Capturing rod structure

A technology of supporting pipes and ear plates, which is applied in the direction of devices for guiding ships to the water surface, etc., can solve the problems of not meeting the requirements of speed and safety of official ships, inconvenient recovery of small boats at sea, and troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

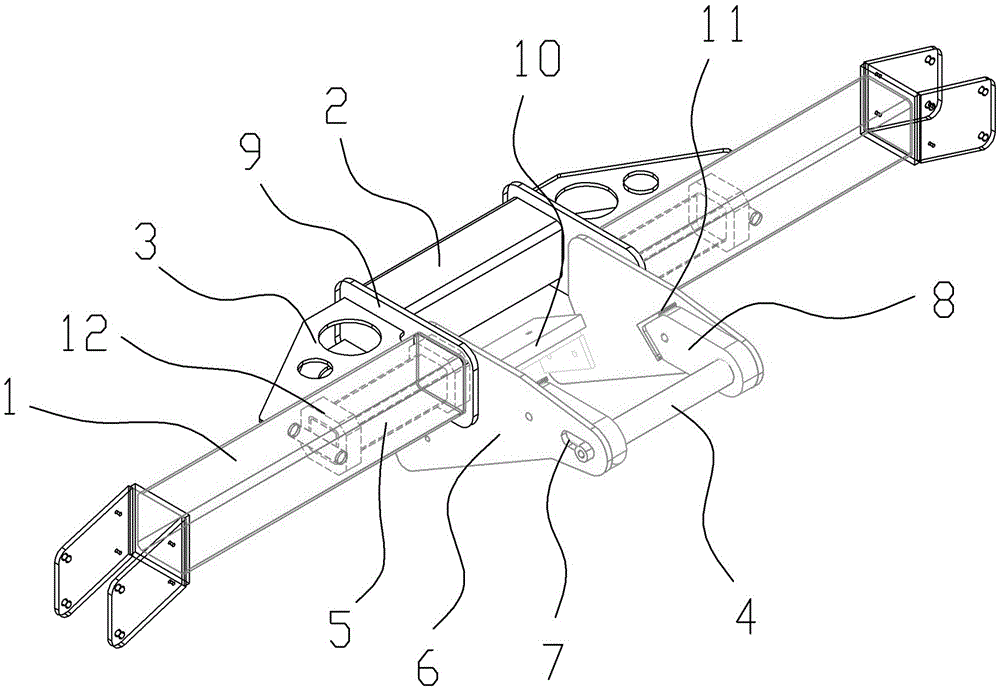

[0010] A snap-rod structure such as figure 1 As shown, it includes a square tubular support tube 1 connected to the bracket main body on both sides. The middle part of the two support tubes 1 is spaced apart and connected by connecting rods 2 on the outside thereof. The connecting rod 2 can also be a square tube, and the two ends are connected with the support pipe 1 at both ends through the gusset 3 to enhance the lateral strength and rigidity and protect the hook rod 4 from the impact of the lateral force. The opposite ends of the two support tubes 1 are respectively inserted and installed with square shafts 5, the shafts 5 and the support tube 1 form a nested structure, and the first shock absorber 12 is filled between the shaft 5 and the support tube 1; The end of the rod 5 protrudes from the opposite end of the support tube 1, and the protruding ends are respectively welded and fixed to two opposite lugs 6, and one end of the two opposite lugs 6 is respectively fixed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com