Novel prefabricated plate type damping track structure for rail traffic

A technology for rail transit and track slabs, which is applied in the field of new prefabricated slab-type vibration-damping track structures for rail transit, and can solve the problems of many construction operations, affecting construction accuracy and track-laying quality, and poor comfort of running vehicles in line smoothness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

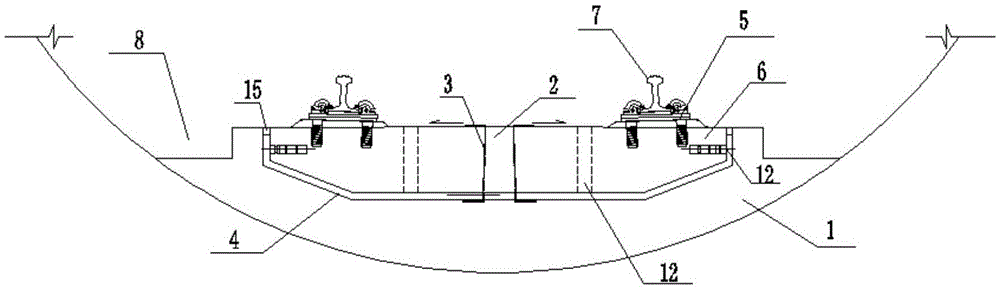

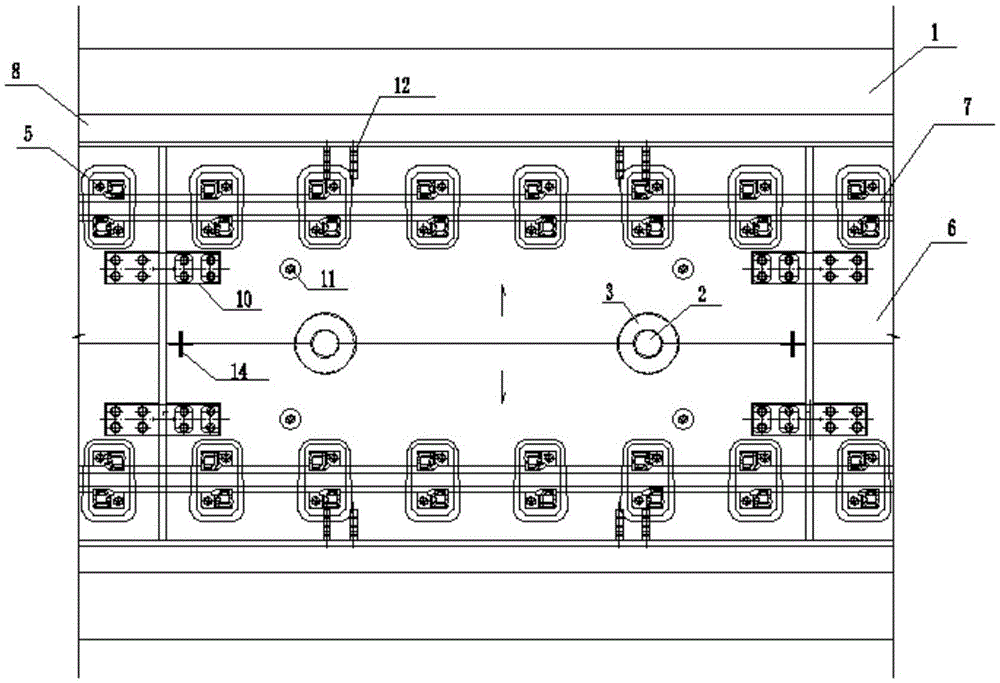

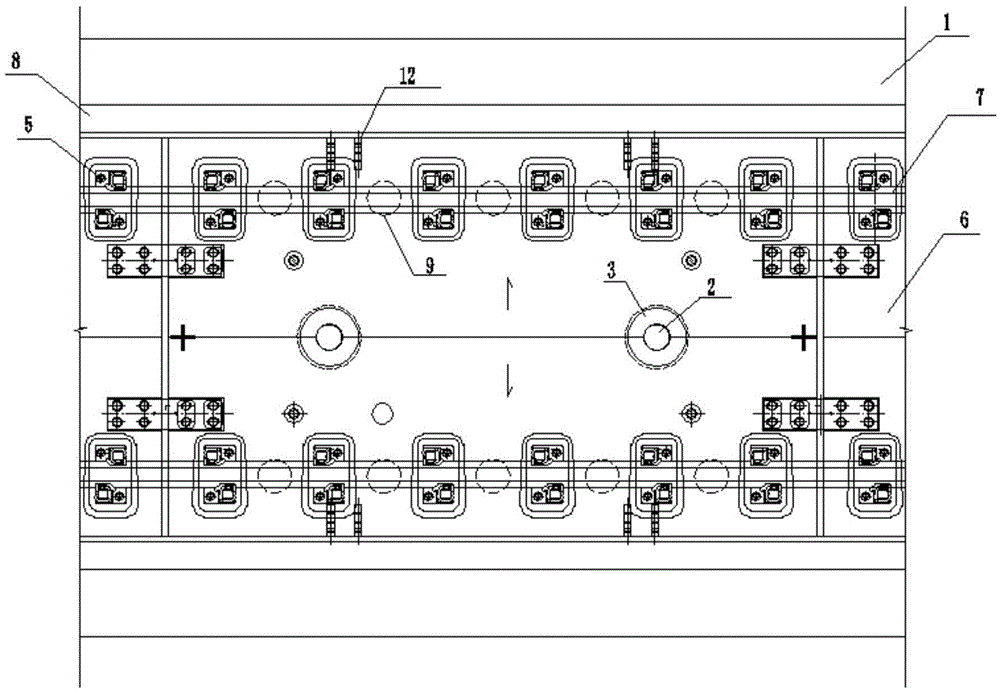

[0053] see figure 1 , The present invention relates to a prefabricated damping track structure system, said prefabricated damping track structure system is multi-layer design, including filling layer 1, elastic cushion layer 4 and track plate 6 sequentially from bottom to top.

[0054] Wherein, the filling layer 1 is the bottom layer, and the elastic cushion layer 4 is laid on the filling layer 1. Preferably, the filling layer is made of self-compacting concrete, so as to provide good fluidity when pouring, and can provide a good support effect. The end of the elastic cushion layer 4 is a sealing material (such as polyurethane caulking glue) 15 to ensure that dust, sundries, water, etc. do not enter the space between the elastic cushion layer 4 and the track 6 or between the elastic cushion layer 4 and the filling layer 1. gap.

[0055] The elastic cushion layer 4 is arranged on the filling layer 1 to provide the elastic cushioning of the filling layer 1 and avoid its rapid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com