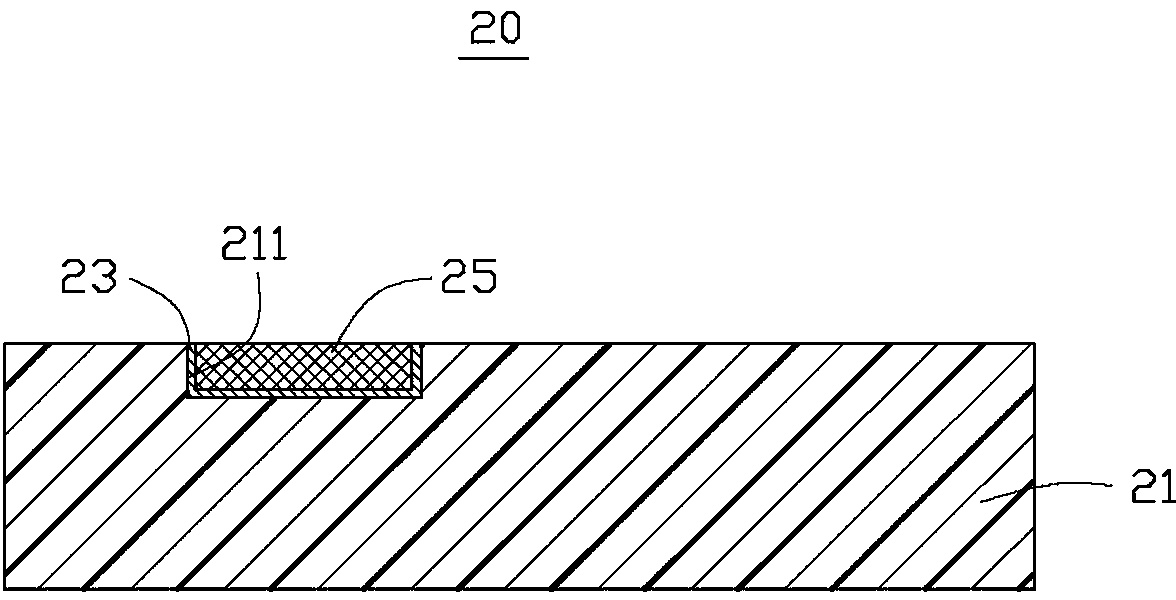

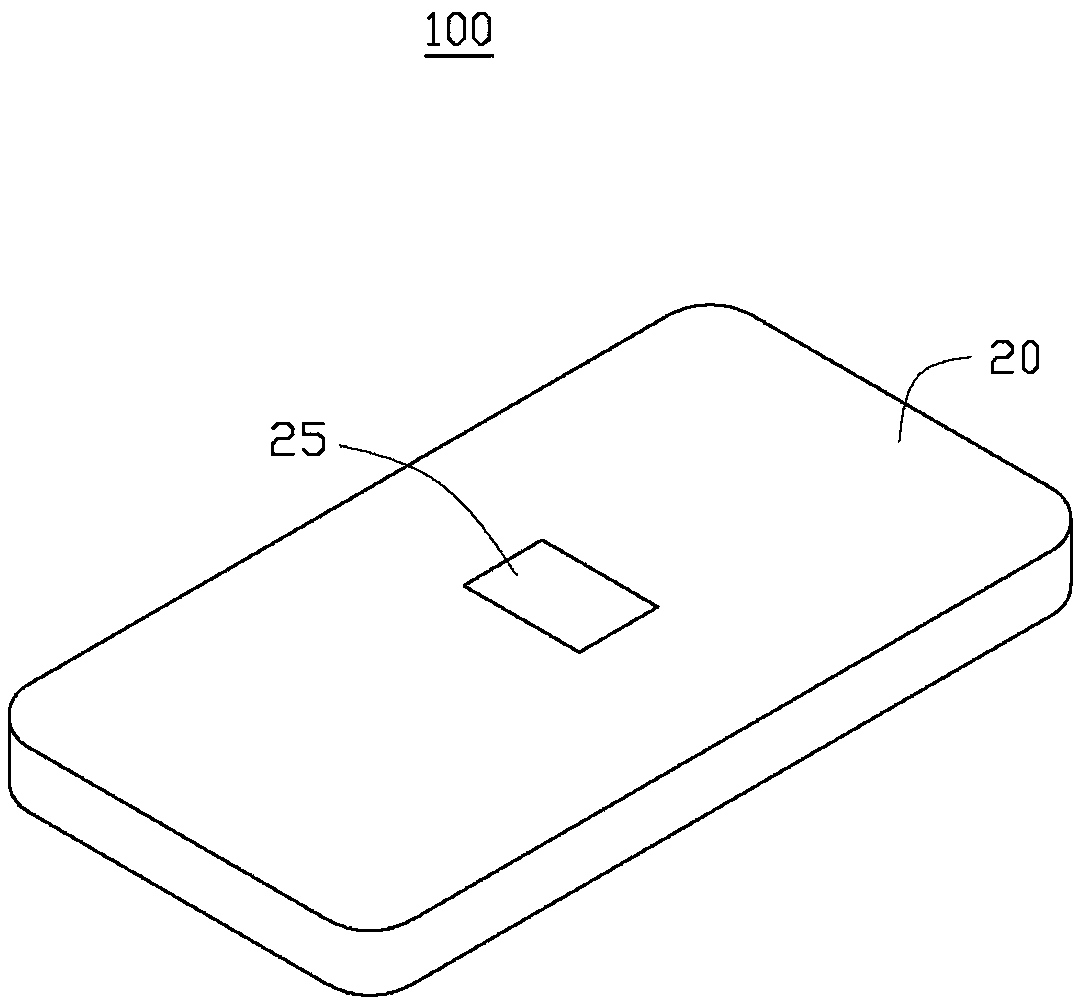

[0017] see figure 1 The casing 10 of the first preferred embodiment of the present invention includes a substrate 11 and a ceramic layer 15, and a film layer 13 is directly bonded to one surface of the ceramic layer 15, and the film layer 13 is sandwiched between the ceramic layer 15 and the substrate 11. between the ceramic layer 15 and the substrate 11 .

[0018] The ceramic layer 15 is a decorative pattern layer or a Logo (logo) layer. The thickness of the ceramic layer 15 is 0.2-5 mm. The material of the ceramic layer 15 can be various ceramic materials used in the prior art, and the ceramic layer 15 can be white or colored.

[0019] The film layer 13 can be formed on the surface of the ceramic layer 15 by conventional thin film forming methods, such as chemical deposition, sputtering, vapor deposition, printing and firing, and the like. The membrane layer 13 is firmly combined with the ceramic layer 15 . In this embodiment, the film layer 13 covers the entire surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com