Automatic production device for organic fertilizers

A production device and organic fertilizer technology, applied in the directions of organic fertilizer, fertilization device, organic fertilizer equipment, etc., can solve the problems of poor production controllability and long fermentation cycle of organic fertilizer production, achieve good mobility, save manpower, material resources and financial resources, The effect of easy transportation and mobilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

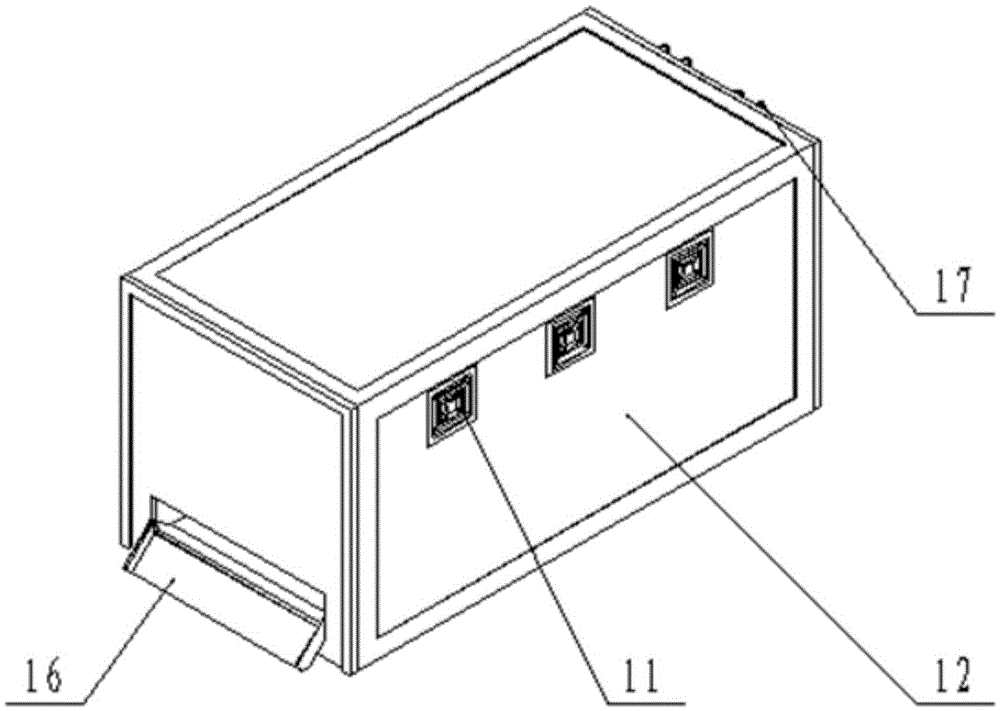

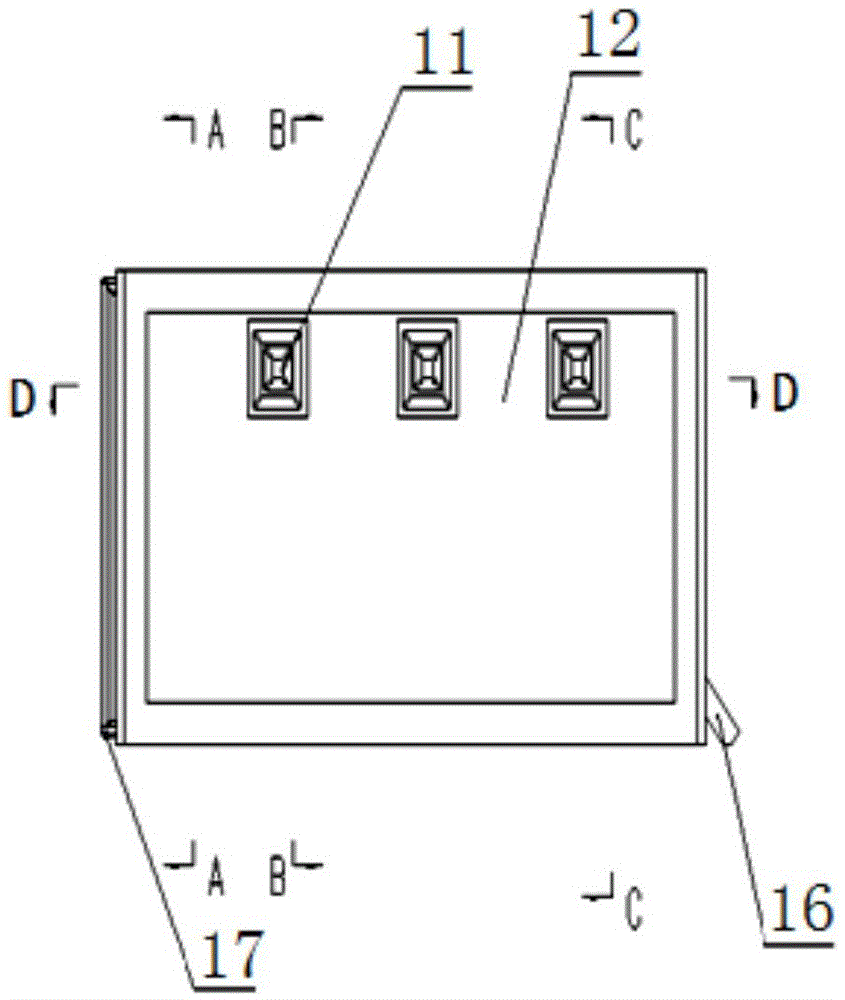

[0055] Such as Figure 1 to Figure 7 As shown, an automatic production device for organic fertilizers, including a box body 12, a fermentation chamber, a turning and mixing unit and a discharging unit,

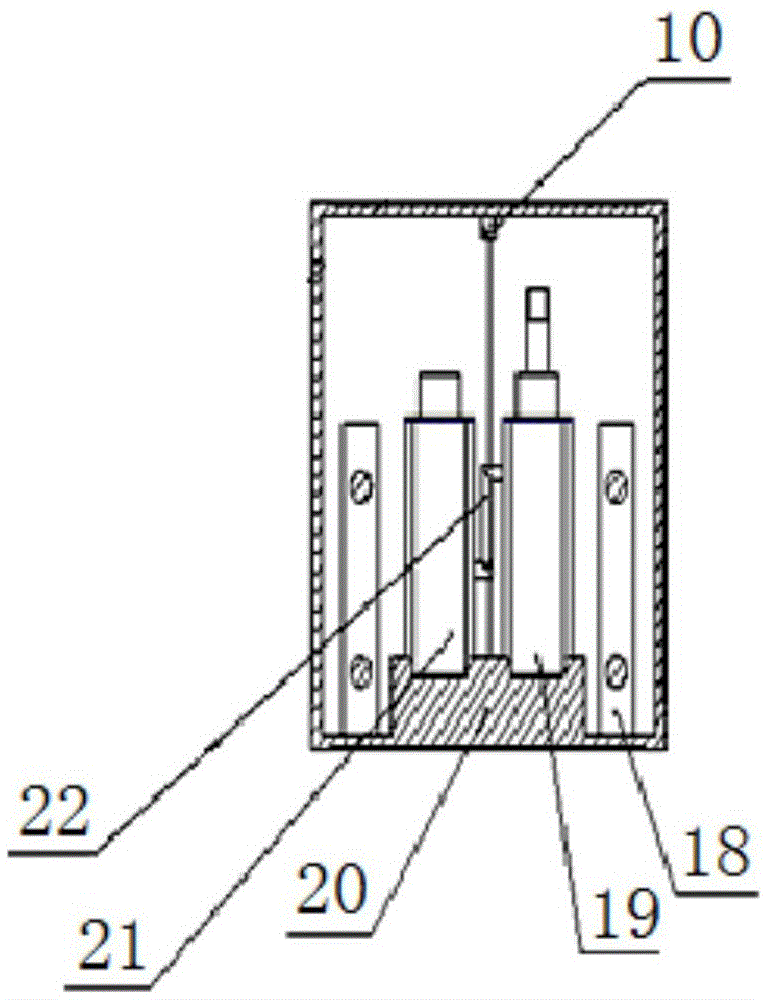

[0056] The fermentation chamber is composed of an openable and closable cover located in the middle of the box, a push plate 14 located below the cover, side walls of the box 12 and the bottom of the box 12, for placing organic fertilizers; the turning and mixing unit includes a sequence Connected fixing part 10, mounting part 5, telescopic connecting part 6, rotating shaft 4 and thrower 3, the fixing part 10 is fixed on the top of the box body, the mounting part 5 is slidably connected to the fixing part 10, and the upper end of the telescopic connecting part 6 It is connected with the installation part 5, and the lower end is connected with the turner 3 through the rotating shaft 4. When the cover is opened, the turner 3 can extend into the fermentation chamber to turn the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com