Contact lens processing mold

A technology for processing molds and contact lenses, applied to household appliances, other household appliances, packaging, etc., can solve the problems of user inconvenience, high cost, consumption, etc., and achieve simple manufacturing procedures, reduce production costs, and reduce process complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable your review committee members to clearly understand the content of the present invention, only the following descriptions are used together with the drawings, please refer to them.

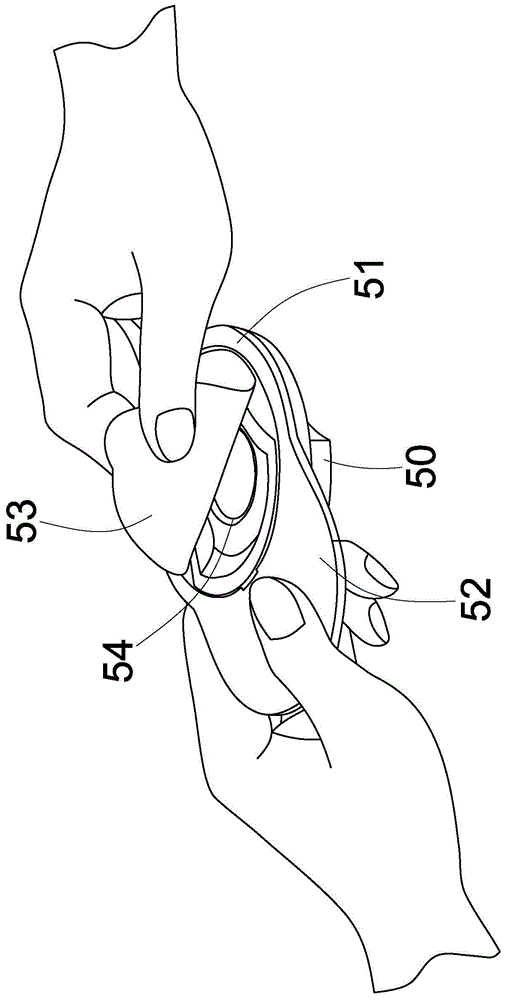

[0031] see Figure 4 As shown, it is a three-dimensional schematic view of the first preferred embodiment of the present invention. The present invention provides a contact lens processing mold, which includes: a body 10 , a concave cup 11 and a plurality of fixing holes 12 .

[0032] The body 10 has a first surface 101 and a second surface 102 opposite to each other, and one end of the body 10 is provided with a force applying portion 103. In this embodiment, the body 10 and the force applying portion 103 are rectangular, and The second surface 102 of the body 10 forms an angle with the force application portion 103, and the angle is between 120°-165° to provide an optimal force application point, and the second surface 102 is provided with a plurality of ends. part 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com