A kind of buckwheat shelling process using buckwheat shelling device

A buckwheat and process technology, applied in the field of buckwheat hulling technology, can solve the problems of low buckwheat hulling rate and broken buckwheat kernels, and achieve the effects of ensuring continuity and uniformity, complete grain shape and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0073] The invention provides a new buckwheat shelling process comprising the following steps:

[0074] Buckwheat moistening

[0075] Buckwheat shelling solution: ethanol 9%, NAHCO3 5%, 3% sodium chloride. Prepare an aqueous solution after mixing the above-mentioned substances, adjust the temperature of the mixed solution at 40 degrees, put the buckwheat in a closed container, and process the buckwheat to be processed by high-pressure spraying, keep stirring slowly during the spraying process, and process 300 kilograms of buckwheat in each batch. 4 minutes each treatment, keep 25 minutes after treatment, the aqueous solution consumption is 0.6% of buckwheat weight;

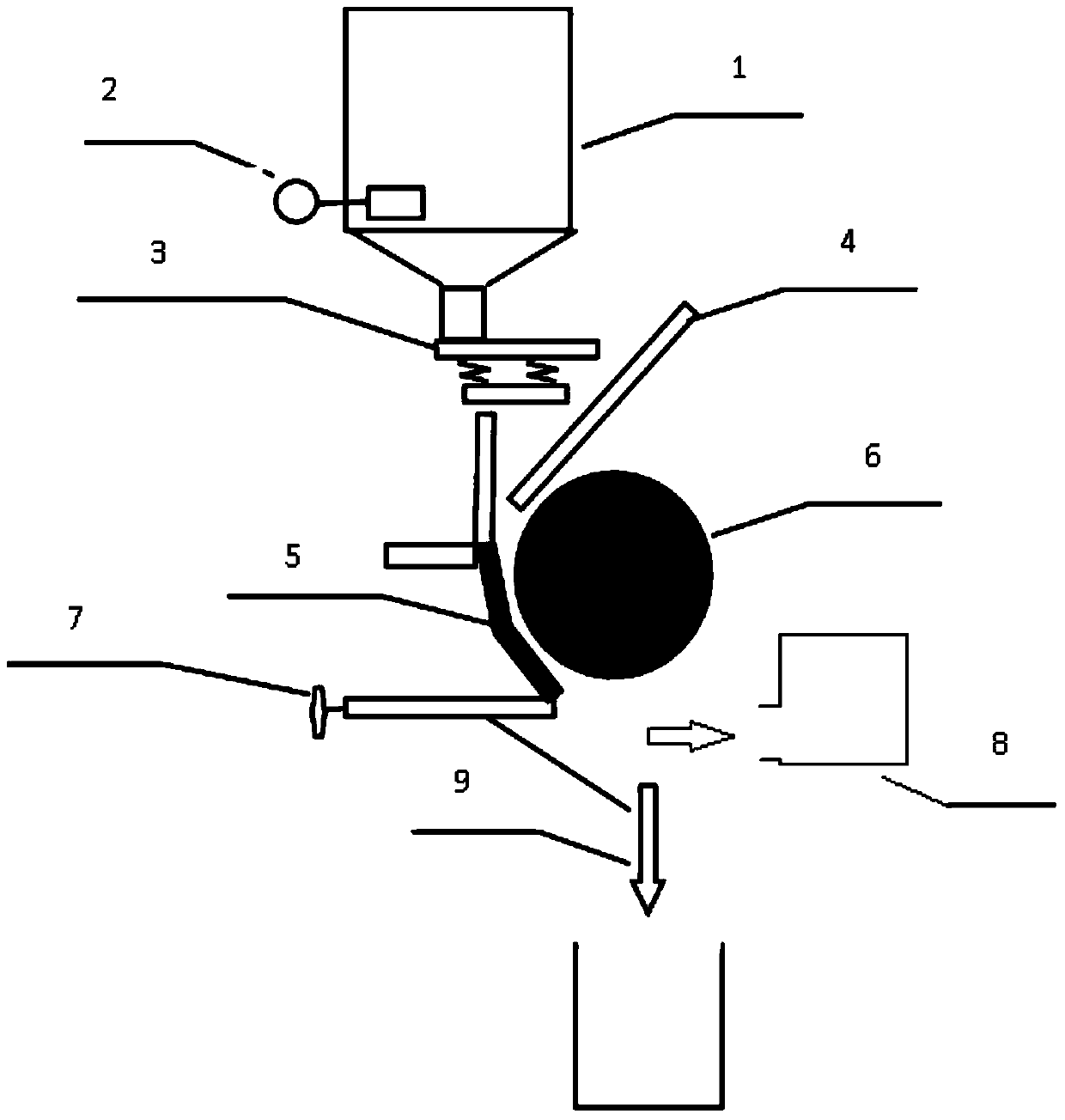

[0076] The buckwheat after wetting treatment is added to the buffer silo, and enters the vibrating feeder and material guide plate through the feed port; through the material guide plate, it enters the shelling studio composed of peeling rubber rollers and shelling sand board devices, and is connected to the sand...

example 3

[0079]The invention provides a new buckwheat shelling process comprising the following steps:

[0080] Buckwheat moistening

[0081] Buckwheat husking solution: ethanol 8%, NaHCO 3 4%, 2% sodium chloride. Prepare an aqueous solution after mixing the above-mentioned substances, adjust the temperature of the mixed solution at 40 degrees, put the buckwheat in a closed container, and process the buckwheat to be processed by high-pressure spraying, keep stirring slowly during the spraying process, and process 300 kilograms of buckwheat in each batch. 4 minutes for each treatment, keep 25 minutes after treatment, and the aqueous solution consumption is 0.5% of buckwheat weight;

[0082] The buckwheat after wetting treatment is added to the buffer silo, and enters the vibrating feeder and the material guide plate through the discharge port; through the material guide plate, it enters the shelling studio composed of the peeling rubber roller and the shelling sand board device, and ...

example 4

[0086] Example 4 Comparison Test

[0087] A kind of buckwheat hulling process comprises the steps:

[0088] The buckwheat is added to the buffer silo, and enters the vibrating feeder and the material guide plate through the feed port; through the material guide plate, it enters the shelling studio composed of the peeling rubber roller and the shelling sand board device, and the angle of the connected sand board is set to 150 degree, the tangential distance between the connected sand board and the rubber roller is 3.40mm, the peeling rubber roller is a cylindrical rubber roller, and the peeling sand board device is composed of two parallel connected sand boards, the working surface of the connected sand board is opposite to the working surface of the rubber roller , two connected sand boards are tightly connected, and the angle between the lower sand board and the horizontal bottom of the shelling studio is 50°. After shelling, the buckwheat kernels enter the finished product c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com