A staple cartridge assembly of a cutting stapler

A stapler and staple technology, which is applied in the field of medical devices, can solve problems such as poor suture effect, and achieve the effect of simple structure, perfect suture, and no tearing of the incision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

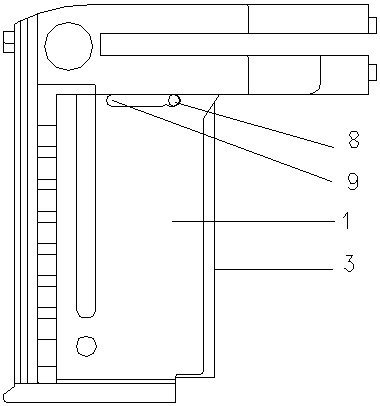

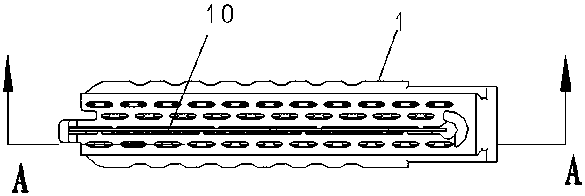

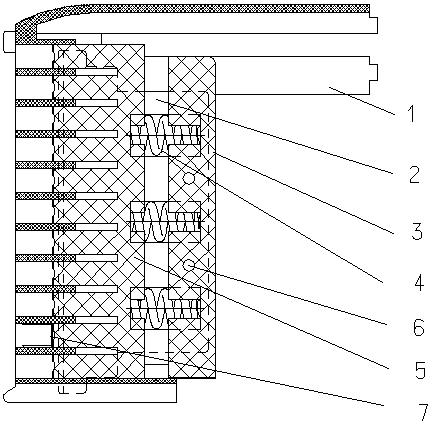

[0013] Such as Figure 1-Figure 3 As shown, a staple cartridge assembly of a cutting stapler includes a staple cartridge 1, a staple pusher 5 and a cutting knife 2 installed inside the staple cartridge 1, and the cutting knife 2 is fixed through the knife groove 10 in the middle of the staple pusher 5 On the cutting knife fixed plate 3, several springs 4 with pre-tightening force are installed between the nail pushing plate 5 and the cutting knife fixing plate 3, and the cutting knife 2 blades are lower than the nail pushing plate 5 tooth surfaces.

[0014] During the assembly process, a component consisting of a nail pusher and the like is inserted into the staple cartridge, and the movement between the two is limited by the boss 8 on the component and the long groove 9 on the staple cartridge. A number of staples 7 are installed into the nail groove of the staple cartridge from the left end shown in the figure, and contact with the nail pusher 5 teeth inserted from the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com